Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 31

Form I-PDH/SDH/PEH/SHH/PXH, Page 31

Overflow and Drain - All cooling modules are equipped with an overflow and drain

fitting. The fittings are in the cabinet bottom and come complete with a lock nut and

a sealing gasket. Check these fittings for tightness before installing the overflow and

drain piping. The drain and overflow fitting will accommodate 3/4” NPT fittings and are

also tapped with a 1/2” female pipe thread for iron pipe.

Bleed Off - If the module has a recirculating pump and float water control sys-

tem, it has a bleed off hose. The bleed off hose is attached to a tee in the fill line and

must drain into the overflow drain. Make sure that the end of the bleed off line extends

into the overflow drain. Adequate bleed off is important to maintaining an efficiently

operating system by lessening the concentration of undesirable minerals in the water

being circulated through the cooling module. Minerals buildup because evaporation

only releases “pure water vapor” causing the concentration of contaminants in the

water to increase as the evaporation process continues. The minerals accumulate on

the media, in the water lines, on the pump, and in the reservoir.

CAUTION: Water reservoir must be drained and pump motor

turned off when outside temperature falls below 32°F (0°C).

Pump must never be operated without water in the reservoir. See

Hazard Levels,page 2.

Water Hammer Arrestor - If the cooling module is equipped with an AquaSaver

timed metering system, the operation of the solenoid valve in the water line is con-

trolled by the timer. Due to various water pressures and installation conditions, the

water supply line may bang abruptly when the solenoid valve closes. This banging

can be minimized by installing an optional water hammer arrestor (Option ECB1) in

the supply line. When installing an optional water hammer arrestor, select an indoor

location (above 32°F), either horizontal or vertical, in line with and as close to the

solenoid valve as possible. Follow the manufacturer’s instructions to install and main-

tain the water hammer arrestor.

Recirculating Float and Pump Control System - Turn on the water supply and

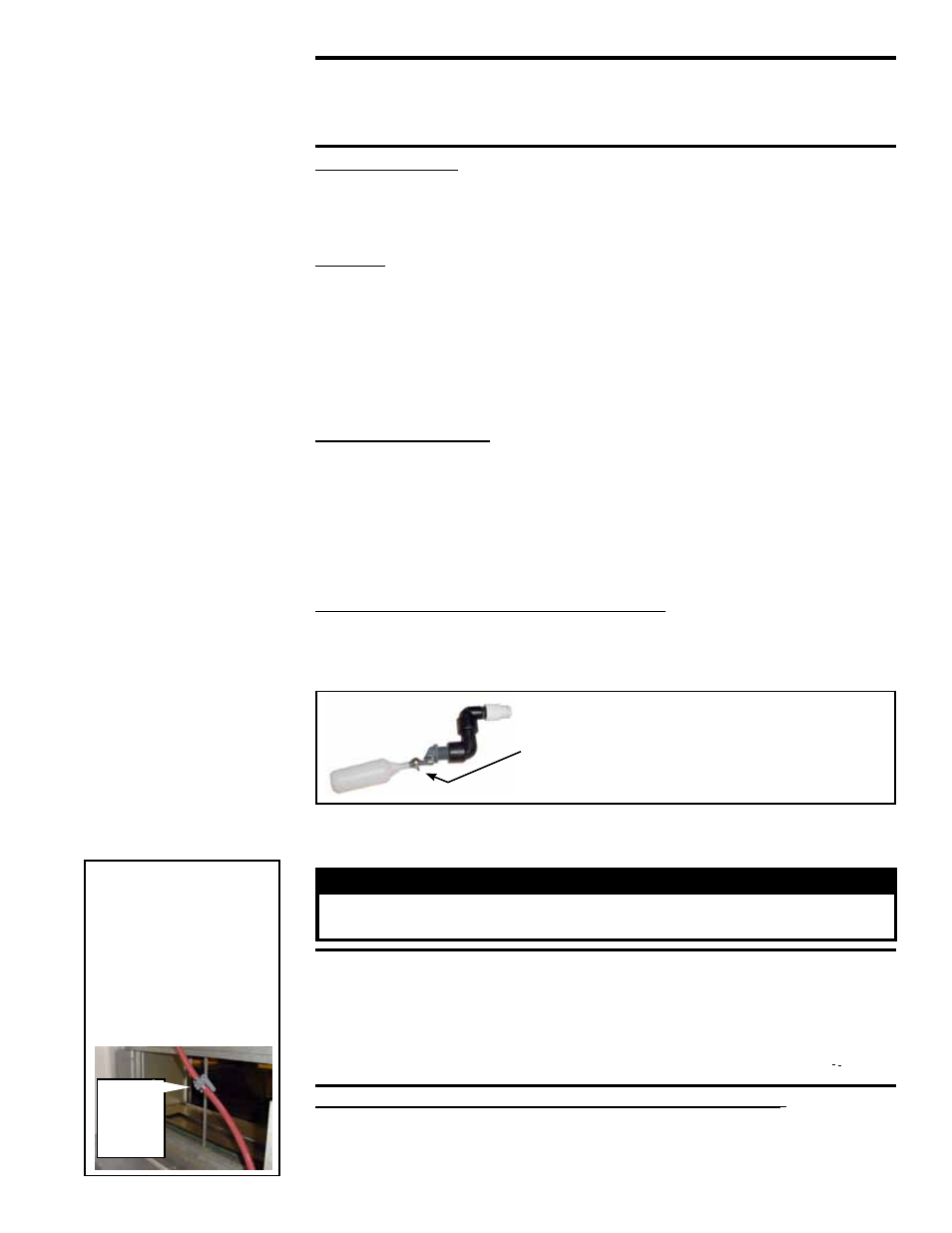

check for good flow. When the float valve (

FIGURE 23) shuts off the water supply,

measure the water depth. The depth of the water should be approximately 3” (76mm).

If necessary, adjust the position of the float valve with the wing nut to obtain the proper

water level.

Adjust the float valve position with the wing nut

to maintain approximately 3” (76mm) of water in

the reservoir

.

1/2” MPT Water Supply Connection

FIGURE 23 - Float

Valve, P/N 216553

6.5.2 Adjusting Water

Flow Over Pads

Proper water flow over the evaporative cooling media is critical to extend the life and

maintain the

efficiency of the pads. To adjust the flow, read the warnings and follow

the instructions that apply.

WARNING

Adjust ball valve only when the power is disconnected from the system.

Failure to do so can cause electrical shock, personal injury, or death.

CAUTION: Do not flood the media pads with extreme quantities of

water for long periods as this will cause premature breakdown of

the media. An even flow from top to bottom of the media with the

least amount of water is all that is required to assure maximum

efficiency and media life span. More water does not provide more

evaporation or more cooling.

Adjusting Water Flow with a Float and Pump Control System - Using the ball

valve, located in the length of hose running from the pump to the distribution line inlet

(See

FIGURE 24), adjust the valve handle to allow the flow to completely dampen the

media pads from top to bottom.

FIGURE 24 - Remove

side door and locate

ball valve (illustration

below is from the

rear). Both water flow

control systems have

a ball valve in the

water line.

Ball

Valve,

P/N

207468