Checkline TI-CMXDLP User Manual

Page 48

– 48 –

Adjusting the Range (B-Depth)

Once again, just to reiterate, the Range (B-Depth) + Delay (B-Start) equals the right

side of the screen. Therefore, the Range (B-Depth) is the overall area, from the delay,

that will be viewable on the screen. The TI-CMXDLP digitizer will round up from the

Range (B-Depth) that’s entered. Therefore, if the Range (B-Depth) is set at 1.0”, the

digitizer will round this value up to the next adjustment available. The procedures to

adjust the overall thickness range viewed Range (B-Depth) are outlined below:

1. Press the MEAS key once to

activate measure menu items.

Press the MEAS key multiple

times to move right and the

ESC key multiple times to move

left, until the WIDTH cell is

highlighted.

2. Press the UP, DOWN, LEFT,

and RIGHT arrow keys to scroll

the highlighted value.

3. Alternatively , press the ENTER

key to display the Digits Edit

Box.

4. Press the UP and DOWN arrow

keys to scroll the highlighted

value.

5. Press the LEFT and RIGHT

arrow keys to scroll the digit

locations.

6. Repeat steps 4 & 5 until the

WIDTH value is correctly

displayed.

7. Press the OK key to return to the

measurement screen, or ESC to

cancel entering the WIDTH.

8. Finally, press the MEAS key to

return to the measurement screen

and begin taking readings.

– 57 –

aluminum, stainless steel, and titanium. This can also be a function of using a low

frequency transducer, which are known to be inherently noisy off the initial pulse. The

start feature of the gate is also used in multiple echo modes to control measurements

between 2 or more echoes. As we saw in previous section,the threshold can be used

to control the sensitivity level, and used in combination with the width, control the

sensitivity over a speciic range.

Gate 2 & 3

These gate options will most commonly be used for multiple echo measurement modes,

to measure between 2 or more echoes ( E-E and E-EV). They are also handy to use in

a stand pulse echo mode, to create a pseudo time corrected gain feel. As the thickness

of the material increases, the signal amplitude of the relection decreases. Why not just

turn up the gain? Well, this is certainly something to consider, but is not always the

best answer. As the gain is increased, the noise level is also increased. At some point,

increasing the gain provides little or no beneit to the quality of the signal, and the

additional noise introduced makes things worse. By activating another gate, optimizing

the gain level, setting the thresholds, and adjusting the widths of the gates to cover

speciic thickness ranges, a tough application might not be so bad after all. These gates

have the following features set assigned to them; holdoff (delay), width, and threshold.

Noise

Blocked

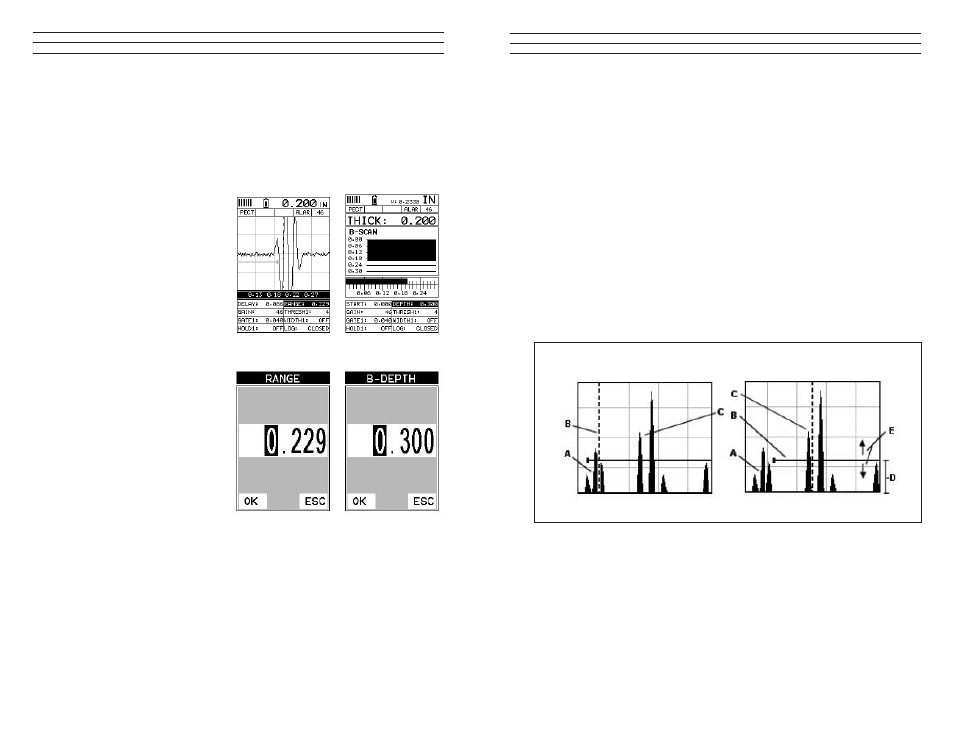

Example of Surface or Transducer Noise

The diagrams above illustrate a typical surface noise condition. Refer to the Noise

diagram: (A) refers to the noise in front of the actual back wall signal (C). Notice the

start position of the gate. As a result, the TI-CMXDLP is detecting on the noise (A) as

shown at point (B). However, the true measurement should be taken at point (C). Given

the start, threshold, and gain levels, the amplitude from the noise is suficient enough

to cause the TI-CMXDLP to detect, or measure the noise rather than the true back wall

thickness.

Now refer to the Blocked diagram. The horizontal line at the top of (D), is GATE1. The

start of GATE1 has been moved just beyond the noise (A) to block the noise and detect

on the correct signal (C). Note: the TI-CMXDLP will only detect on signals that are