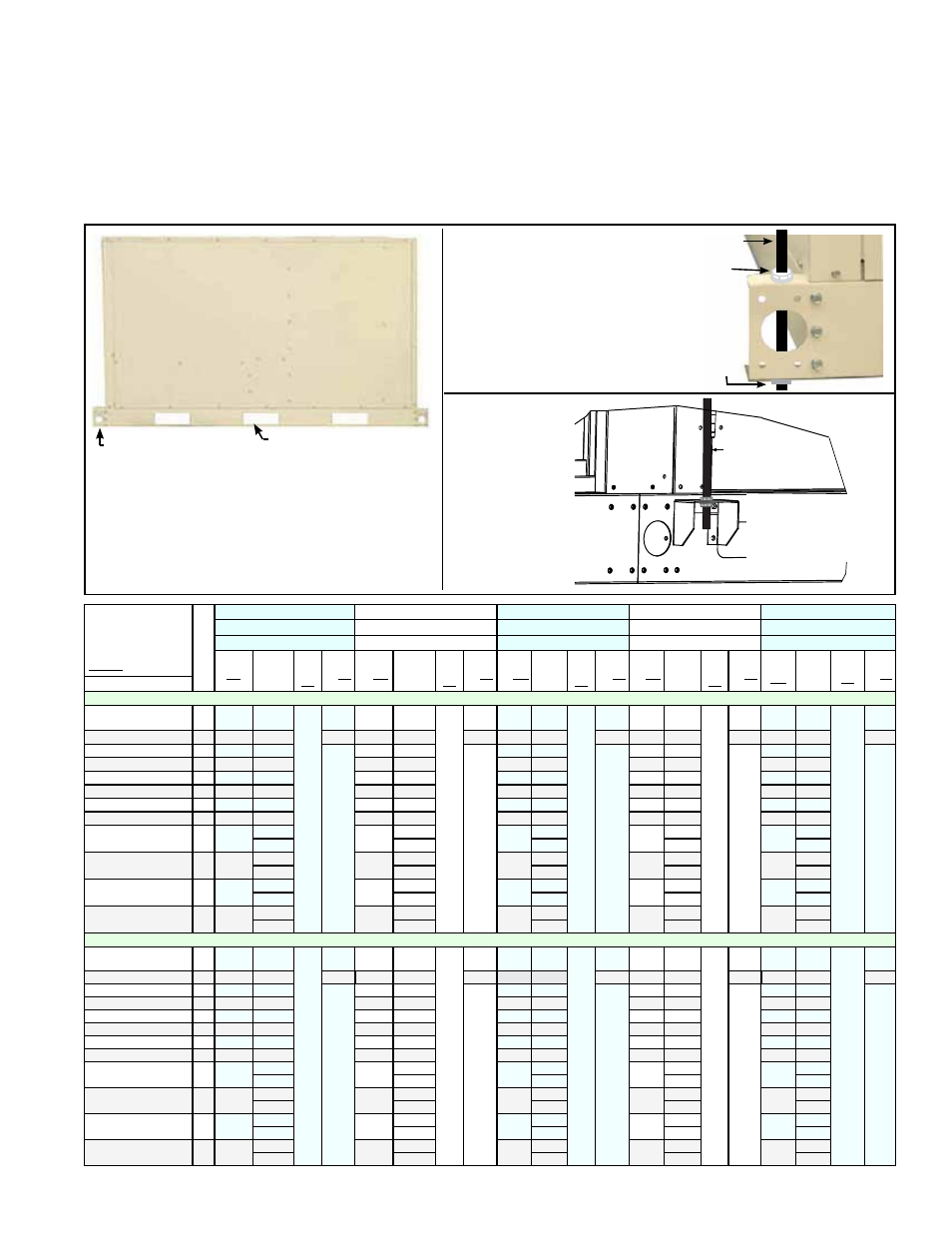

Forklift holes for moving & lifting (on both sides, Lifting hole for rigging (one at each corner), Form i-pdh/sdh/peh/shh/pxh, page 11 – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 11: Table 7a

