Checkline TI-CMXDLP User Manual

Page 49

– 49 –

Adjusting the B-Scan Speed (color version only)

The color version of the TI-CMXDLP has the

capability to adjust the scrolling speed of the time

based B-Scan displayed in the gauge. The procedures

to adjust the speed are outlined below:

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right, and the ESC key multiple times to

tab left,until the DISP menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until B-SCAN

SPEED is highlighted.

3. Use the LEFT and RIGHT arrow keys to scroll the speed from 0-10.

NOTE: 10 representing the fastest scroll time.

Once the appropriate speed is displayed, press the MEAS key to return to the

measurement screen and begin the B-Scan process.

4. Alternatively, press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7. Repeat steps 5 & 6 until the SPEED is correctly displayed.

8. Press the OK key to set the speed and return to the DISP menu., followed by

pressing the MEAS key to begin the B-Scan process.

9. Finally, press the MEAS key to return to the measurement screen and begin the

scanning process.

7.4 Gain

The gain, or ampliication of the return echoes, can be adjusted in the TI-CMXDLP

to accommodate a variety of applications. The setting of the gain is crucial in order to

obtain valid readings during the measurement process. Too much gain may result in

erroneous measurements, by detecting on noise rather than the actual material back wall

itself. Not enough gain may result in intermittent detection. It may also result in lack

of detection on internal laws, pits, or porosity. The gain can easily be compared to the

volume control of a home stereo system. If you turn it up too much, you can’t hear the

music clearly. If it’s turned down too much, you can’t hear it.

– 56 –

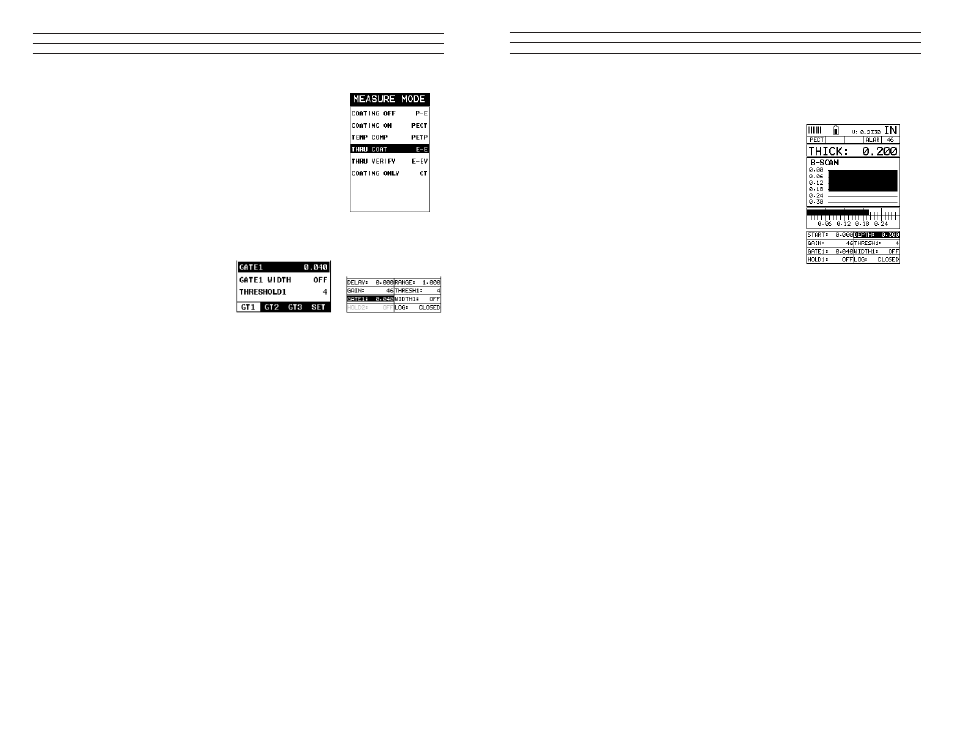

Activating the gates:·

Automatically:

The gates are automatically activated, when a measurement

mode is selected. Gate1 is active in all measurement modes.

These modes have been internally setup at the factory.

Therefore, if the user selects the Thru Coat (E-E) option, an

internal setup will be loaded, and 2 gates will automatically

be activated. This setup will work ine for the majority of all

common applications. The user has the ability to ine adjust

the gates settings, which will be further explained in the

sections that follow.·

Manually:

The gates can also be activated

manually by using the Hot or Tabbed

menus. For example: If any of

the pulse echo modes (PE, PECT,

PETP), shown in diagram 1, have

been selected, only gate 1 will have

been activated from the factory

setup. However, the user may have

a requirement to activate and utilize

more than one gate, depending on the application.

7.7 Gates

The TI-CMXDLP is equipped with 3 gates, as explained in the previous section. One

gate is active at all times in every measurement mode, with the exception of coating

mode. These gates are full featured and completely adjustable. They can be ine tuned

by the user to accommodate a variety of application scenarios. Diagram 1 in the

previous section outlines the gates and features available for all measurement modes.

Refer to the previous section for additional information. These features are described in

more detail below:

NOTE: In order to adjust the gates they must be activated. The gates are automatically

activated depending upon the measurement mode selected. If a gate is inactive, it will

be grayed out in the hot and tabbed menus. The explanations thatfollow, assume that the

proper measurement mode has been selected. Refer to section 5.2 for more information

on selecting measurement modes.

Gate 1

Is used in all measurement modes, and has the following features assigned to it;start,

width, and threshold. A gate can be used to overcome a great deal of application

scenarios. Surface noise, for instance, close to the initial pulse can cause the erroneous

measurements as the transducer receives relections from the noise. By adjusting the

start position of the gate, the noise can be blocked and eliminated. This is typical in

Tabbed Menu

Hot Menu