0 mechanical (cont’d), High altitude capacity changes, Form i-pdh/sdh/peh/shh/pxh, page 18 – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 18

Form I-PDH/SDH/PEH/SHH/PXH, Page 18

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result

in unregulated

manifold pressure

causing excess

overfire and heat

exchanger failure.

High Altitude Capacity

Changes

The input and/or the capacity of the heater changes with altitude.

TABLE 11A lists inputs and capacities at altitudes from sea level to 9,000 ft (2745M)

for Models PDH and SDH installed in the U.S. and to 4,500 ft (1373M) for Canadian

installations.

TABLE 11B lists inputs and capacities for Model SHH.

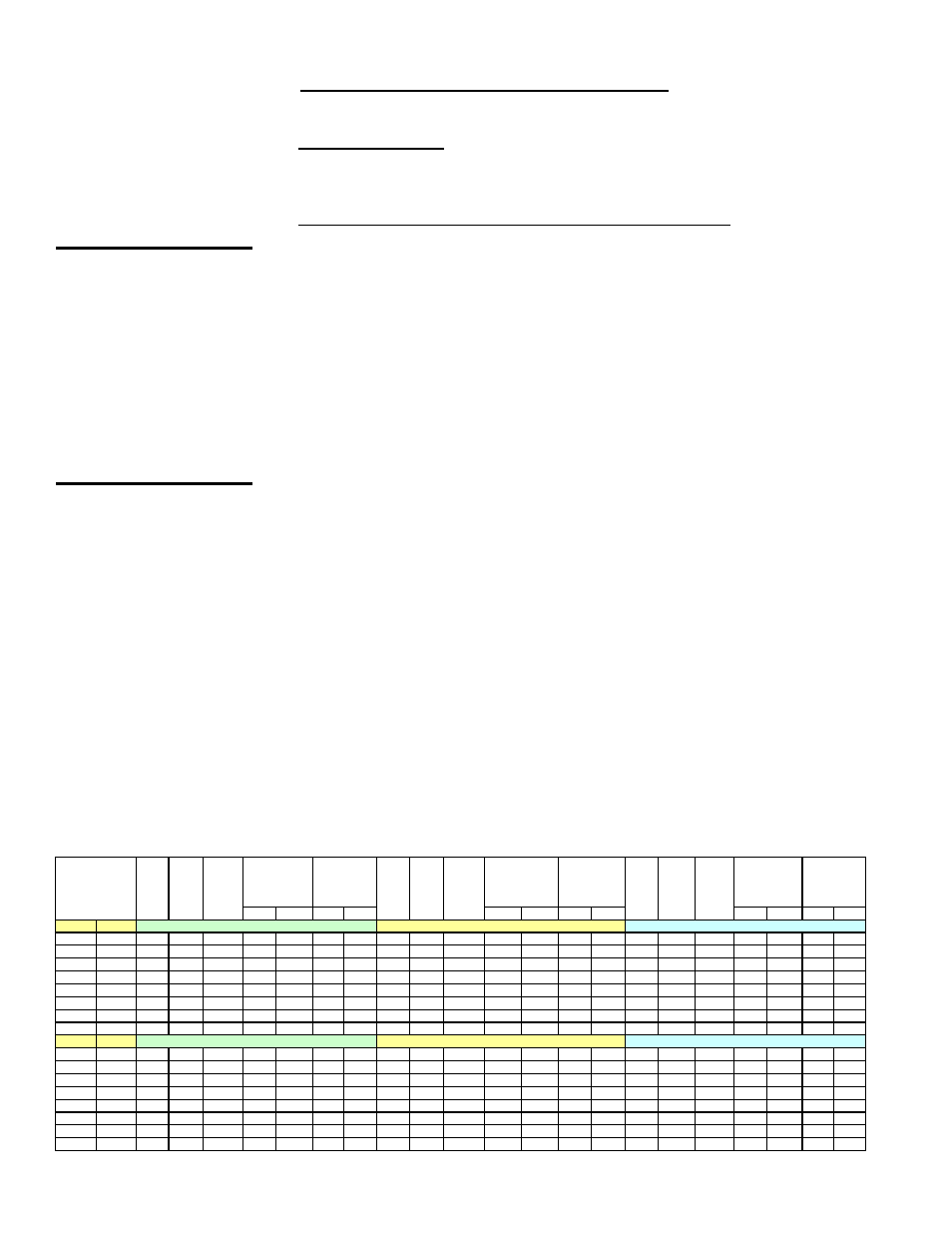

TABLE 11A - BTUH Inputs and Capacities by Altitude for Models PDH and SDH

Instructions for High Altitude Derate (cont’d)

