7 unit discharge, 0 mechanical (cont’d), 4 ultra-violet light, option uv2 – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 36: Condensate drain use

Form I-PDH/SDH/PEH/SHH/PXH, Page 36

Seasonal Usage - At the beginning of the cooling season, inspect and clean the entire

cooling coil cabinet including the condensate drain pan. Thoroughly clean dirt, algae,

grease, and other contaminants. Inspect condensate drain pans, traps, and piping; fill

traps with water to ensure proper operation.

Year Round Usage - Climates or applications with cooling requirements year round

require more frequent inspections of the cooling coil cabinet and condensate drains.

Condensate Drain Use

If the cooling module was ordered with an optional ultra-violet light, the fixture is factory

installed but the bulb and other components are shipped in the blower compartment for

field installation. Follow the instructions on the option installation form shipped in the

parts bag. Option UV2 ultra-violet light requires its own power supply and disconnect

switch.

6.6.4 Ultra-Violet

Light, Option UV2

CAUTION: Do not touch bulb glass without gloves. Oil from fingerprints

will permanently etch bulb and weaken structure. Clean bulb after

handling.

WARNING

Do not use UVC lights for service lighting. Never expose eyes or

skin to ultra-violet light from any source.

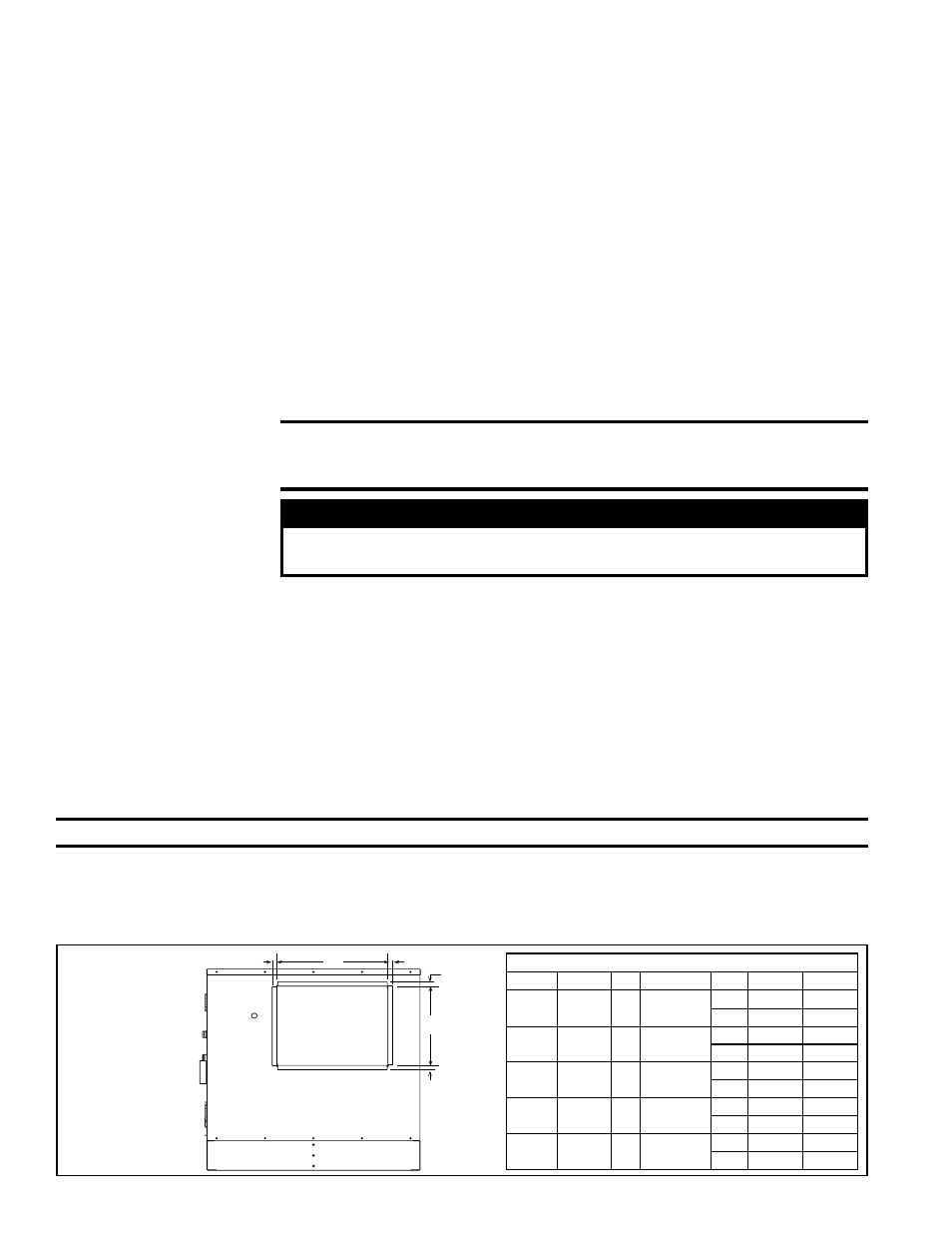

6.7 Unit Discharge

Model PEH units require attachment of an outlet duct. They are equipped with a fac-

tory-attached discharge duct flange as shown in

FIGURE 30.

Model SDH, PDH, PXH, and SHH units may have ductwork or may discharge directly

into the space. Depending on which option was ordered, the discharge opening is

equipped with either an attached duct flange, factory-installed horizontal louvers, fac-

tory-attached horizontal and vertical louvers, or is an opening designed for field instal-

lation of an optional nozzle (Paragraph 6.7.4). If an outlet option is not selected, see

