5 electrical operating components, 1 high temperature limit control - pdh, sdh, shh, Table 31 - pressure switch settings – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 47

Form I-PDH/SDH/PEH/SHH/PXH, Page 47

7.5 Electrical

Operating

Components

7.5.1 High Temperature Limit Control - PDH, SDH, SHH

Units are equipped with a temperature activated auto reset capillary-type limit control.

The control is factory set and is non-adjustable. If the setpoint is reached, the limit

control will interrupt the electric supply to the gas valve. This safety device provides

protection in the case of motor failure or lack of airflow due to a restriction at the inlet

or outlet.

CAUTION: The auto reset limit control will continue to shut down the heater until

the cause is corrected. Never bypass the limit control; hazardous conditions could

result. See Hazard Intensity Levels, page 2.

7.5.2 Reverse Airflow

Limit Control - PDH,

SDH, and SHH

Units are equipped with a temperature activated auto reset reverse airflow limit con-

trol. The control is factory set and is non-adjustable. If the setpoint is reached, the limit

control will interrupt the electric supply to the gas valve. This safety device provides

protection in the case of motor failure or lack of airflow due to a restriction at the outlet.

7.5.3 Combustion

Air Pressure Switch

(Air Proving Switch) -

PDH, SDH, and SHH

The combustion air proving switch is a pressure switch that monitors air pressure to

ensure that proper combustion airflow is available. On Model PDH, the switch is a

single pole/normally open device which closes when a negative pressure is sensed

in the venter housing. On separated-combustion Models SDH and SHH, the switch

senses the differential pressure between the negative pressure in the venter housing

and the pressure in the cabinet.

On startup when the heater is cold, the sensing pressure is at the most negative level,

and as the heater and flue system warm up, the sensing pressure becomes less nega-

tive. After the system has reached equilibrium (about 20 minutes), the sensing pres-

sure levels off.

If a restriction or excessive flue length or turns cause the sensing pressure to be out-

side the switch setpoint, the pressure switch will function to shutoff the main burner.

The main burner will remain off until the system has cooled and/or the flue system

resistance is reduced.

TABLE 31 lists the switch setpoints for sea level operating conditions by model and

size. The high speed settings apply to all units. The low speed settings apply only to

units with a two-speed venter (units with Gas Control Option AG8, AG9, AG9H, AG40,

AG60, AG61, AG62, DG1, DG2, DG5, DG6, D12B, D12C). Models equipped with two-

speed venter motor operation have two combustion air proving switches. When the

venter is operated at high speed, the “high speed” combustion air proving switch moni-

tors the combustion airflow to ensure adequate airflow for safe and efficient operation.

During low speed venter operation, when fuel gas input rate is reduced, a second

“low speed” combustion air proving switch monitors the combustion airflow to ensure

adequate airflow for safe and efficient operation.

NOTE: Above 6000 ft (1830

M) elevation, a high altitude

pressure switch may be

required. See Paragraph

6.1.3.

