3 wiring diagram and unit wiring requirements, 4 control wiring, 1 control wiring requirements – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 45: 2 analog or digital controls

Form I-PDH/SDH/PEH/SHH/PXH, Page 45

WARNING - applies to Models PDH, SDH, and SHH:

If you turn off the power supply, turn off the gas.

Optional On/Off Switch, Option BA6 - The unit my be equipped with a cabinet-

mounted non-fusible, lockable, service on/off switch. The switch is conveniently located

on the control side of the unit.

Optional Phase Loss or Low/High Voltage Protection, Opt BF15 or BF14 - A

3-phase system may be equipped with an optional phase loss protection device.

Option BF15 is an auto-reset control that shuts down the unit on phase loss or phase

reversal. Option BF14 performs the same function but will also shut down the unit on

high or low voltage condition.

CAUTION: If any of the original wire as supplied with the appliance

must be replaced, it must be replaced with wiring material having a

temperature rating of at least 105°C, except for sensor lead wires which

must be 150°C. See Hazard Levels, page 2.

7.3 Wiring Diagram

and Unit Wiring

Requirements

Each unit has a custom wiring diagram in the control compartment. All optional elec-

trical components ordered with the unit are shown on the wiring diagram. Codes for

options ordered are listed across the bottom of the diagram. To identify option codes,

see list in the

APPENDIX on page 68.

Keep the wiring diagram and all manuals for future reference.

7.4 Control Wiring

The heater is equipped with a low voltage (24V) control circuit. A wiring diagram is in

the high voltage electrical compartment.

Control wiring connected to a thermostat, a switch, a discharge air sensor, a remote

temperature selector or sensor, an amplifier, or the valve must not be run close to or

inside conduit with power or ignition wires.

7.4.1 Control Wiring Requirements

Digital Control Signal Wiring Recommendations and Requirements

For optimum temperature control performance, the manufacturer recommends that the

analog and digital inputs (zone sensors, discharge air sensors, etc.) connected to the

main controller (used in heating/cooling control DG and D12 Options) be routed to the

unit in one of the following manners:

1) In separate conduits, isolated from 24 VAC controls and line voltage power to the

unit, OR

2) If the digital sensor wires are to be run in the same conduit as the 24 VAC control

wiring, the sensor wiring must be completed using shielded cable and bundled

separately from the 24 VAC control wiring. The shield must be drained at the unit

and taped on the opposite end.

See

TABLE 30 for digital control sensor wire gauge and length requirements.

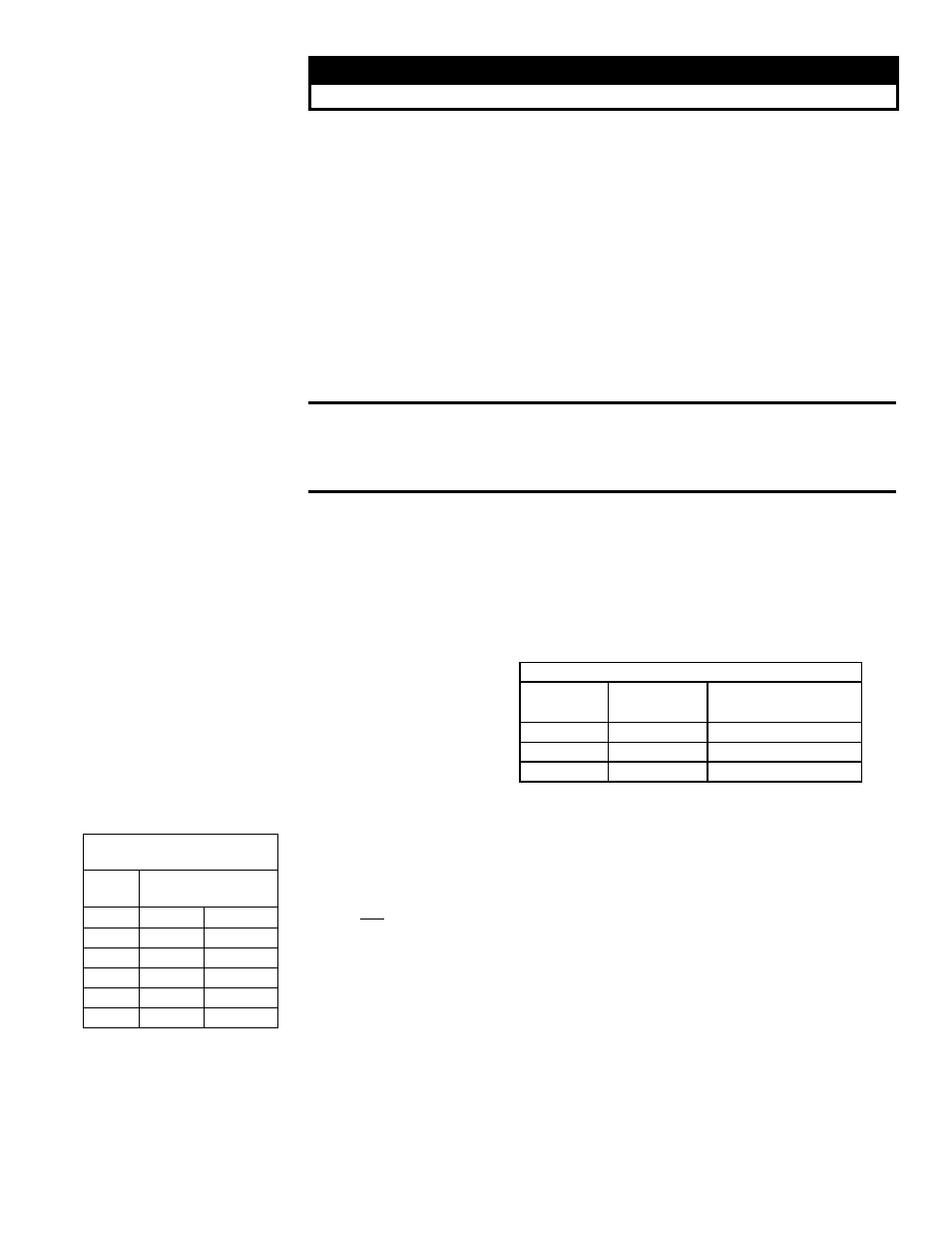

TABLE 30 - Digital

Control Sensor Wire

TABLE 29 - 24V Control

Wiring Gauge and

Length Requirements

7.4.2 Analog or Digital

Controls

Type of control varies with option selection (identified on the unit wiring diagram). Con-

trol may be analog or digital depending on the control option selected. Option AG3,

AG15, AG16, AG58, AG60, AG61, and AG62 controls are analog; Option DG1, DG2,

DG5, DG6, D12B, D12C, D12D, D12E, D12F, and D12G controls are digital. Option

AG40 is designed for digital control from a field-supplied source. Optional controls are

identified on the wiring diagram supplied with the heater.

24V Field Control Wiring Length/Gauge

Total Wire

Length

Distance from

Unit to Control

Minimum Recommended

Wire Gauge

150ft (46M)

75ft (23M)

18

250ft (76M)

125ft (38M)

16

350ft (107M)

175ft (53M)

14

Maximum Sensor Wire Length

for less than 1°F Signal Error

Wire

Gauge

Maximum Sensor Wire

Length (Digital Control)

AWG

Feet

Meters

14

800

244

16

500

152

18

310

94

20

200

61

22

124

38