Checkline FGS-100H User Manual

Check, Line, Instruction manual

Instruction Manual

Instruction Manual

Instruction Manual

Instruction Manual

Instruction Manual

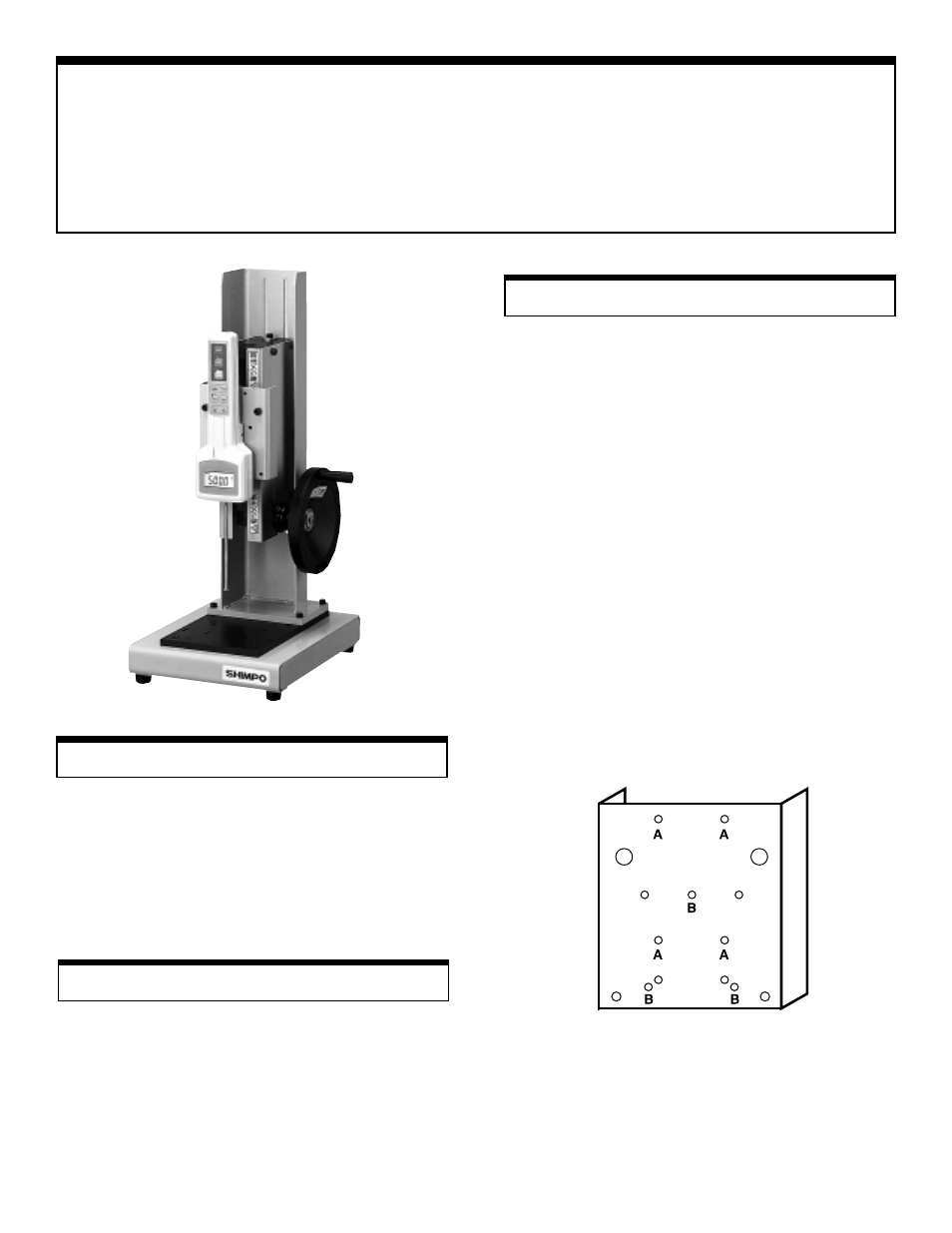

Manual Hand Wheel

Test Stand

Model FGS-100H / FGS-50H

Specifications

Accessories

Mounting Bracket

Capacity:

50Kg (110lbs.)

Travel:

150mm (5.9in.) MAX

Clearance:

50-202mm

6 positions, 30mm/step (5 steps)

Weight:

15Kg (33lbs.)

Force Gauges

1. Remove the bracket from the test stand using the 5mm

Allen wrench included.

2. Use the mounting holes marked “A” on the diagram for

mounting the FGE and FGV series force gauges with the

(4) M4x8 Philips head screws included.

3. Use the mounting holes marked “B” on the diagram for

mounting the DFS series force gauges with the (3)

M5x6 Philips head screws included.

4. Adjust the clearance span by removing the hex bolt from

the hole in the back of the stand. Loosen but do not

remove the hex bolts from the (3) slots. Adjust the span

by sliding the drive unit to the hole position desired and

insert the hex bolt and tighten. Tighten the (3) hex bolts

in the slots as well.

5. Re-install the bracket with the force gauge to the test stand.

6. Testing may now begin with the force gauge and test stand.

Mounting bracket ................................... 1pc.

Cable holder ........................................... 1pc.

5mm Allen wrench ................................. 1pc.

Philips head screw M4x8 ...................... 4pcs.

Philips head screw M5x6 ...................... 3pcs.

Mounting Bracket

CHECK

•

LINE

®