0 mechanical (cont’d) – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 14

Form I-PDH/SDH/PEH/SHH/PXH, Page 14

6.1.2 Checking Gas Pressure

NOTE: If unsure of the

Gas Control Option Code

(AG1, AG2, AG3, AG8,

AG9, AG9H, AG15, AG16,

AG40, AG58, AG60, AG61,

AG62, DG1, DG2, DG5,

DG6, D12B, D12C, D12F,

or D12G), check the wiring

diagram on the heater.

All option codes affected

by electrical power are

listed on the bottom of the

wiring diagram after the

unit Model and Size.

Inlet Pressure (applies to all gas controls)

Before attempting to measure or adjust valve outlet gas pressure, the inlet (supply)

pressure must be within the specified range both when the heater is in operation and

on standby. Incorrect inlet (supply) pressure could cause excessive outlet gas pres-

sure immediately or at some future time. If natural gas inlet (supply) pressure is too

high, install a regulator in the supply line before it reaches the heater. If natural gas

supply pressure is too low, contact your gas supplier.

Inlet pressure to the valve for natural gas must be a minimum of 5” w.c. or as noted

on the rating plate and a maximum of 14” w.c. Inlet supply pressure to the valve for

propane gas must be a minimum of 11” w.c. and a maximum of 14” w.c.

Manifold Pressure at the Burner Orifice

Measuring manifold gas pressure cannot be done until the heater is in operation. It is

included in the “Check After Startup” steps, Paragraph 9.3. The procedure required

depends on the type of gas control option:

• Single and Two Stage Options

AG1, AG2, AG3, AG15, AG16, AG60, AG61,

AG62, DG1, DG5, D12C, D12F - Follow INSTRUCTIONS beginning below.

• Electronic Modulation (2:1 turndown) Options AG8, AG9, AG9H - Follow

instructions on page 15.

• Electronic Modulation (4:1 turndown) Options AG40, DG2, DG6, D12B -

Follow instructions on page 15.

• Electronic Modulation (8:1 turndown) Options AG58, D12G - Follow

instructions on page 16.

All gas pressure measurements should be done with a manometer (fluid-filled gauge)

rather than a spring type gauge due to the difficulty of maintaining calibration. Use a

water column manometer readable to the nearest tenth of an inch.

INSTRUCTIONS for single-stage and two-stage gas control options (Options

AG1, AG2, AG3, AG15, AG16, AG60, AG61, AG62, DG1, DG5, D12C, D12F)

The outlet pressure is regulated by the combination gas valve. The combination valve

outlet pressure should be as shown in

TABLE 10, page 17, (for the model size, gas

type, gas control option, and altitude of the installation) or as noted on the rating plate.