6.0 Mechanical

(cont’d)

6.1 Gas Heat

Section Piping

and Pressure

- Models PDH,

SDH, and SHH

(cont’d)

3. Single-Stage and Two-Stage High Fire Adjustment - Turn the knob or switch on

the top of the valve to “ON”. Remove the cap from the pressure adjusting screw

and adjust the outlet pressure to the full rate pressure selected from

TABLE 10.

Two Stage Low Fire - Disconnect the wire from the “HI” terminal on the gas valve

and check low fire pressure. To adjust, turn the low pressure regulator screw to

achieve the “2-Stage Low Fire” pressure listed

for the applicable gas control

(TABLE 10). Re-connect the wire to the gas valve.

Electronic Modulation Options AG40, DG2, DG6, and D12B - The electronic

modulation valve itself has no high fire adjustment. The only adjustment on the

modulation valve is the low-pressure bypass setting which is factory set and does

not require field adjustment for high altitude operation.

However, if the elevation on the rating plate does not match the elevation of the

installation, a full rate adjustment is required at the outlet of the combination valve.

To make the full rate adjustment, adjust the outlet pressure of the combination gas

valve when the modulating valve is fully open (there must be a minimum of a 20

VDC signal at the electronic modulating valve to ensure that it is fully open). Set

the outlet pressure of the combination valve to the pressure shown in

TABLE 10.

4. Turn up the thermostat. (NOTE: On Model SDH and SHH, depress and hold the

door safety switch.) Cycle the burner once or twice to properly seat the adjustment

spring in the valve.

Re-check the pressure(s). When the outlet pressure(s) is right for the installation,

remove the manometer and replace the cap. Check for leak at the pressure tap fit-

ting.

5. With the heater operating, determine that the inlet (supply) pressure to the heater

for natural gas is between 5 inches w.c.

(or as noted on the rating plate) and

14 inches w.c. and for propane between 11 and 14 inches w.c. Take this reading

as close as possible to the heater. (Heaters are equipped with a gas valve that

has an inlet pressure tap.) If the inlet (supply) pressure is not within the specified

range, the inlet (supply) pressure must be corrected and Steps 3 and 4 repeated.

6. Find the High Altitude Adjustment label in the literature bag that contained these

instructions. Using a permanent marker, fill-in the appropriate information from

TABLE 11A or 11B. Affix the label to a clean, dry, and conspicuous location on the

outside of the heater access panel.

ALTITUDE

Normal

Input

Thermal

Output

Capacity

2-Stage

Minimum

Input

(applies to

AG2, AG3,

AG15,

AG16)

2-Stage with Venter

Motor Controller

Minimum Input

(applies to AG60,

AG61, AG62, DG1,

DG5, D12C)

Modulation

Minimum Input

(applies to Options

AG8, AG9, AG9H,

AG40, DG2, DG6,

D12B)

Normal

Input

Thermal

Output

Capacity

2-Stage

Minimum

Input

(applies

to AG2,

AG3, AG15,

AG16)

2-Stage with Venter

Motor Controller

Minimum Input

(applies to AG60,

AG61, AG62, DG1,

DG5, D12C)

Modulation

Minimum Input

(applies to Options

AG8, AG9, AG9H,

AG40, DG2, DG6,

D12B)

Normal

Input

Thermal

Output

Capacity

2-Stage

Minimum

Input

(applies to

AG2, AG3,

AG15,

AG16)

2-Stage with Venter

Motor Controller

Minimum Input

(applies to AG60,

AG61, AG62, DG1,

DG5, D12C)

