Checkline TI-CMXDLP User Manual

Page 31

– 31 –

measured without having to remove the coating prior to measuring. Users will often use

pulse echo mode and echo-echo mode in conjunction when performing inspections on

coated materials.

Thru coating measurements require special high damped transducers. The most common

transducers are the 3.5, 5, and 7.5 MHz hi-damped transducers. These transducers are

suitable for use in both pulse-echo and echo-echo modes. This conveniently enables the

user to accurately measure overall material thickness using the thru Coating mode, and

then conveniently switch to pit detection mode without changing transducers. The ¼”

5 MHz hi-damped transducer is the most commonly used transducer for standard thru

coating applications.

Coating Only

The coating only mode should be used when the application calls for coating

measurements only and the user is not interested in the thickness of the material the

coating has been applied to. This mode can also be used as a stand alone coating

thickness gauge, where the coating has not been applied to another material surface. An

auto identiied coating probe must be attached to the TI-CMXDLP in order to enable

this mode.

Thin materials

Use pulse echo mode and a high frequency transducer for these types of applications.

The most common transducers are the 7.5 MHz and 10 MHz models with extra

resolution. The higher frequencies provide greater resolution and a lower minimum

thickness rating overall.

High temperature

Use and select a special 2.25 MHz and 5 MHz High temperature transducer for these

types of applications. Both pulse-echo and echo-echo modes will also work for these

applications. However, echo-echo mode will eliminate error caused by temperature

variations in the delay line of the transducer.

Noisy Material

Materials such as titanium, stainless steel, and aluminum may have inherent surface

noise issues. This is a signal that appears at the surface of the material when using a

dual element delay line probe. Select a higher frequency transducer to reduce this

oise – 7.5 MHz and higher for better resolution.

Restricted access

Measuring materials with extreme curvatures or restricted access, higher frequencies

with smaller diameters should be considered. The smallest diameter uses 3/16”crystals

with a contact area of .250”. Custom transducers are available on request.

– 74 –

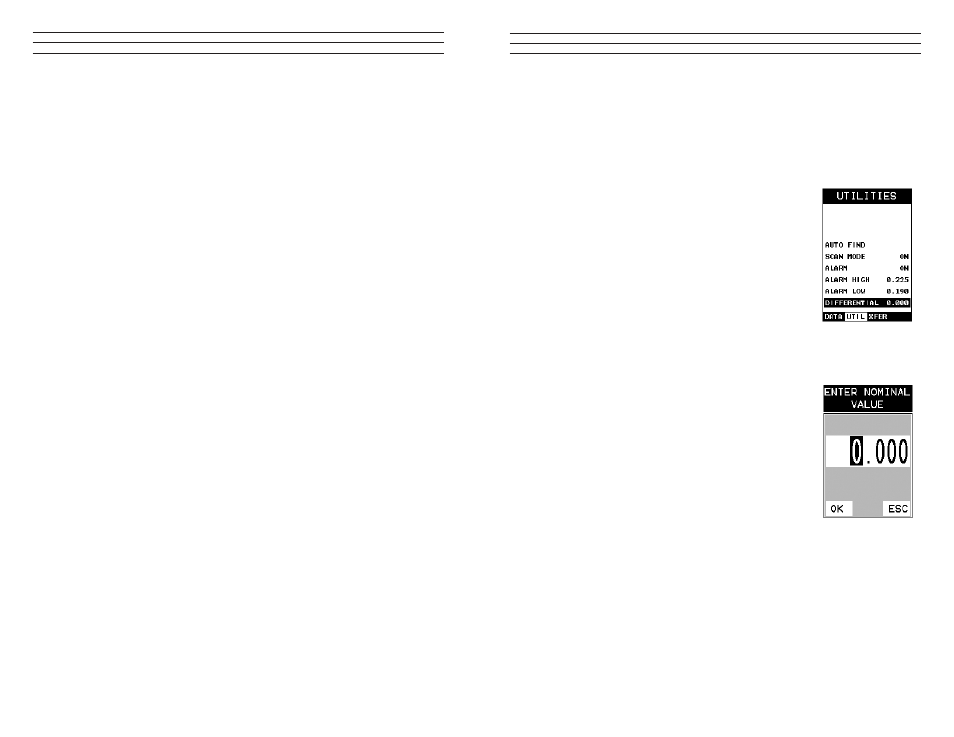

10.4 Differential Mode

The Differential Mode of the TI-CMXDLP provides the user with the ability to set

a nominal value, according to what the expected thickness should be, and measure

the+/- difference from the nominal value entered. This feature is typically used in QA,

incoming inspections on pipes, plate stock, coils, etc. The steps below outline how to

enable and enter the nominal value to use this feature:

Toggle Differential Off

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right, and

the ESC key multiple times to tab left, until the UTIL

menu is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until DIFFERENTIAL is highlighted.

3. Use the LEFT and RIGHT arrow keys to toggle the

DIFFERENTIAL on. A value will appear to the right of

DIFFERENTIAL.

4. Continue on to the next section “Setting the Differential Value”.

Setting the Differential Value

1. Assuming DIFFERENTIAL has been enabled

and a value is being displayed to the right of the

DIFFERENTIAL label, press the ENTER key to display

the Digits Edit Box.

2. Press the UP and DOWN arrow keys to scroll the

highlighted value.

3. Press the LEFT and RIGHT arrow keys to scroll

the digit locations.

4. Repeat steps 2 & 3 until the DIFFERENTIAL value

is correctly displayed.

5. Press the OK key to set the DIFFERENTIAL value

and return to the menu screen.

6. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.