Checkline TI-CMXDLP User Manual

Page 36

– 36 –

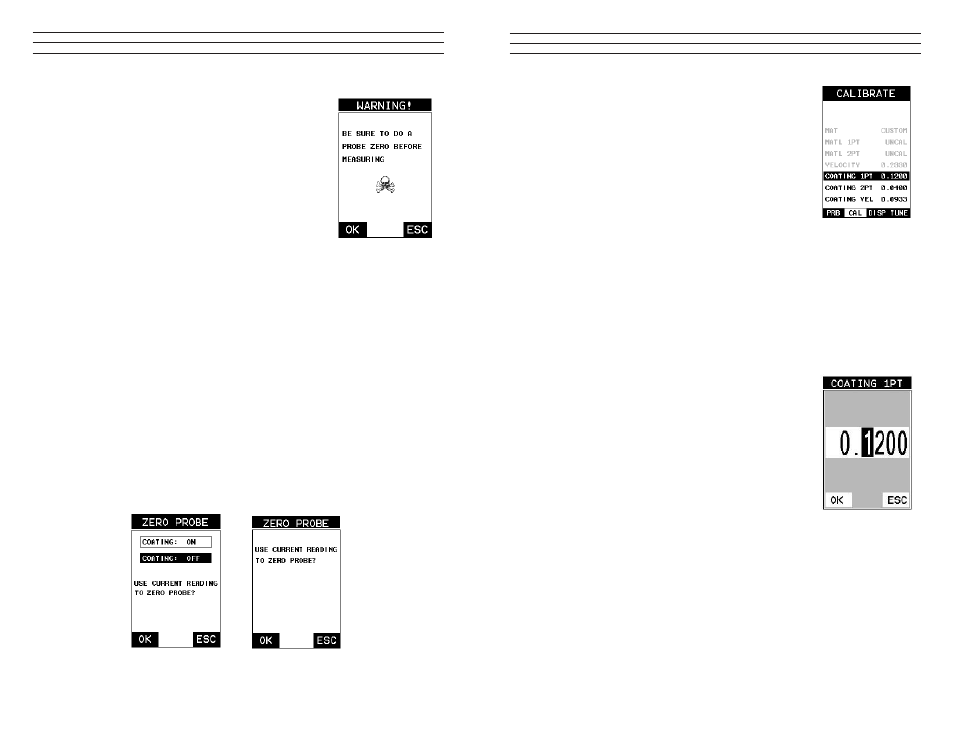

Coating Probe

Identified

Coating Probe

Not Identified

Performing a Manual Probe Zero (On Block)

NOTE: When the zero probe option is set to manual, the

Probe Zero Disk(battery cap) located on the top of the

gauge will be used as a zero standard and the warning

screen illustrated above will be displayed.

1. Press the OK or ESC keys to enter the main

measurement screen and begin the manual zero process.

2. Apply a drop of couplant on the transducer and place

the transducer in steady contact with the Probe Zero

Disk and obtain a steady reading.

3. Press the MENU key once to activate the menu items tab. Press the MENU key

multiple times to tab right and the ESC key multiple times to tab left until the PRB

menu is highlighted and displaying the submenu items.

4. Press the UP and DOWN arrow keys to scroll through the sub menu items until

ZERO PROBE is highlighted.

5. Press the ENTER key to display the conirmation screen.

6. If a coating transducer was identiied use the UP and DOWN arrow keys to toggle

coating on/off.

7. Press the OK key to complete the probe zero function, or ESC key to cancel the

probe zero function.

8. Remove the transducer from the Probe Zero Disk, and proceed to the calibration

section.

NOTE: The value that is displayed will change depending on the current velocity

setting. Disregard the number that is displayed. It is not important. What is important

is accurately performing the steps outlined above to insure reliability of the probe zero

calculation.

–69 –

One Point Calibration

NOTE: Use the maximum coating sample for the one point

calibration irst.

1. Physically measure the thicker of the two samples of

coating, as close as possible to the maximum expected

coating measurement range, using a set of calipers or a

digital micrometer.

VERY IMPORTANT: If coating measurements will be

made with the coating applied to a metal surface, the

calibration must be done in the same manner,with the

samples coupled to a metal surface. However, if the coating

will be measured as a stand alone material, the calibration

must be performed the same way.

2. Apply a drop of couplant on the transducer and place the transducer in steady

contact with the thicker of the two coating and samples ist. Be sure that the reading

is stable and the repeatability indicator, in the top left corner of the display, is fully

lit and stable. Press the MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right and the ESC key multiple times to tab left

until the CAL menu is highlighted and displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the

sub menu items until COATING 1PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the

digit locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctly displayed.

8. Press the OK key to calculate the velocity and return to

the menu screen, or ESC to cancel the coating one point

calibration.

9. Finally, press the MEAS key to return to the

measurement screen and begin taking readings