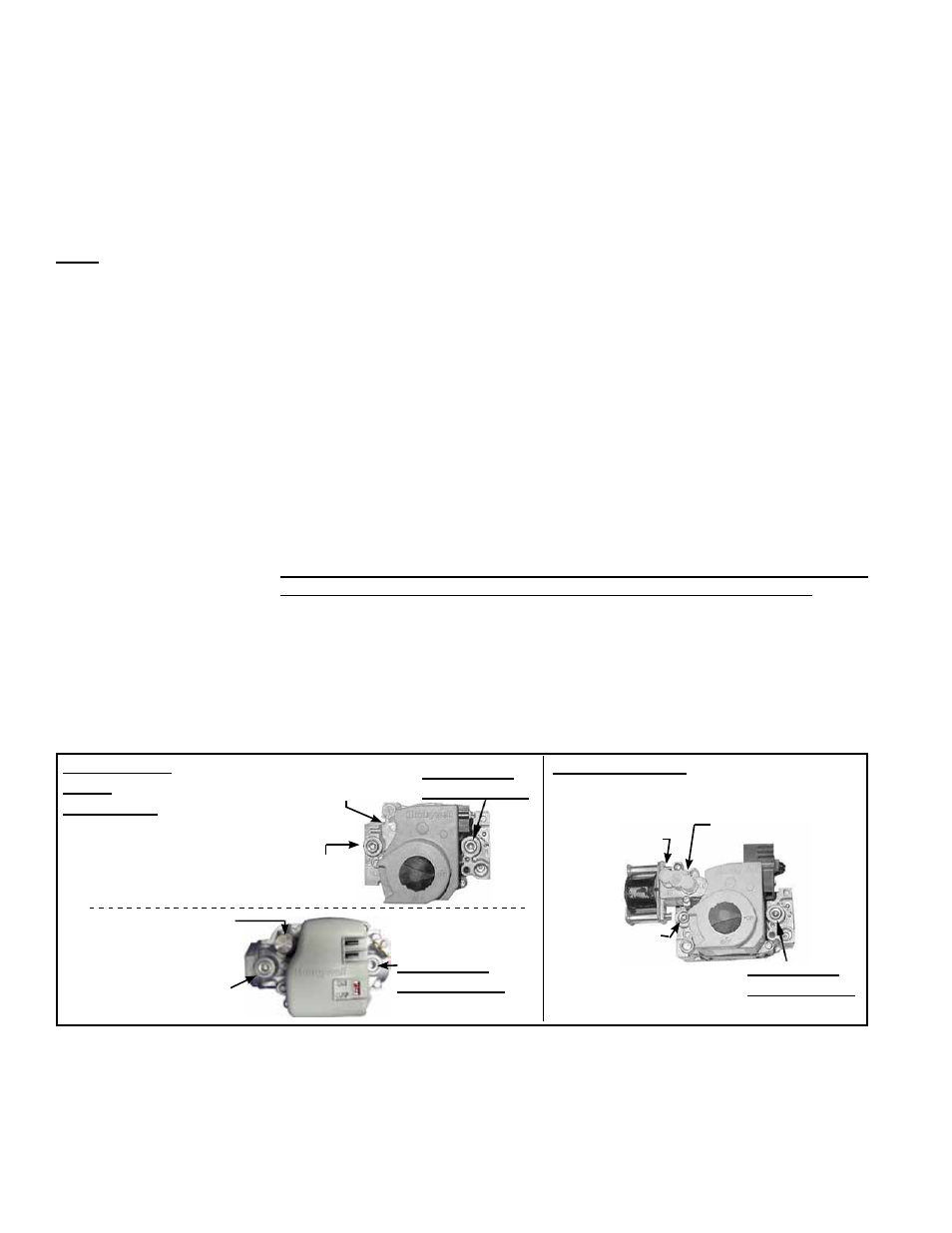

1) Gas Valve Pressure Tap Locations

Locate the 1/8” outlet pressure tap on the single or two-stage valve (See

FIGURE

6). With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” pipe outlet pressure tap in the valve. Both high-fire and low-

fire outlet pressure can be checked at this pressure tap.

2) Measure Outlet Pressure and Adjust (if needed)

Open the manual valve and operate the heater.

Using the manometer connected to the valve, measure the outlet pressure of the

single-stage gas valve or high fire on a two-stage valve. To measure low-stage

pressure on units equipped with a two-stage valve (Options AG2, AG3, AG15, AG16,

AG60, AG61, AG62, DG1, DG5, D12C, and D12F), disconnect the wire from the “HI”

terminal on the valve. Measure gas pressure with the manometer attached to the

valve. Re-connect the wire.

FIGURE 6 - Top Views

of Valves Showing

Outlet Pressure Tap and

Adjustment Locations

6.0 Mechanical

(cont’d)

6.1 Gas Heat

Section Piping

and Pressure

- Models PDH,

SDH, and SHH

(cont’d)

Single-Stage

Valve

(two styles)

1/8” Outlet

Pressure Tap

Adjust Outlet

Pressure

Inlet

Pressure Tap

Two-Stage Valve

Adjust High

Fire Outlet

Pressure

Adjust Low

Fire Outlet

Pressure

Inlet

Pressure

Tap

1/8” Outlet

Pressure Tap

1/8” Outlet

Pressure Tap

Inlet Pressure Tap

Adjust Outlet

Pressure