Rockwell Automation Motion Analyzer Software User Manual

Page 98

98

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 2

Sizing Your System

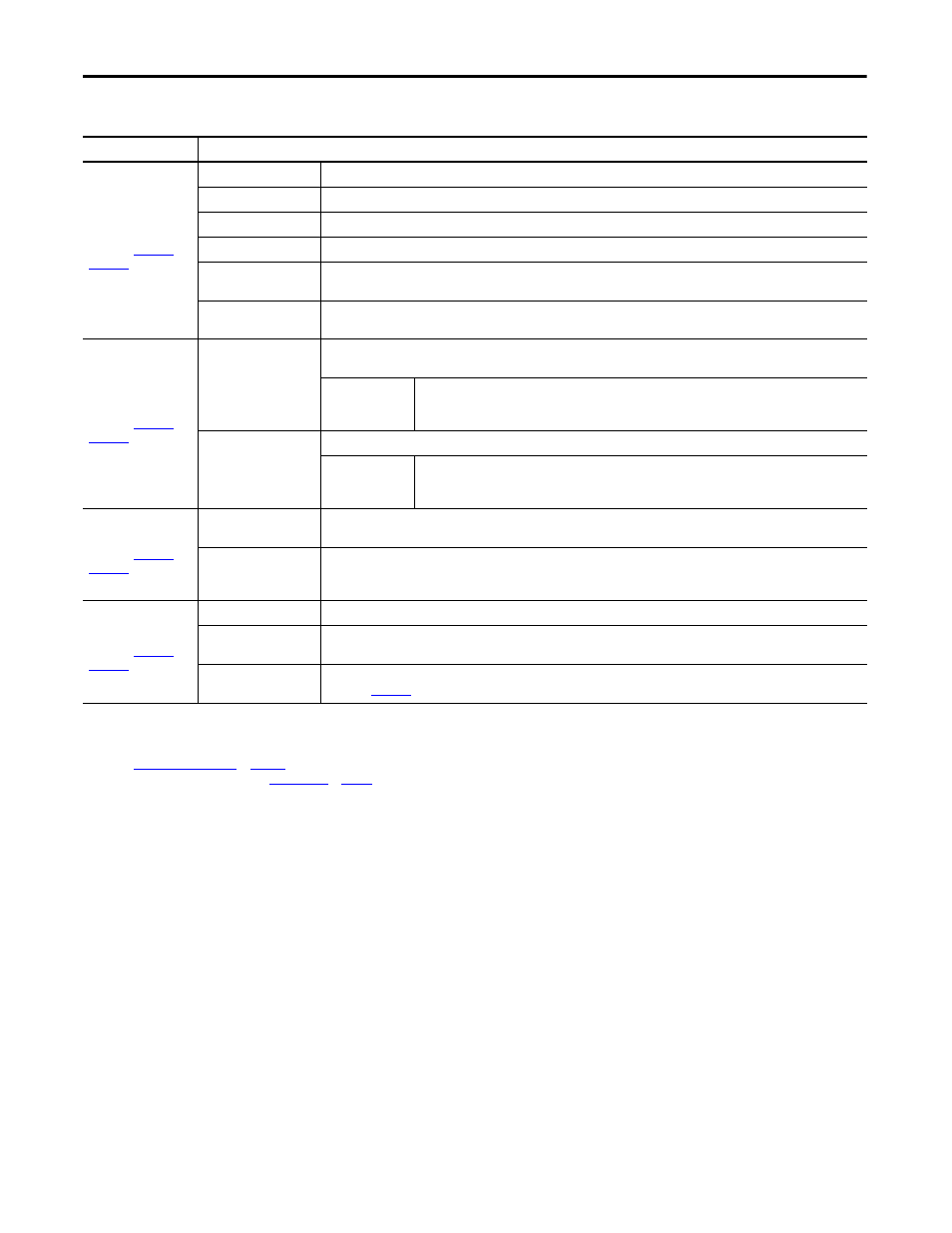

Table 57 - Press Roll Feed Parameters

Parameter

Description

)

Moving Material Mass

The mass of the material in the loop and on the flat before the Nip/Feed rolls.

(3)

Bias Force

The force required to overcome the force of gravity on the loop.

Drive Roll Diameter

The diameter of the roll in direct contact with the strip, driven from the motor.

Total Roll Inertia

(2)

The total inertia of the strip material at the drive shaft.

Cut (Waiting) Time

The time during which the material must be stationary in an accurate position. This value is only required for Press Roll Feed -

Constant Time applications (refer to the red boxes in images above).

Cut (Waiting) Angle

The crank angle during which the material must be stationary in an accurate position. This value is only required for Press Roll

Feed - Constant Angle applications (refer to the red boxes in images above).

Critical Preferences

(1)

)

Max Average Line Speed

Select this option for data entry when the maximum design speed of the constant-speed sections of the line is known. This

speed does not refer to the peak velocity of the feeder section, which is determined by Motion Analyzer software.

Min. Cut length at

Max line speed

When you select the option to enter data based on Max Average Line Speed, this data is required. This is

the critical condition on which the sizing process is performed. To cut shorter lengths than this critical

length, the line speed must be reduced.

Cuts/min

Select this option for data entry when the number of cuts made by the system per minute is known.

Max. Cut length at

Cuts/min

When you select the option to enter data based on Cuts/min, this data is required. This is the critical

condition on which the sizing process is performed. To cut longer lengths than this critical length, the

line speed must be reduced.

)

Settling Time

This is the time required for the system to achieve the required position accuracy before the cut commences. The finer the

required accuracy, the longer the settling time value. This time is typically 20 to 75 ms for an A servo system.

Cosine Compensation

This option is only required for Press Cutter Knife Drive applications. The Cosine Compensation is used to make sure that while

the press cutter knife is in contact with the material being cut, the horizontal component of the knife’s velocity matches the

material speed.

Motion Type Properties

(label 4 in

)

Linear

Select this option for standard linear acceleration and deceleration ramps.

S-Curve

Select this option for ‘S’ shaped acceleration and deceleration ramps that are used to produce smoother motion. You need to

enter the percent jerk value for this option.

Triangular Move

Select this option for a triangular load profile. This option is only required for Press Roll Feed - Constant Angle applications (see

red box in

(1) At very long cut lengths, the limiting factor, determined by the design speed of the leveler rolls and unwinder, is the maximum line speed. As cut length is reduced, the servo has to index more and more

rapidly until the peak or RMS (root mean squared) torque limit is reached. To cut shorter lengths than this critical length, the line speed must be reduced. Sizing is based on this critical length, maximum

line speed and cut time, which are typically specified.

(2) Use the

on

to calculate the inertia value for your application, if the value is not readily available.

(3) You can enter this data manually or use the

, to determine the value.