Checkline TI-CMXDLP User Manual

Page 12

– 12 –

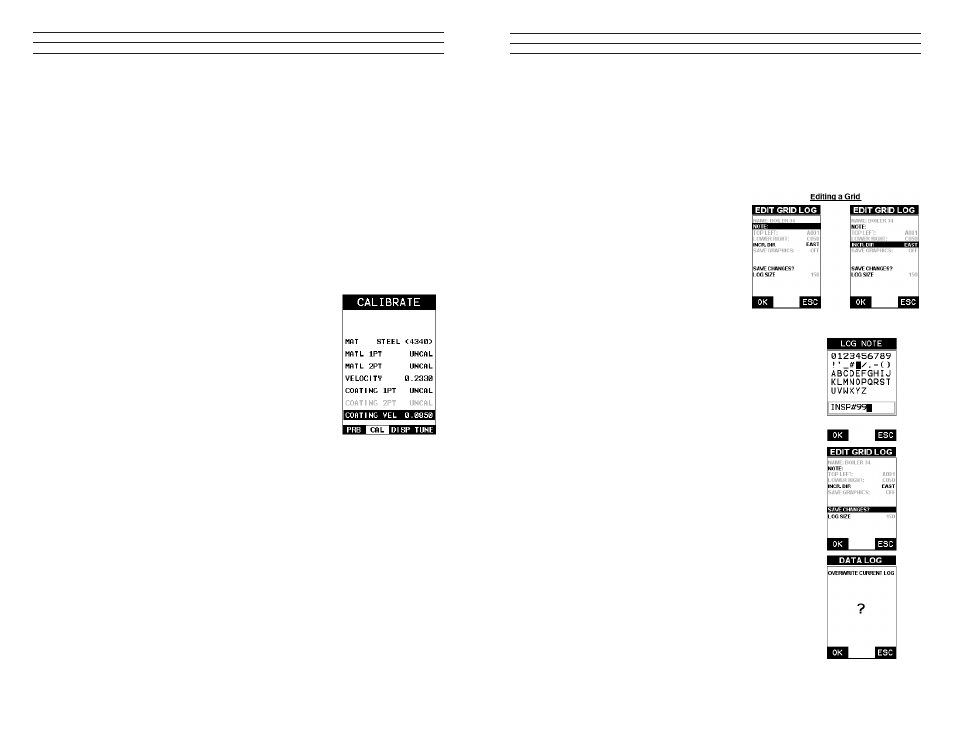

2.6 Coating Calibration

The TI-CMXDLP has been preset to a default coating velocity of 0.0850 in/μsec

(2159m/sec). This will be very close to the most common coating material velocities

used in the ield. If the velocity of the coating is known, and different than the above

default setting, the user can simply enter the coating velocity into the TI-CMXDLP.

However, if the velocity is unknown, the TI-CMXDLP can also be calibrated to a

speciic coating sample/type using the 1pt calibration option in PECT (pulse-echo

coating)mode, or a two point calibration is CT (coating only) mode. For the purpose

of this quick start section only the 1pt option PECT (pulse-echo coating) mode will

be covered. Refer to the calibration section of the manual for a complete explanation

on the coating calibration options. The following steps below outline the necessary

steps to either set the velocity of the coating, or perform a one point calibration to

calculate the coating velocity:

Known Coating Velocity

If the coating velocity is known, the user may wish to

simply enter the velocity number into the TI-CMXDLP,

rather than have the TI-CMXDLP calculate the velocity

value using a known thickness on a coating sample. The

steps for entering the velocity are outlined below:

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right and

the ESC key multiple times to tab left until the CAL

menu is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until COATING VEL is highlighted.

3. Press the ENTER key to display the Digits Edit Box.

4. Press the UP and DOWN arrow keys to scroll the

highlighted value.

5. Press the LEFT and RIGHT arrow keys to scroll the

digit locations.

6. Repeat steps 4 & 5 until the velocity number is correctly

displayed.

7. Press the OK key to set the coating velocity and return

to the menu screen,or ESC to cancel entering the

coating velocity.

8. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

– 93 –

4. Press the OK key to delete All Files from memory, or the ESC key to abort.

5. Press the MEAS key to return to the measurement screen.

11.6 Editing a Grid (File)

Once a grid has been created and saved to memory, the user can edit the Comments or

Increment Direction at a later time. The following procedures outline this process

1. Press the MENU key once to activate

the menu items tab. Press the MENU

key multiple times to tab right and the

ESC key multiple times to tab left until

the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to

scroll through the sub menu items until

EDIT is highlighted.

3. Press the ENTER key to display the Edit List Box.

4. Use the UP and DOWN arrow keys to scroll through

the Edit options until NOTE or INCR. DIR is

highlighted.

NOTE: If editing the INCR. DIR, simply use the LEFT

or RIGHT arrow keys to scroll NONE, NORTH, EAST,

SOUTH, WEST for a Grid, or INC, DEC for a SeqLog.

Proceed to step 10.

5. Press the ENTER key to activate the Alpha Edit box –

Only used when editing the NOTE.

6. Use the UP, DOWN, LEFT, & RIGHT arrow keys to

highlight the appropriate alpha characters.

7. Press the ENTER key to select a character and

advance to the next ield of the Comments.

8. Use the CLR key to backspace if necessary.

9. Repeat steps 6 - 8 until the Comments are completed

10. Press the UP or DOWN arrow key to highlight

SAVE CHANGES, and the OK key to activate the

conirmation screen.

11. Press the OK key to save the changes or the ESC key

to cancel editing the ile parameters.

12. Press the MEAS key to return to the measurement screen.