0 controls and operation (cont’d) – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 52

Form I-PDH/SDH/PEH/SHH/PXH, Page 52

ential of 2-1/2°F. Due to different CFM settings and outside air temperatures, the aver-

age downstream outlet temperature may not match the ductstat setting exactly. After

the installation is complete, adjust the setpoint of the ductstat to achieve the desired

average outlet air temperature.

Optional Ductstat with Electronic Remote Setpoint Module (Options AG15 and

AG16) - The factory-installed sensing probe must be field-wired to a remote tempera-

ture selector. The temperature selector has an operating range to 120°F. Follow the

wiring diagram with the unit and the manufacturer’s instructions for wiring and installa-

tion.

CAUTION: Be sure heat/cool selector switch is set at “Heat” position. There will

be one module for selecting temperature and one-stage adder module. The optional

digital display module is only in Option AG16. See

FIGURE 44.

8.2.4 Constant

Discharge Air

Temperature with

Maintained Thermal

Efficiency - Makeup

Air Heating Only

Application (Options

AG60, AG61, & AG62)

- applies to Models

PDH and SDH

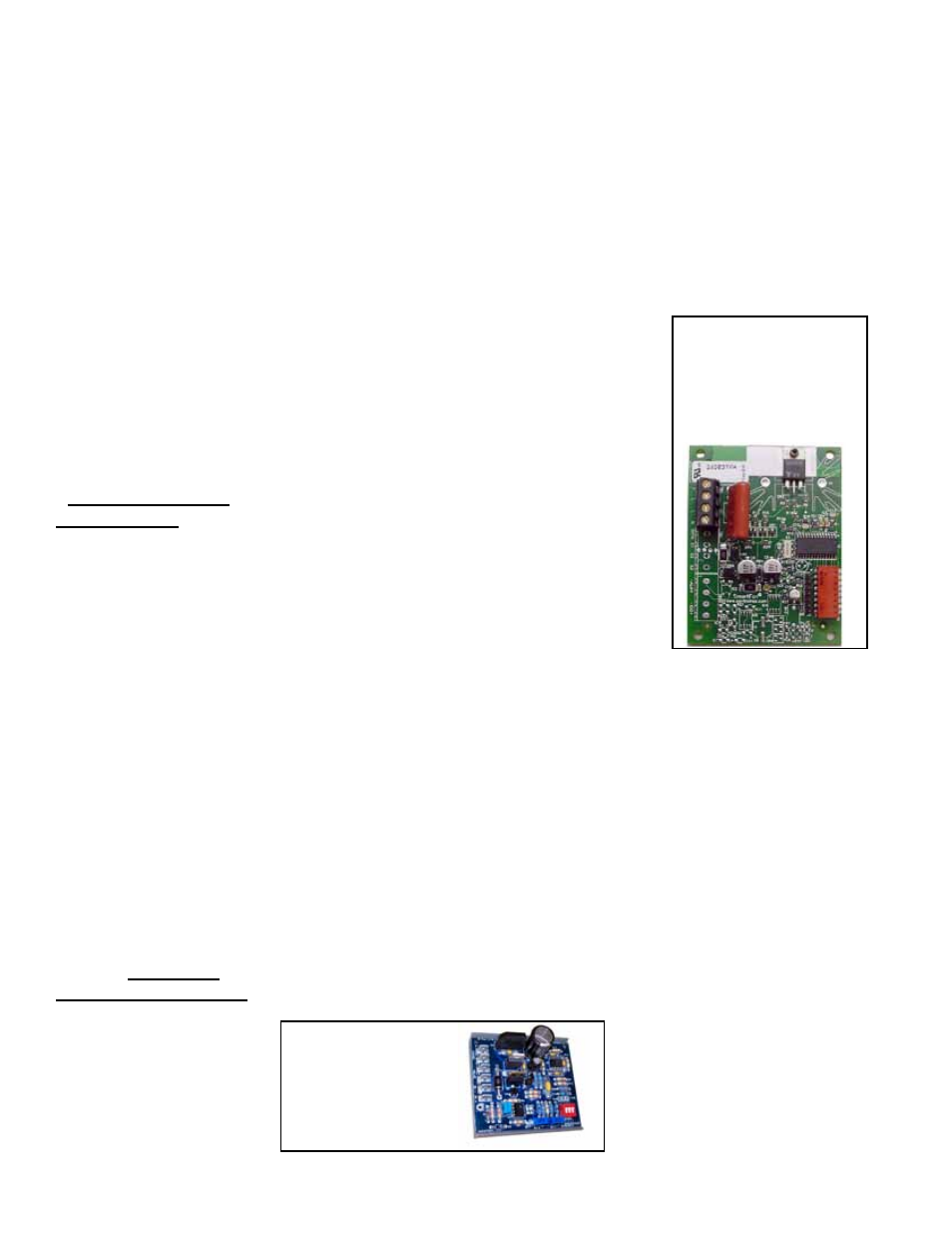

Two-Speed Venter System in Options AG60, AG61,

and AG62 - A proprietary electronically controlled venter

system provides the correct quantity of combustion air

to maintain an overall average of 81% thermal efficiency

through a range of gas inputs from 100 to 33 percent for

natural gas and through a gas input range of 100 to 40

percent for propane gas. The venter’s low speed opera-

tion is controlled by an electronic board (

FIGURE 45)

and a two-stage ductstat (either

FIGURE 43 or 44).

The proprietary electronically controlled venter system

always operates at high speed during pre-purge and

post-purge periods. Speed selection occurs after there

is a call for burner ignition.

Optional Unit-Mounted Ductstat with Capillary Tub-

ing (Option AG60) - Uses the unit-mounted control

illustrated in

FIGURE 43 with an adjustable range from

