0 mechanical (cont’d) – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 16

Form I-PDH/SDH/PEH/SHH/PXH, Page 16

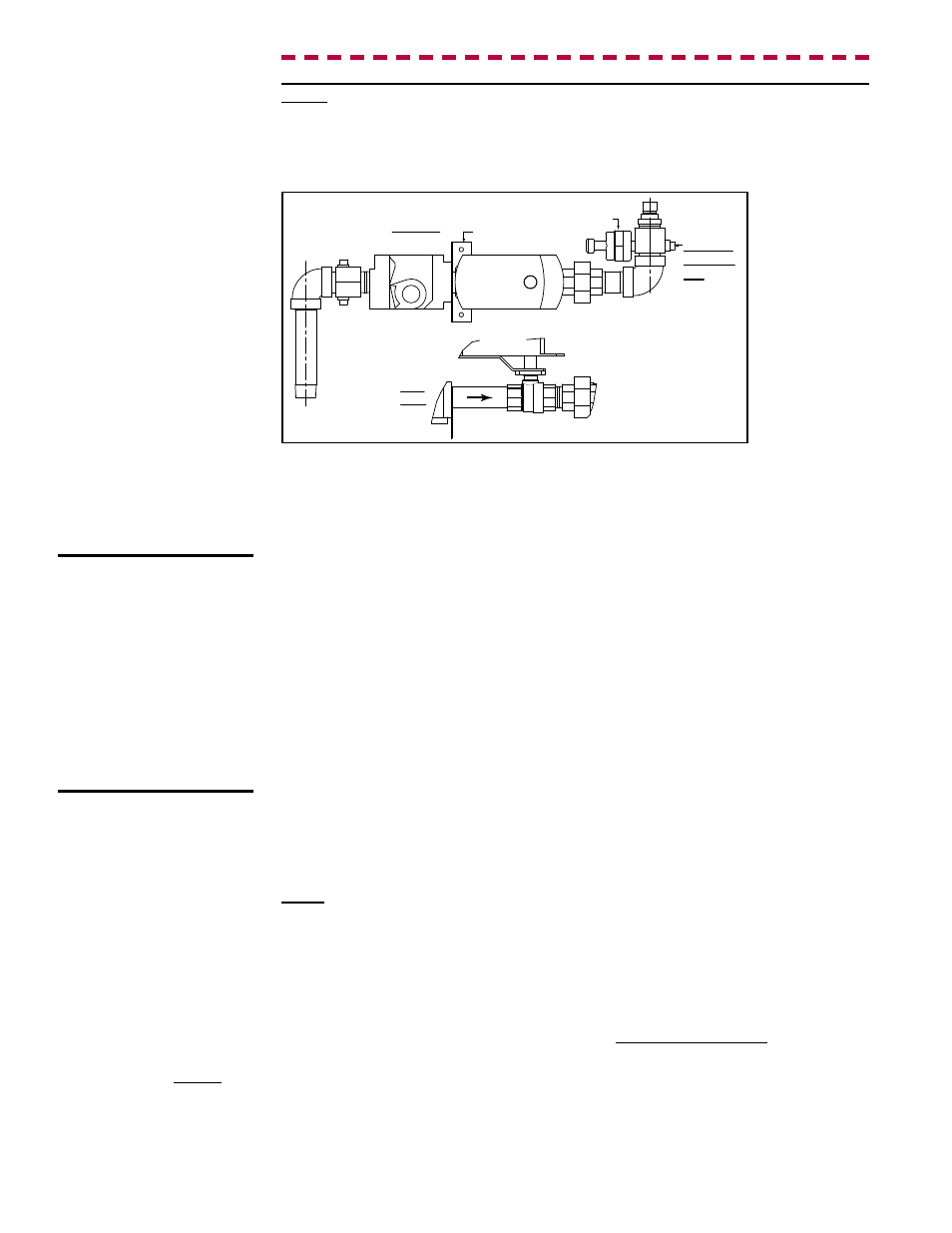

INSTRUCTIONS for ELECTRONIC MODULATION Gas Control Options AG58 and

D12G)

1) Measure the Manifold Pressure

Turn the manual valve in the gas line off.

Locate the manifold pressure tap; see

FIGURE 9. Remove the bushing and connect a

manometer to the 1/8" pressure tap.

Top View

Side

View

Ball Valve

Actuator

Ball Valve

Actuator

Combination

Single-Stage

Gas Valve

Pressure

Tranducer

Ball Valve

Gas Valve

Bracket

Orifice

Manifold

Pressure

Tap

FIGURE 9 - Gas

Manifold with Gas

Control Options AG58

and D12G

High Altitude Operation

If the heater is being installed at an elevation above 2000 ft (610M), check the rat-

ing plate to verify that the heater is factory-equipped for the elevation at the installation

site.

If the elevation on the rating plate matches the elevation of the installation

site, field adjustment for high altitude is not required.

If the rating plate does not match the elevation of the installation site, high altitude

adjustment will need to be done as part of the startup procedure. (High altitude adjust-

ment can only be done while the unit is operating.) During startup, follow the instruc-

tions in this section to adjust the valve outlet pressure.

Turn on the manual gas valve. Operate the unit with a call for heat. Verify that the

actuator has fully opened the ball valve (highest fire). The ball valve is fully open when

the dash marks on the actuator are aligned with the gas piping. With the burner at high-

est fire, measure the manifold pressure. The manifold pressure should be 3.4" w.c. for

natural gas or 10” w.c. for propane.

2) Adjust Pressure at the Single-Stage Valve (if needed)

Turn the manual gas valve off. On the single-stage gas valve (see FIGURE 6, page

14), locate the 1/8” output pressure tap and attach a manometer.

Turn on the manual gas valve. Operate the unit with a call for heat. Check the outlet

pressure of the valve with the burner at full fire. Pressure should be 3.5” w.c for natural

gas or 10” w.c. for propane.

If adjustment is necessary, remove the cap from the

adjustment screw. Set pressures to correct setting by turning the regulator screws IN

(clockwise) to increase pressure. Turn regulator screws OUT (counterclockwise) to

decrease pressure.

After an adjustment is made, cycle the heat section. Re-check the outlet pressure of

the valve and the manifold pressure. When pressure is correct for highest fire, remove

the manometers and replace the caps. Check for a leak at the pressure tap fittings.

3) Lowest fire manifold pressure is regulated by the ball valve actuator in response to

signals from the ignition control board. The ball valve was set at the factory and should

not need to be checked at startup. For future reference, instructions for checking low-

est fire pressure are in the operation/maintenance/service manual (

Form O-PREEVA

& SHH) included in the literature bag.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result

in unregulated

manifold pressure

causing excess

overfire and heat

exchanger failure.

NOTE: Modulating gas control Options AG58 and D12G DO NOT require a gas pres-

sure adjustment derate for high altitude. The patented control system works on a prin-

ciple of safe, continuous gas and combustion air monitoring and adjustment. As the

mass flow through the combustion system changes, due to the lower oxygen level at

high altitude, the control system senses the change, automatically reducing the firing

rate of the burner.

6.1.3 High Altitude

Operation - Gas-Fired

Model PDH, SDH, or

SHH being installed

above 2000 ft (610M)

(Adjustment does NOT

apply to Model SHH with

Gas Control Option AG58

or D12G -- see NOTE on

the right.)

6.0 Mechanical

(cont’d)

6.1 Gas Heat

Section Piping

and Pressure

- Models PDH,

SDH, and SHH

(cont’d)