Checkline FGS-250W User Manual

Checkline Sensors

z

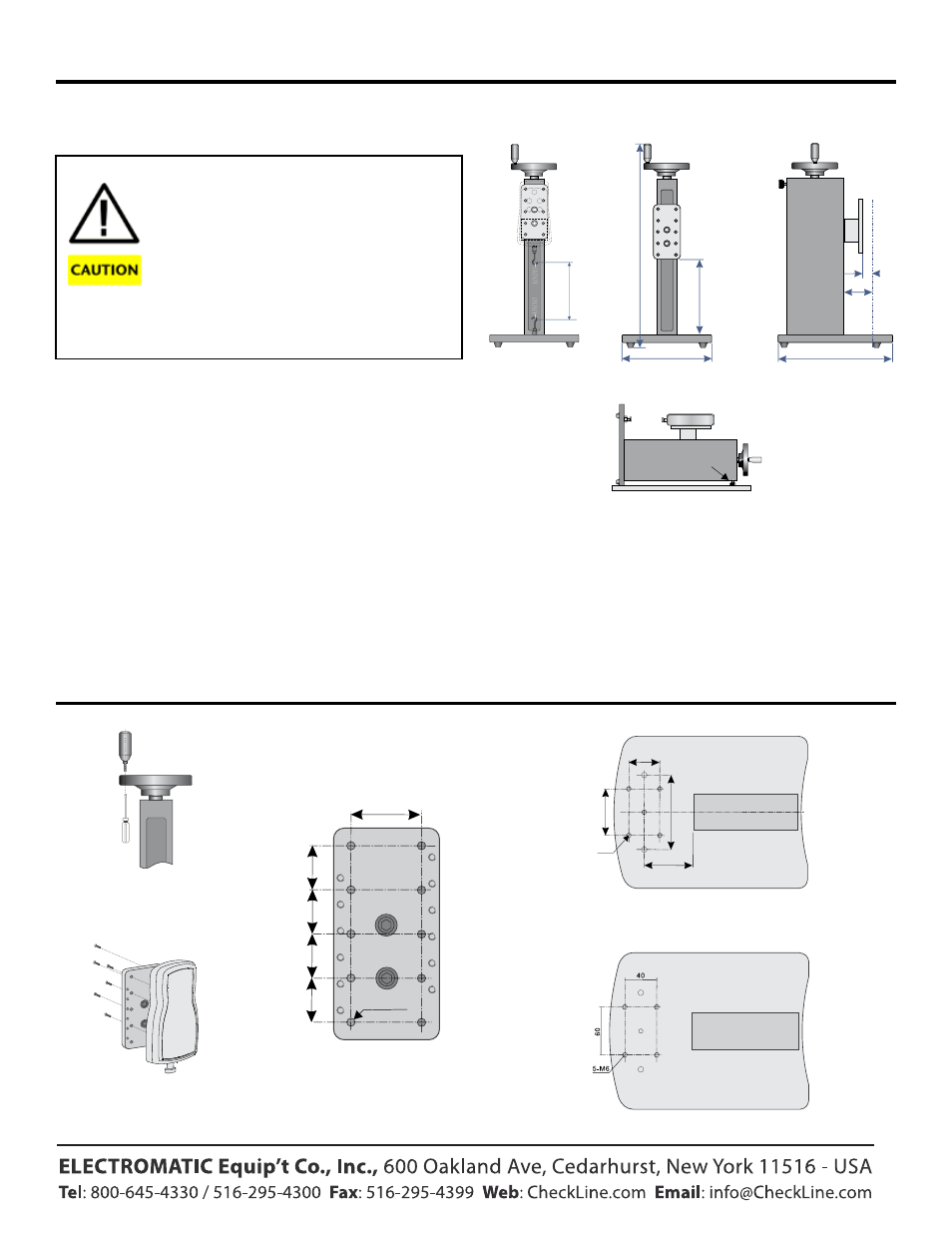

FGS-250W Manual Hand Wheel Test Stand

Operation Manual

The rated load of the test stand is 250 lb (125 kg).

The maximum displacement is 9˝(230 mm) without

optional tensile tester. Do not overload or damage to

the test stand can occur.

Do not use the test stand in water or oil or allow any

liquids to get into the moving mechanisms of the

stand. Improper operation and malfunction will result.

Do not disassemble, repair or alter the test stand.

Warranty will be voided and damage may result.

SPECIFICATIONS

Capacity: Up to 250 lbf (125 kg); 143 lbf (65 kg) with optional

Tensile frame.

Travel:

0.12˝ (3 mm)/turn

Stroke:

9˝ (230 mm) max.; 10.24˝ (260 mm) max. with Tensile

Frame kit.

Dimension:

9.8 x 7.7 x 17.5˝ (250 x 196 x 445 mm)

Weight: 15.4 lb (7 kg)

Warranty: 1 year

Packing List: Test Stand (1), Handle in Hand Wheel (1), Adapter

Screw (M6) (1), Screw M4 x 16 (for force gauge) (6)

9

6

6

0

40

57

5-M6

250

57

4

4

5

196

2

3

0

(m

a

x

)

13.8

Level adjust bolt

40

2

5

2

5

2

5

2

5

10- 5

Ø

The FGS-250W Manual Hand Wheel Operated Test Stand is

specifically designed for tensile and compressive force testing

and destructive or failure testing for research applications in a

multitude of industries.

The FGS-250W movement is created from a trapezoidal screw

drive with integral nut. Combined with its top-mounted wheel

that smoothly turns with minimal effort, fine, stable resolution is

achieved during operation.

The FGS-250W offers dual functionality by being able to be used

in either the vertical or horizontal positions with no added equip-

ment required. Simply lay unit on its back and level with the ad-

justment screw and you now can run horizontal tests.

Optional accessories include a Digital Scale and a Tensile Frame

adapter kit which enables extended clearance for tensile tests.

BASE PLATE

HANDLE

FORCE GAUGE

FIXTURE ATTACHMENT

MOUNTING

GAUGE MOUNTING

PLATE

HORIZONTAL

26

0(

m

ax

)

12

5(

m

ax

)