Checkline TI-CMXDLP User Manual

Page 35

– 35 –

6.2 Probe Zero

The next step is to perform a probe zero. The zero function is a very important and

necessary function that must be done prior to calibration. It should be done on a regular

basis. In fact, the TI-CMXDLP has been programmed to force this issue at regular

intervals during operation if it hasn’t been done. If the TI-CMXDLP is not zeroed

correctly, all the measurements taken may be in error by some ixed value. When the

TI-CMXDLP is using the auto zero (electronic zero), the TI-CMXDLP can be in any

measurement mode. However, when the manual zero is being used, the TI-CMXDLP

must be in pulse-echo mode in order to perform the zero. The TI-CMXDLP will also see

to it that this occurs by simply forcing the gauge into this mode when zero. Therefore,

if the TI-CMXDLP is in the echo-echo measurement mode and a manual zero is being

performed, the TI-CMXDLP will put the gauge into pulse-echo mode automatically

before performing the zero. While this is a very convenient feature of the TI-CMXDLP,

the user should be sure to check the measurement mode following calibration to be

sure the TI-CMXDLP is in the desired mode. The following steps outline both of these

techniques.

The TI-CMXDLP is equipped with two zero options:

1. Off Block Zero (Automatic Probe Zero) – When this feature is enabled the

TI-CMXDLP will do an electronic zero automatically, eliminating the need for a

zero disk or block.

2. On Block Zero (Manual Probe Zero) – When this feature is enabled the transducer

must be placed on the Probe Zero Disk (battery cover located on the top of the unit.

Both zero procedures are outlined as follows:

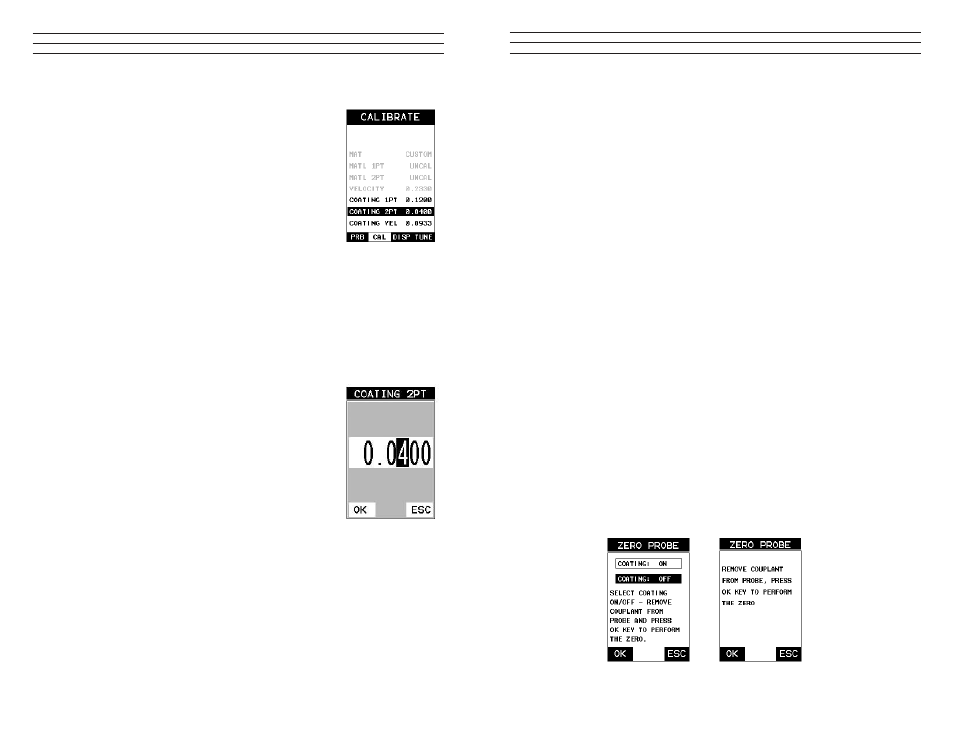

Performing an Auto Probe Zero (Off Block)

1. Be sure all couplant has been removed from the face of the transducer.

2. Press the OK key to perform the automatic probe zero, or ESC key to cancel the

zero operation.

3. The screens illustrated above will be briely displayed followed by the main

measurement screen. The TI-CMXDLP is ready to be calibrated.

Coating Probe Identified

Coating Probe Not Identified

– 70 –

Two Point Calibration

NOTE: Use the minimum coating sample for the two point

calibration.

1. Physically measure the thinner of the two samples of the

coating, as close as possible to the minimum expected

coating measurement range, using a set of calipers or a

digital micrometer.

VERY IMPORTANT: If coating measurements will be

made with the coating applied to a metal surface, the

calibration must be done in the same manner,with the

samples coupled to a metal surface. However, if the coating

will be measured as a stand alone material, the calibration

must be performed the same way.

2. Apply a drop of couplant on the transducer and place the transducer in steady

contact with the thinner of the two coating and samples. Be sure that the reading

is stable and the repeatability indicator, in the top left corner of the display, is fully

lit and stable. Press the MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right and the ESC key multiple times to tab left

until the CAL menu is highlighted and displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the

sub menu items until COATING 2PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the

digit locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctly displayed.

8. Press the OK key to calculate the velocity and return to

the menu screen, or ESC to cancel the coating one point

calibration.

9. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

NOTE: CHECK YOUR CALIBRATION! Place the transducer back on both calibration

points. The coating thickness readings should now match the known thickness values of

each sample. If the thickness is not correct, repeat these steps above.