dimensions in

FIGURE 2, page 9.

Factory-installed horizontal louvers (Option AX2) are spring mounted in the discharge

opening and do not have a frame. If there are factory-installed horizontal and vertical

louvers (Option AX3), the frame adds approximately 4” (102mm) to the length of the

cabinet. Adjust louvers for desired discharge airflow.

6.7.1 Louvers, Option

AX2 or AX3 - PDH,

SDH, SHH

6.7.2 Discharge Duct Flange (factory installed

)

, Std on PEH; Option AX4 on PDH, SDH, SHH,

or PXH (without hot water heat)

X

Y

3/4(19mm)

3/4(19mm)

3/4

(19mm)

3/4

(19mm)

Discharge Opening

with Duct Flange

Std - PEH;

Opt AX4 - PDH,

SDH, SHH, PXH (no heat)

TABLE 22 - Dimensions of Discharge Duct Flange

PDH/SDH

PEH

SHH PXH (no heat)

X

Y

75, 100

10A, 20A,

40A

N/A

000A

inches

17-9/16

13-9/16

mm

446

345

125, 150

15B, 30B,

60B

N/A

000B

inches

27-9/16

13-9/16

mm

700

345

175, 200,

225

N/A

130,

180

000C

inches

20-3/4

22-13/16

mm

527

580

250, 300

30D, 60D,

90D, 120D 260

000D

inches

28-5/8

22-13/16

mm

727

580

350, 400A 40E, 80E,

120E

350

000E

inches

38-5/16

22-13/16

mm

973

580

FIGURE 30 -

Dimensions

of Discharge

Duct Flange

(factory

installed)

Dimensions for attaching ductwork are shown in

TABLE 22. The discharge duct flange is 4” (102mm) long with a 3/4”

(19mm) wide flange on all sides. See requirements and recommendations below for sizing and attaching ductwork.

6.0 Mechanical

(cont’d)

6.6 Cooling Module

- Option AU on

PDH, SDH, PEH,

SHH, and PXH

(cont’d)

The combination of airborne particles and moisture in the air handler can result in

algae formation in the drain pan and traps. The traps must be cleaned regularly to

avoid blockage that can slow or stop water flow, resulting in backup into the system.

If the drains have a cleanout opening (

FIGURE 29B), be sure to close the opening

after cleaning.

Drain Trap (cont’d)

CAUTION: To avoid getting burned, wear gloves if adjusting louvers during heat operation.