4 unit inlet air (supply air), 0 mechanical (cont’d), 3 combustion air requirements (cont’d) - model pdh – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 22

Form I-PDH/SDH/PEH/SHH/PXH, Page 22

Confined Space:

A space whose

volume is less than

50 cubic feet per 1000

BTUH of the installed

appliance input rating.

FIGURE 14 - Definition

of Confined Space and

Required Openings for

Combustion Air

(3)

(3)

(1)

(1)

(2)

(2)

Confined

Space

6.4 Unit Inlet Air

(Supply Air)

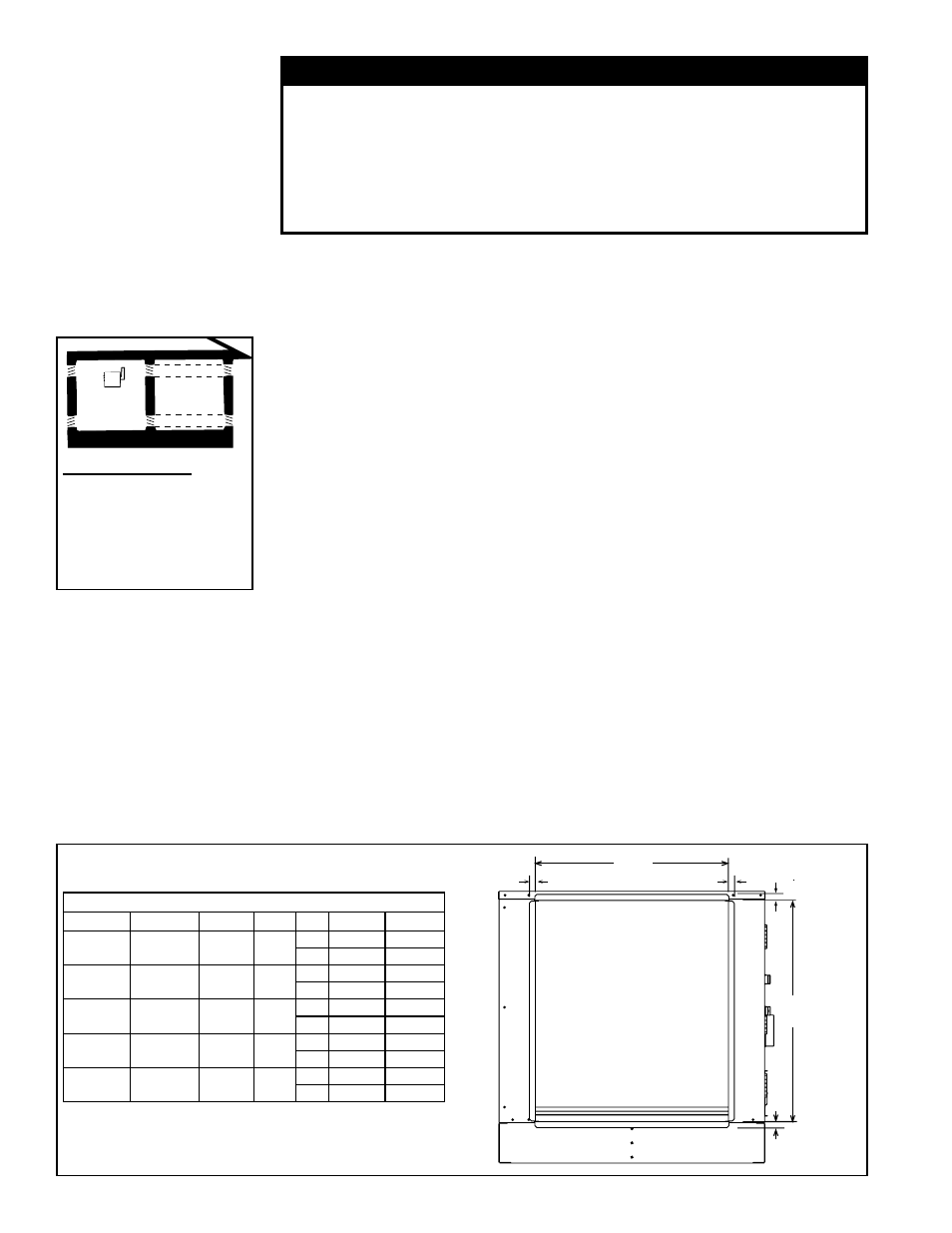

FIGURE 15 - Optional Inlet Air Duct Flange

on the Blower Cabinet, Option AR5

X

Blower Cabinet

Inlet Air Opening

with Duct Flange

Option AR5

Y

3/4(19mm)

3/4(19mm)

3/4

(19mm)

3/4

(19mm)

TABLE 12 - Dimensions of Optional Inlet Air Duct Flange

PDH/SDH

PEH

SHH

PXH

X

Y

75/100

10A/ 20A/

40A

N/A

000A

inches

24-1/2

25-1/16

mm

622

636

125/150

15B/30B/

60B

N/A

000B

inches

34-1/2

25-1/16

mm

876

636

175/200/

225

N/A

130/180 000C

inches

24-1/2

37-5/16

mm

622

948

250/ 300 30D/ 60D/

90D/120D

260

000D

inches

40-3/4

37-5/16

mm

1035

948

350/400A 40E/80E/

120E

350

000E

inches

48-3/4

37-5/16

mm

1238

948

Combustion Air Requirements for a Heater Located in a Confined Space

Do not install a PDH unit in a confined space without providing wall openings leading

to and from the space. Provide openings near the floor and ceiling for ventilation and

air for combustion as shown in

FIGURE 14, depending on the combustion air source

as noted in Items 1, 2, and 3 below.

Add total BTUH of all appliances in the confined space and divide by figures below for

square inch free area size of each (top and bottom) opening.

1. Air from inside the building -- openings 1 square inch free area per 1000 BTUH.

Never less than 100 square inches free area for each opening. See

(1) in FIGURE

14.

2. Air from outside through duct -- openings 1 square inch free area per 2000

BTUH. See

(2) in FIGURE 14.

3. Air direct from outside -- openings 1 square inch free area per 4000 BTUH. See

(3) in FIGURE 14.

NOTE: For further details on supplying combustion air to a confined space, see the

National Fuel Gas Code NFPA54/ANSI Z223.1 (latest edition).

6.0 Mechanical

(cont’d)

WARNING

Model PDH power-vented heaters are designed to take

combustion air from the space in which the unit is installed

and are not designed for connection to outside combustion

air intake ducts. Connecting outside air ducts voids the

warranty and could cause hazardous operation. See Hazard

Levels, page 2.

Depending on the Model and how the unit was ordered, the blower can have a variety

of factory-installed inlets. The cabinet end can be full open with or without a screen;

the cabinet end can have a duct flange for attaching inlet air ductwork; or the cabinet

end can have a two-position damper with duct flange. If filters were ordered, the inlet

will have a filter rack with filters.

Or, the unit can have an attached combination of modules including a mixing box with

either one or two inlets with duct flanges and a variety of controls, a cooling coil mod-

ule, and/or an evaporative cooling module.

6.4.1 Optional Inlet

Duct Flange (factory

installed), Option AR5

Dimensions for attaching ductwork are shown in

TABLE 12. The optional duct flange

is 1-1/2” (38mm) long with a 3/4” (19mm) wide flange on all sides. The inlet air duct

should be attached and sealed. Ductwork must have a free area equal to the duct con-

nection.

6.3 Combustion Air

Requirements

(cont’d) - Model

PDH