Checkline TI-CMXDLP User Manual

Page 26

–26 –

4.0 PRINCIPALS OF ULTRASONIC

MEAS

UREMENT

4.1 Time versus thickness relationship

Ultrasonic thickness measurements depend on measuring the length of time it takes

for sound to travel through the material being tested. The ratio of the thickness versus

the time is known as the sound velocity. In order to make accurate measurements, a

sound velocity must be determined and entered into the instrument. The accuracy of a

thickness measurement therefore depends on having a consistent sound velocity. Some

materials are not as consistent as others and accuracy will be marginal. For example,

some cast materials are very granular and porous and as a result have inconsistent sound

velocities. While there are many different ultrasonic techniques to measure thickness,

which will be discussed below, all of them rely on using the sound velocity to convert

from time to thickness.

4.2 Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the material

being measured. Not all materials are good at transmitting sound. Ultrasonic thickness

measurement is practical in a wide variety of materials including metals, plastics, and

glass. Materials that are dificult include some cast materials,concrete, wood, iberglass,

and some rubber.

4.3 Range of measurement and accuracy

The overall measurement capabilities, based on the wide variety of materials, is

determined by the consistency of the material being measured. The range of thickness

that can be measured ultrasonically depends on the material as well as the technique

being used and the type of transducer. Thickness measurements can be made from a

minimum of 0.010 inch to 9.999” in steel. However, the maximum attainable thickness

is much less for more attenuative materials (materials that absorb sound).Accuracy,

is determined by how consistent the sound velocity is through the sound path being

measured, and is a function of the overall thickness of the material. For example, the

velocity in steel is typically within 0.5% while the velocity in cast iron can vary by 4%.

4.4 Couplant

All ultrasonic applications require some medium to couple the sound from the

transducer to the test piece. Typically a high viscosity liquid is used as the medium. The

sound frequencies used in ultrasonic thickness measurement do not travel through air

eficiently. By using a liquid couplant between the transducer and test piece the amount

of ultrasound entering the test piece is much greater.

–79 –

5. Once the desired law mode is displayed, press the MEAS key to return to

measurement mode.

NOTE: All the features previously discussed in this manual can be used to adjust and

ine tune the TI-CMXDLP while in Flaw Mode.

NOTE: When law mode is activated, a transducer delay will still be conigured from

the previously loaded transducer. This will only affect the starting point from the initial

pulse from being at zero. The zero delay can be set to zero by loading the default setup

located in the setup menu. Alternatively,the user can load a factory law mode setup,

from the setups folder, and begin making any adjustments necessary. Refer to section

10.10 Graphics Options (look & feel)We’ve added a couple of graphic interface features

to the TI-CMXDLP , accommodate customer requests we’ve received in the past.

These features only serve as cosmetic items, and do not change the functionality of the

TI-CMXDLP in any way.

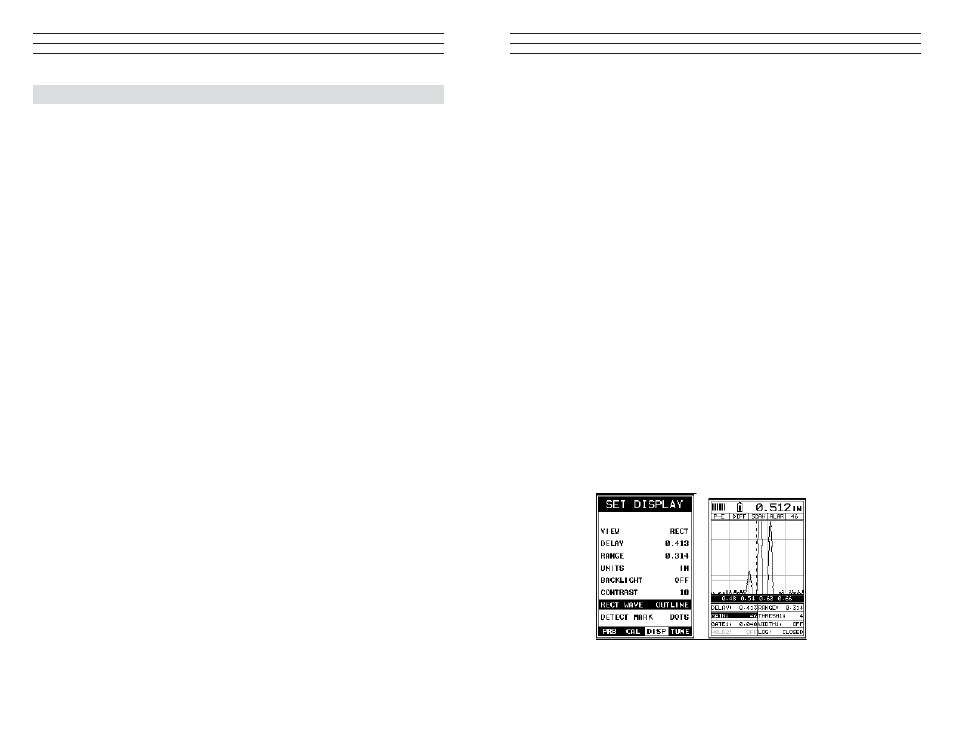

10.10 Graphics Options (look & feel)

We’ve added a couple of graphic interface features to the TI-CMXDLP , accommodate

customer requests we’ve received in the past. These features only serve as cosmetic

items, and do not change the functionality of the TI-CMXDLP in any way.

RECT Wave: The rectiied wave feature is only functional when using RECT wave

view and provides the user the following display options:

Outline – Draws the unilled outline of the waveform.

Filled – Draws a illed version of the waveform.

Detect Mark – The detect mark is another look and feel option for displaying the

detection indicator.

Outline