0° to 120°F. Due to different CFM settings and outside

air temperatures, the average downstream outlet tem-

FIGURE 45 -

Venter

Speed Control Board in

Control Options AG8,

AG9, AG9H, AG40, AG60,

AG61, AG62, DG1, DG2,

DG5, DG6, D12B, D12C

perature will be constant but may not match the ductstat setting exactly. After the instal-

lation is complete, adjust the setpoint of the ductstat to achieve the desired outlet air

temperature.

Optional Ductstat with Electronic Remote Setpoint Module (Options AG61 and

AG62) - The factory-installed sensing probe must be field-wired to the 0-120°F remote

temperature selector illustrated in

FIGURE 44.

The remote modules are shipped separately for field installation. Follow the wiring

diagram with the unit and the manufacturer’s instructions for wiring and installation.

CAUTION: Be sure heat/cool selector switch is set at “Heat” position. There will be one

module for selecting temperature and one-stage adder module.

The optional digital display module is used only in Option AG62. See

FIGURE 44.

FIGURE 46 -

Maxitrol Signal

Conditioner, P/N

134170, used in

Options AG40,

DG2, and DG6

8.2.5 Modulation Gas

Control with Field-

Supplied Digital

Control (Option

AG40) - applies to

Models PDH and SDH

Optional Modulation Gas Control with Field-Supplied Controller (Option AG40) -

With this control, the modulation gas heating system is identical to digital Options DG2

and DG6 on page 53. The programmable digital controller is not supplied. The unit is

equipped with a Maxitrol signal conditioner (

FIGURE 46) that accepts an input signal of

either 4-20 milliamps or 0-10 volts from a field-supplied controller and converts it to the

0-20 volt DC current required to control the modulating valve. Temperature selection or

building management is controlled by customer-supplied software.

8.0 Controls and

Operation

(cont’d)

8.2 Analog Controls

for Heating or

Heating/Makeup

Air (cont’d)

8.2.3 Two-Stage Operation - Makeup Air Heating Only Application

(Option AG3, AG15, or AG16) (cont’d)