Modulation

Minimum Input

(applies to Options

AG8, AG9, AG9H,

AG40, DG2, DG6,

D12B)

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Feet

Meters

Size 75

Size 100

Size 125

0-2000

0-610

75,000

60,750

52,500

24,750

30,000

18,750

30,000

100,000

81,000

70,000

33,000

40,000

25,000

40,000

125,000

101,250

87,500

41,250

50,000

31,250

50,000

2001-3000

611-915

70,500

57,105

49,350

23,265

28,200

17,625

28,200

94,000

76,140

65,800

31,020

37,600

23,500

37,600

117,500

95,175

82,250

38,775

47,000

29,375

47,000

3001-4000

916-1220

69,000

55,890

48,300

22,770

27,600

17,250

27,600

92,000

74,520

64,400

30,360

36,800

23,000

36,800

115,000

93,150

80,500

37,950

46,000

28,750

46,000

4001-5000

1221-1525

67,500

54,675

47,250

22,275

27,000

16,875

27,000

90,000

72,900

63,000

29,700

36,000

22,500

36,000

112,500

91,125

78,750

37,125

45,000

28,125

45,000

5001-6000

1526-1830

66,000

53,460

46,200

21,780

26,400

16,500

26,400

88,000

71,280

61,600

29,040

35,200

22,000

35,200

110,000

89,100

77,000

36,300

44,000

27,500

44,000

6001-7000

1831-2135

64,500

52,245

45,150

21,285

25,800

16,125

25,800

86,000

69,660

60,200

28,380

34,400

21,500

34,400

107,500

87,075

75,250

35,475

43,000

26,875

43,000

7001-8000

2136-2440

63,000

51,030

44,100

20,790

25,200

15,750

25,200

84,000

68,040

58,800

27,720

33,600

21,000

33,600

105,000

85,050

73,500

34,650

42,000

26,250

42,000

8001-9000

2441-2745

61,500

49,815

43,050

20,295

24,600

15,375

24,600

82,000

66,420

57,400

27,060

32,800

20,500

32,800

102,500

83,025

71,750

33,825

41,000

25,625

41,000

Feet

Meters

Size 150

Size 175

Size 200

0-2000

0-610

150,000

121,500

105,000

49,500

60,000

37,500

60,000

175,000

141,750

122,500

57,750

70,000

43,750

70,000

200,000

162,000

140,000

66,000

80,000

50,000

80,000

2001-3000

611-915

141,000

114,210

98,700

46,530

56,400

35,250

56,400

164,500

133,245

115,150

54,285

65,800

41,125

65,800

188,000

152,280

131,600

62,040

75,200

47,000

75,200

3001-4000

916-1220

138,000

111,780

96,600

45,540

55,200

34,500

55,200

161,000

130,410

112,700

53,130

64,400

40,250

64,400

184,000

149,040

128,800

60,720

73,600

46,000

73,600

4001-5000

1221-1525

135,000

109,350

94,500

44,550

54,000

33,750

54,000

157,500

127,575

110,250

51,975

63,000

39,375

63,000

180,000

145,800

126,000

59,400

72,000

45,000

72,000

5001-6000

1526-1830

132,000

106,920

92,400

43,560

52,800

33,000

52,800

154,000

124,740

107,800

50,820

61,600

38,500

61,600

176,000

142,560

123,200

58,080

70,400

44,000

70,400

6001-7000

1831-2135

129,000

104,490

90,300

42,570

51,600

32,250

51,600

150,500

121,905

105,350

49,665

60,200

37,625

60,200

172,000

139,320

120,400

56,760

68,800

43,000

68,800

7001-8000

2136-2440

126,000

102,060

88,200

41,580

50,400

31,500

50,400

147,000

119,070

102,900

48,510

58,800

36,750

58,800

168,000

136,080

117,600

55,440

67,200

42,000

67,200

8001-9000

2441-2745

123,000

99,630

86,100

40,590

49,200

30,750

49,200

143,500

116,235

100,450

47,355

57,400

35,875

57,400

164,000

132,840

114,800

54,120

65,600

41,000

65,600