Checkline TI-CMXDLP User Manual

Page 13

– 13 –

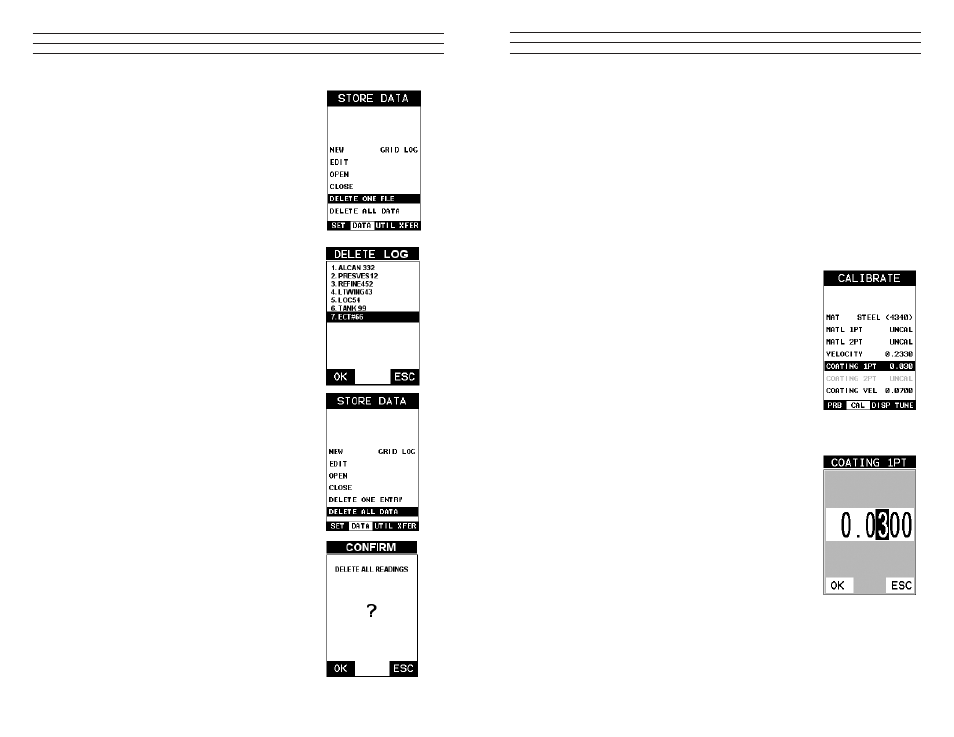

Known Coating Thickness

When the exact velocity of a coating is unknown, the user has the option of performing

a one point calibration on a sample of the coating with a known thickness to determine

the sound velocity. It would be very handy to carry a set of mechanical calipers to use in

conjunction with the TI-CMXDLP for calibration in the ield:

1. Physically measure a location on a coating sample using a set of calipers or a digital

micrometer.

IMPORTANT NOTE: In PECT (pulse-echo coating) mode, the coating sample must be

coupled to metal in order to calibrate successfully. Simply place a drop of couplant on

a piece of metal, lay the coating sample over the couplant on the metal and proceed to

step 2.

2. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the coating (on metal)

sample or actual test material. Be sure that the reading is

stable and the repeatability indicator, in the top left corner

of the display, is fully lit and stable. Press the MENU

key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple

times to tab left until the CAL menu is highlighted and

displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the

sub menu items until COATING 1PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctly displayed.

8. Press the OK key to calculate the coating velocity and

return to the menu screen, or ESC to cancel the one point

calibration.

9. Finally, press the MEAS key to return to the measurement

screen and begin taking readings.

NOTE: CHECK YOUR CALIBRATION! Place the transducer back on the calibration

point. The coating thickness reading should now match the known coating thickness

sample. If the thickness is not correct, repeat the steps above.

– 92 –

4. The user may opt to clear a speciic reading

and save a new one at anytime. Press the CLR

key in the appropriate cell location to clear the

reading,take a new measurement, and press the

ENTER key to save the new reading.

5. Abort the Grid/Seq Log View Box by pressing

the MEAS key at any time.

11.5 Deleting Grids (Files)

Deleting One File

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right and the ESC key multiple times to

tab left until the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until DELETE ONE

FILE is highlighted.

3. Press the ENTER key to display the File List

Box.

4. Use the UP and DOWN arrow keys to scroll

through the stored Files until the target File to

delete is highlighted.

5. Press the OK key to delete the File.

6. Press the MEAS key to return to the

measurement screen.

Deleting All Data

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right and the ESC key multiple times to

tab left until the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until DELETE ALL

DATA is highlighted.

3. Press the ENTER key to activate the

conirmation screen.