6 other optional electrical components – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 49

Form I-PDH/SDH/PEH/SHH/PXH, Page 49

The electric heat section has either heating only analog controls (Option EG1 or EG2)

or digital heating/cooing controls (Option D12E or D12D). With Option EG1, operation

of the heating elements is controlled by a single stage thermostat. With Option EG2,

the heat section provides two-stages of heat in response to a two-stage thermostat.

Digital control is either two stage (Option D12E) or modulating (Option D12D). See

Paragraph 8.3.2 and the control instruction form (CP-PREEVA-D12) for control infor-

mation.

7.6 Other Optional

Electrical

Components

Optional electrical components ordered with the unit are on the wiring diagram. For a

list of wiring diagram option codes and descriptions, see

APPENDIX, page 68.

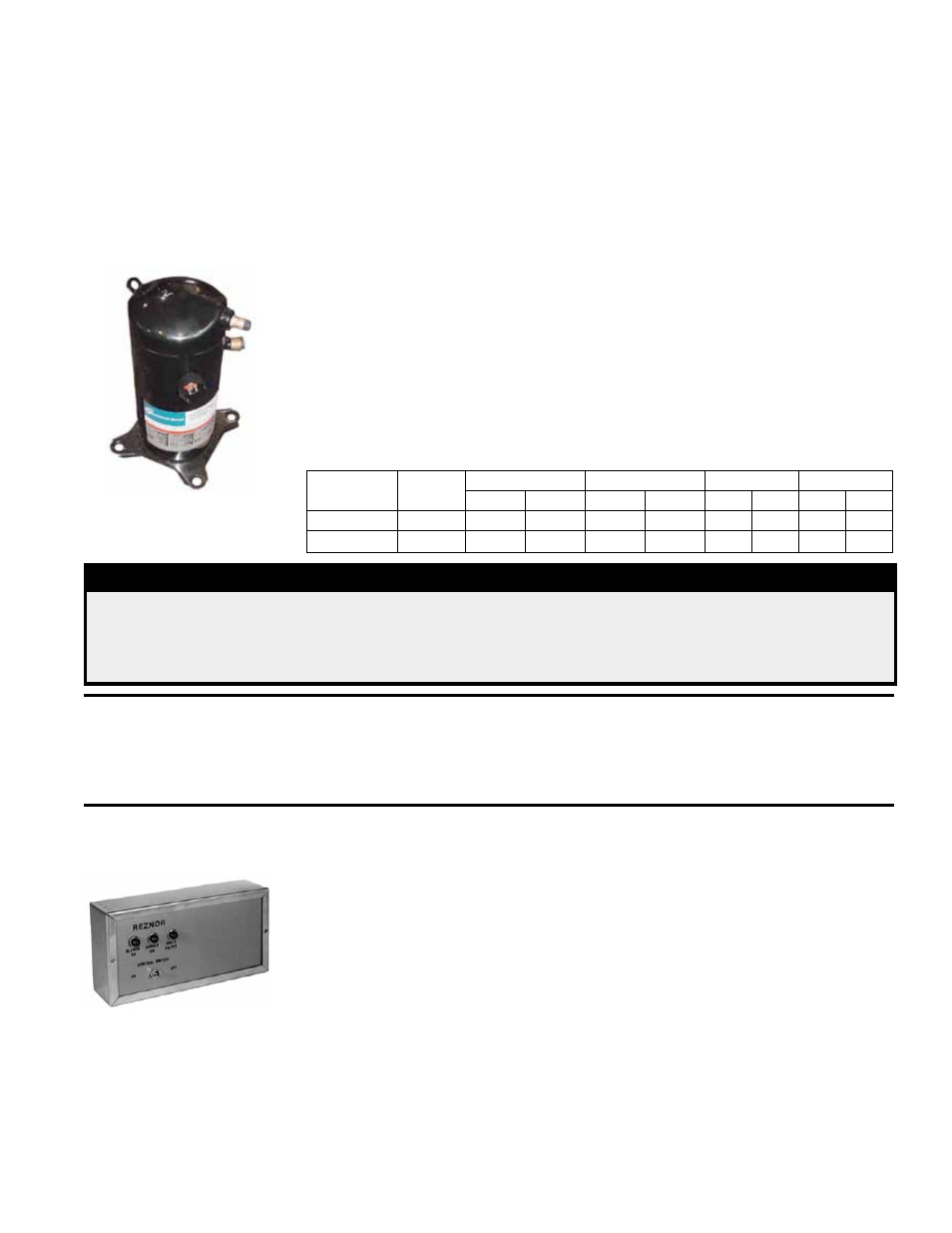

7.6.1 Reheat Module (Option AU7L or AU7R) Compressor - Models

PDH, SDH, SHH, PEH, PXH

The compressor in the optional reheat module is a high efficiency hermetic scroll type

that is factory charged with R410A refrigerant. The compressor has a low pressure

cutoff (LPCO) switch for protection against damage due to a loss of charge. This pro-

tection prevents short cycling on the internal overload (IOL) which can pump the oil

out of the compressor. The compressor also has a manual reset high pressure cutout

(HPCO).

NOTE: See Operation/Maintenance Form O-PREEVA (in the Literature Bag), for addi-

tional information on compressor maintenance and R410A refrigerant.

Compressor

Model

ARI

Tonnage

208/240 V 1 PH

208/240 V 3 PH

460 V3 PH

575 V3 PH

RLA

LRA

RLA

LRA

RLA

LRA RLA

LRA

ZP29K5

2.4

14.1

77.0

9.0

71.0

5.6

38.0

3.8

36.5

ZP57K3

4.8

30.1

158.0

20.5

155.0

9.6

75.0

7.6

54.0

Compressor - Reheat

circuit is charged with

R410A Refrigerant.

TABLE 33 - Reheat Module Compressor

DANGER

The reheat circuit contains R410A high pressure refrigerant. Hazards exist that could result

in personal injury or death. Installation, maintenance, and service should only be performed

by an HVAC technician qualified in R410A refrigerant and using proper tools and equip-

ment. DO NOT USE service equipment or tools designed for R22 refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service

procedures include the adding or removing of refrigerant, the service technician

must comply with all federal, state and local laws. The procedures discussed in

this manual should only be performed by a qualified HVAC technician.

7.6.2 Remote Console

for Controls

If the system includes an optional control console, it is shipped separately for field

installation. A selection of remote consoles is available with a variety of combinations

of factory-mounted controls. All consoles include burner and blower indicator lights

and may include a dirty filter indicator light (see below); a cooling on indicator light;

an on/off switch; a summer/winter/off control switch; a heat/vent/cool system switch;

and/or a potentiometer for damper control. The thermostat or room command module

may also be mounted on the console. Depending on the console selected, it may be

10-3/4” (273mm) or 15-3/4” (400mm) in length. All consoles are 7-5/8” (194mm) high

and 2-5/8” (67mm) deep. Consoles may be flush or recess mounted. If recessing (not

using the mount ring) subtract 7/8” (22mm) from the height and width.

Wire the 24V controls on the remote console according to the wiring diagram. Refer to

TABLE 29 on page 45 for minimum control wire gauge by length.

Dirty Filter Switch - If there is a dirty filter indicator light on the console, there is a dirty

filter switch in the electrical compartment. After the unit is started, before continuous

operation, the dirty filter switch must be set.

Instructions for Setting Dirty Filter Switch (See FIGURE 42.) - With clean filters

in place; all doors closed (except electrical compartment); and the blower opening,

increase the pressure setting by adjusting the setscrew on the switch clockwise until