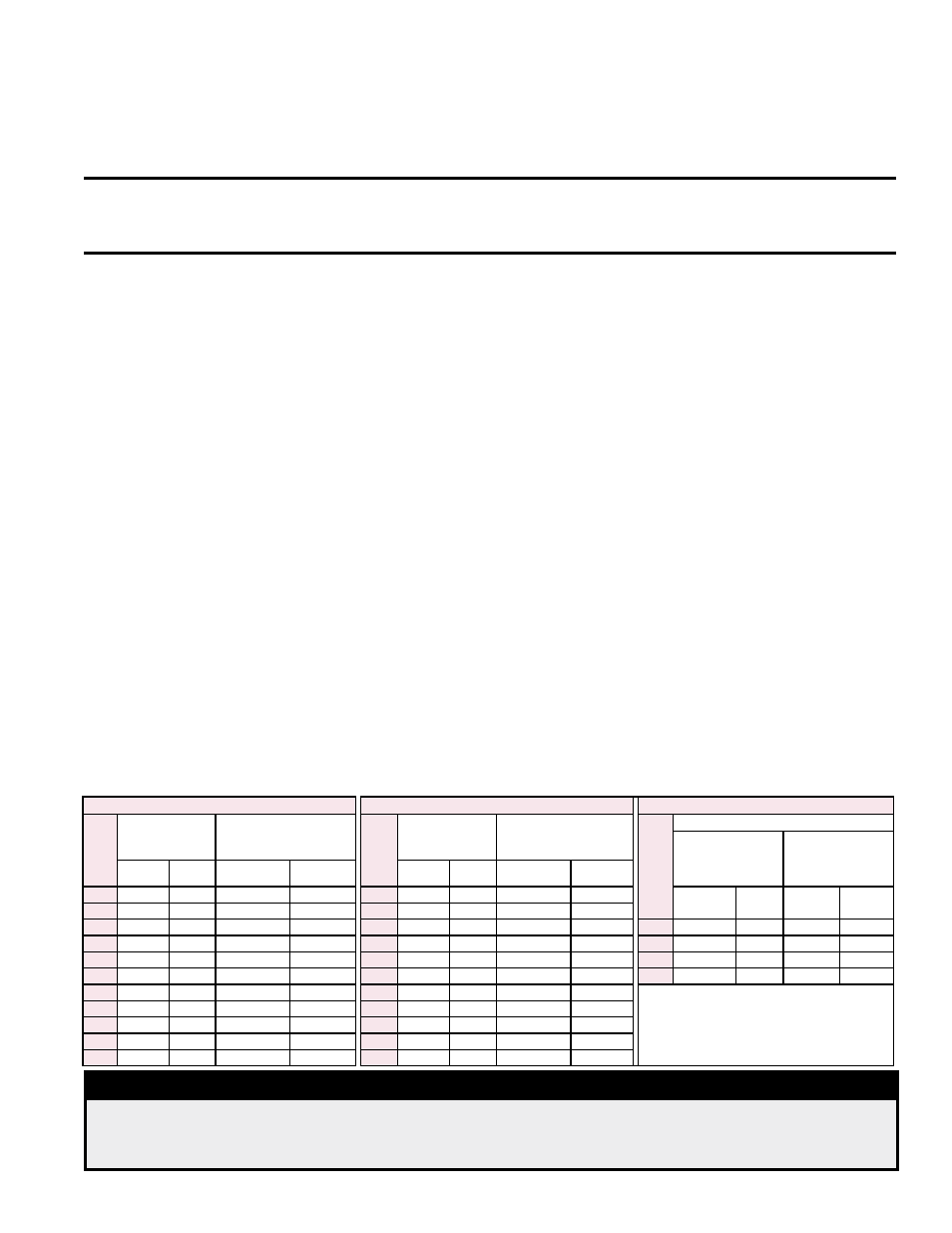

TABLE 31 - Pressure

Switch Settings

DANGER

Models PDH, SDH, and SHH require proper venting flow. NEVER bypass combustion air

proving switch(es) or attempt to operate the unit without the venter running and the proper

flow in the vent system. Hazardous conditions could result. See Hazard Levels, page 2.

P/N’s & Settings for Model PDH

P/N’s & Settings for Model SDH

P/N’s & Settings for Model SHH

PDH

Size

High Speed

(applies to all gas

controls)

Low Speed (applies only

to units with gas controls

using a 2-speed venter) *

SDH

Size

High Speed

(applies to all gas

controls)

Low Speed (applies only

to units with gas controls

using a 2-speed venter) *

SHH

Size

High Speed

Applies to SHH with

Options AG1, AG2,

AG3, AG15, AG16,

& D12F

Applies to SHH with

Option AG58 & D12G

Switch

P/N

Setting

(" w.c.)

Switch P/N

Setting

(" w.c.)

Switch

P/N

Setting

(" w.c.)

Switch P/N

Setting

(" w.c.)

75

197030

0.40

205442

0.20

75

197030

0.40

205442

0.20

Switch

P/N

Setting

(" w.c.)

Switch

P/N

Setting

(" w.c.)

100

197030

0.40

205444

0.30

100

197030

0.40

205444

0.30

125

196388

0.50

205444

0.30

125

196388

0.50

205444

0.30

130

201161

1.30

201160

1.05

150

197028

0.65

205444

0.30

150

197028

0.65

205444

0.30

180

201161

1.30

201160

1.05

175

201158

1.10

197030

0.40

175

201158

1.10

197030

0.40

260

201159

1.40

201160

1.05

200

201158

1.10

197030

0.40

200

201158

1.10

197030

0.40

350

221228

2.30

221160

1.05

225

201158

1.10

197030

0.40

225

201158

1.10

197030

0.40

* Gas Control Options AG8, AG9, AG9H,

AG40, AG60, AG61, AG62, DG1, DG2, DG5,

DG6, D12B, and D12C.

250

201158

1.10

197030

0.40

250

201158

1.10

197030

0.40

300

201158

1.10

197030

0.40

300

201158

1.10

197030

0.40

350

201158

1.10

197030

0.40

350

201158

1.10

197030

0.40

400A

201158

1.10

197030

0.40

400A

201158

1.10

197030

0.40