Form I-PDH/SDH/PEH/SHH/PXH, Page 11

FIGURE 4 - Heavy

Gauge Base has Forklift

Holes and Lifting Holes

plus Holes for Attach-

ing 1/2” Threaded Rod

for Suspension

TABLE 7A -

Suspension Point

Dimensions - PDH,

SDH, PEH, and PXH

without hot water heat

Suspension Points

(qty)

PDH/SDH 75, 100

PDH/SDH 125, 150

PDH/SDH 175, 200, 225

PDH/SDH 250, 300

PDH/SDH 350, 400A

PEH 10A, 20A, 40A

PEH 15B, 30B, 60B

PEH N/A

PEH 30D, 60D, 90D, 120D

PEH 40E, 80E, 120E

PXH 000A (no heat only)

PXH 000B (no heat only)

PXH 000C (no heat only)

PXH 000D (no heat only)

PXH 000E (no heat only)

Corner to Corner

Hanger Point

Length

Discharge Corner

Hanger Point To

Intermediate

Side Hanger

Points

Corner to

Corner

Hanger

Point

Width

Intermediate

Side Hanger

Point Width

Corner to

Corner Hanger

Point Length

Discharge Corner

Hanger Point To

Intermediate

Side Hanger

Points

Corner to

Corner

Hanger

Point

Width

Intermediate

Side Hanger

Point Width

Corner to

Corner Hanger

Point Length

Discharge

Corner Hanger

Point To

Intermediate

Side Hanger

Points

Corner to

Corner

Hanger

Point

Width

Intermediate

Side Hanger

Point Width

Corner to

Corner Hanger

Point Length

Discharge

Corner Hanger

Point To

Intermediate

Side Hanger

Points

Corner to

Corner

Hanger

Point

Width

Intermediate

Side Hanger

Point Width

Corner to

Corner

Hanger Point

Length

Discharge

Corner Hanger

Point To

Intermediate

Side Hanger

Points

Corner to

Corner

Hanger Point

Width

Intermediate

Side Hanger

Point Width

Configuration

Dimensions (inches)

Blower/furnace (PDH/SDH/

PEH) or blower only (PXH)

4

56-5/8

N/A

32-5/8

N/A

56-5/8

N/A

42-5/8

N/A

72-5/16

N/A

32-5/8

N/A

72-5/16

N/A

48-7/8

N/A

72-5/16

N/A

56-7/8

N/A

with Evap Cooler (ECC)

4

87-11/16

N/A

N/A

87-11/16

N/A

N/A

103-5/8

N/A

N/A

103-5/8

N/A

N/A

103-5/8

N/A

N/A

with Mixing Box (MXB)

6

87-11/16

53-31/32

35-3/4

87-11/16

53-31/32

45-3/4

103-5/8 69-21/32

35-3/4

103-5/8 69-21/32

52

103-5/8 69-21/32

60

with Coil Cabinet (AU 5 or 6)

6

84-7/16

53-31/32

84-7/16

53-31/32

100-1/8 69-21/32

100-1/8 69-21/32

100-1/8 69-21/32

with Coil Cab (AU7)

