Checkline TI-CMXDLP User Manual

Page 38

– 38 –

range is .100” (2.54mm) to 1.0” (25.4mm), the user should calibrate on a known

thickness sample close to 1.0” (25.4mm).

NOTE: It’s always handy to carry a set of mechanical calipers to use in conjunction

with the TI-CMXDLP for calibration in the ield.

One Point Calibration

NOTE: Be sure that the probe zero procedure has been performed prior to performing

this calibration procedure.

1. Physically measure an exact sample of the material or a location directly on the

material to be measured using a set of calipers or a digital micrometer.

2. Apply a drop of couplant on the transducer and place the transducer in steady

contact with the sample or actual test material. Be sure that the reading is stable

and the repeatability indicator, in the top left corner

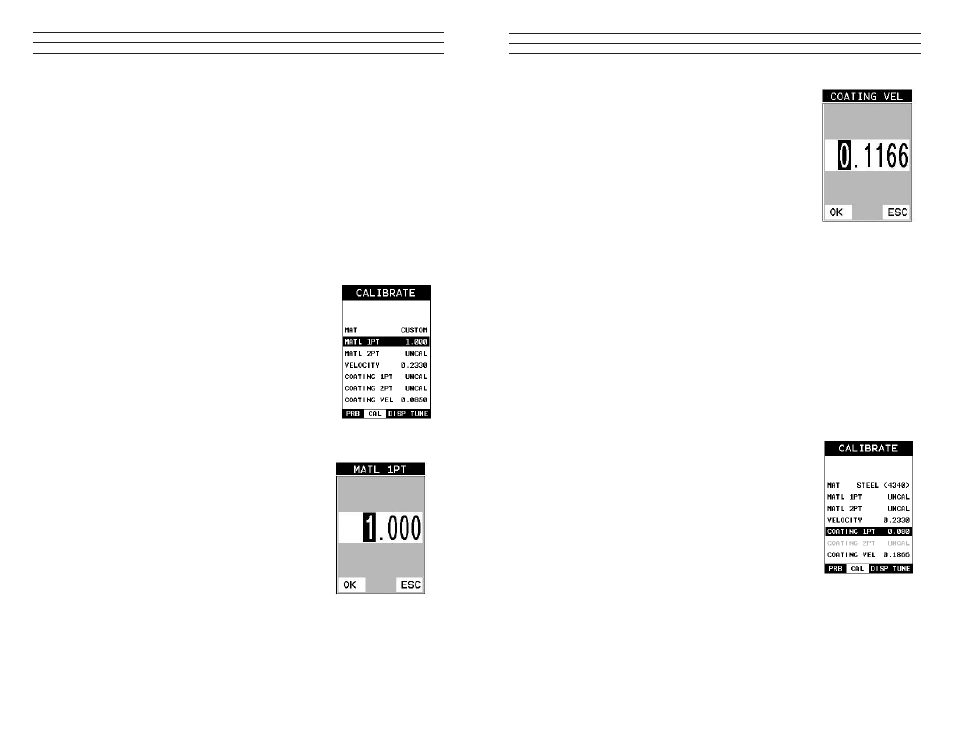

of the display, is fully lit and stable. Press the MENU

key once to activate the menu items tab. Press the

MENU key multiple times to tab right and the ESC

key multiple times to tab left until the CAL menu is

highlighted and displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through

the sub menu items until MATL 1PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the

digit locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctly displayed.

8. Press the OK key to calculate the velocity and return

to the menu screen, or ESC to cancel the one point

calibration.

9. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

NOTE: CHECK YOUR CALIBRATION! Place the

transducer back on the calibration point. The thickness reading should now match the

known thickness. If the thickness is not correct, repeat the steps above.

– 67 –

6. Repeat steps 4 & 5 until the velocity number is correctly

displayed.

7. Press the OK key to set the velocity and return to the

menu screen, or ESC to cancel entering the velocity.

8. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

Known Thickness

Sometimes the sound velocity of a coating material is

unknown. In this case a sample with a known thickness can

be used to determine the sound velocity of the coating. As previously discussed, the

TI-CMXDLP offers a one point calibration option for coating in PECT measurement

mode. It is also import to reiterate that the coating sample must be coupled to a metallic

material in order to perform the calibration. The calibration should also consider

calibrating on high side of the intended measurement range, when using the one point

option, minimize overall error. For example, if the measurement range of the coating

will be from .040” - .080” (1.0mm – 2.3mm), a coating closest to .080 (2.0mm)

should be used. Note: It’s always handy to carry a set of mechanical calipers to use in

conjunction with the TI-CMXDLP for calibration in the ield:

One Point Calibration

NOTE: Be sure that the probe zero procedure has been performed prior to performing

this calibration procedure.

1. Physically measure an exact sample of the coating using a set of calipers or a digital

micrometer.

NOTE: The coating sample must be coupled to a metallic

material in order to be calibrated.

2. Apply a drop of couplant on a piece of metal and place

the coating sample on the metal over the couplant. Apply a

drop of couplant on the transducer and place the transducer

in steady contact with the coating and sample or actual

test material. Be sure that the reading is stable and the

repeatability indicator, in the top left corner of the display,

is fully lit and stable. Press the MENU key once to activate

the menu items tab. Press the MENU key multiple times to

tab right and the ESC key multiple times to tab left until the

CAL menu is highlighted and displaying the submenu items.