6

109-1/2

53-31/32

109-1/2

53-31/32

125-3/16 69-21/32

125-3/16 69-21/32

125-3/16 69-21/32

with ECC & MXB

6

118-3/4

53-31/32

118-3/4

53-31/32

134-7/16 69-21/32

134-7/16 69-21/32

134-7/16 69-21/32

with ECC & AU5 or AU6

6

115-15/32 53-31/32

115-15/32 53-31/32

131-3/16 69-21/32

131-3/16 69-21/32

131-3/16 69-21/32

with ECC & AU7

6

140-7/8

53-31/32

140-7/8

53-31/32

156-1/4 69-21/32

156-1/4 69-21/32

156-1/4 69-21/32

with MXB & AU5 or AU6

8

115-15/32

53-31/32

115-15/32

53-31/32

131-3/16

69-21/32

131-3/16

69-21/32

131-3/16

69-21/32

81-25/32

81-25/32

97-1/2

97-1/2

97-1/2

with MXB & AU7

8

140-7/8

53-31/32

140-7/8

53-31/32

156-1/4

69-21/32

156-1/4

69-21/32

156-1/4

69-21/32

106-25/32

106-25/32

122-1/2

122-1/2

122-1/2

with ECC, MXB, & AU5

or AU6

8

146-1/2

53-31/32

146-1/2

53-31/32

162-1/4

69-21/32

162-1/4

69-21/32

162-1/4

69-21/32

81-25/32

81-25/32

97-1/2

97-1/2

97-1/2

with ECC, MXB, & AU7

8

171-9/16

53-31/32

171-9/16

53-31/32

187-5/16

69-21/32

187-5/16

69-21/32

187-5/16

69-21/32

106-25/32

106-25/32

122-1/2

122-1/2

122-1/2

Dimensions (mm)

Blower/furnace (PDH/SDH/

PEH) or blower only (PXH)

4

1438

N/A

829

N/A

1438

N/A

1083

N/A

1837

N/A

829

N/A

1837

N/A

1241

N/A

1837

N/A

1445

N/A

with Evap Cooler (ECC)

4

2227

N/A

N/A

2227

N/A

N/A

2632

N/A

N/A

2632

N/A

N/A

2632

N/A

N/A

with Mixing Box (MXB)

6

2227

1371

908

2227

1371

1162

2632

1769

908

2632

1769

1321

2632

1769

1524

with Coil Cabinet (AU 5 or 6)

6

2145

1371

2145

1371

2543

1769

2543

1769

2543

1769

with Coil Cab (AU7)

6

2781

1371

2781

1371

3180

1769

3180

1769

3180

1769

with ECC & MXB

6

3016

1371

3016

1371

3415

1769

3415

1769

3415

1769

with ECC & AU5 or AU6

6

2933

1371

2933

1371

3332

1769

3332

1769

3332

1769

with ECC & AU7

6

3578

1371

3578

1371

3969

1769

3969

1769

3969

1769

with MXB & AU5 or AU6

8

2933

1371

2933

1371

3332

1769

3332

1769

3332

1769

2077

2077

2477

2477

2477

with MXB & AU7

8

3578

1371

3578

1371

3969

1769

3969

1769

3969

1769

2712

2712

3112

3112

3112

with ECC, MXB, & AU5

or AU6

8

3721

1371

3721

1371

4121

1769

4121

1769

4121

1769

2077

2077

2477

2477

2477

with ECC, MXB, & AU7

8

4358

1371

4358

1371

4758

1769

4758

1769

4758

1769

2712

2712

3112

3112

3112

Whichever method is used, test lift the unit to be sure that it is secure. Then lift slowly fol-

lowing safe procedures. Lifting and suspension are the responsibility of the installer.

Depending on the type and number of optional modules, each unit has either four, six,

or eight point suspension. See

TABLE 7 A, B, or C and FIGURE 2, page 9. Extend

1/2” threaded hanger rod through both top and bottom of the base at each corner sus-

pension point. Secure with flat washers and locknuts (See

FIGURE 4, top right). When

six or eight point suspension is required, attach 1/2” threaded rod to each side hanger

bracket using a locknut and a flat washer on both the top and bottom of the hanger

bracket (See

FIGURE 4, bottom right).

• For rigging, use all four corner lifting holes

AND eyebolts placed in all side hangers of

units with side suspension points

• Use spreader bars so that lifting is with

vertical force only.

• Always test lift to be sure the unit is secure.

Forklift holes for moving

& lifting (on both sides

)

Lifting hole for rigging

(one at each corner)

1/2” Threaded

Rod

Attach with locknut

and flat washer on

top and on bottom

of each side hanger.

Suspend

from Corner

Hangers -

applies to all

units

Suspend from

Intermediate

Side Hangers

- applies to

all units with

a cooling coil

cabinet and/or

a mixing box

1/2” Threaded Rod

Locknut and flat

washer on top

Flat washer

and Locknut

on bottom

Non-Control Side of Basic Unit

(If configuration has more than

two optional modules, check

labels for recommended

lifting side using forklift.)