Rockwell Automation Motion Analyzer Software User Manual

Page 115

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

115

Sizing Your System

Chapter 2

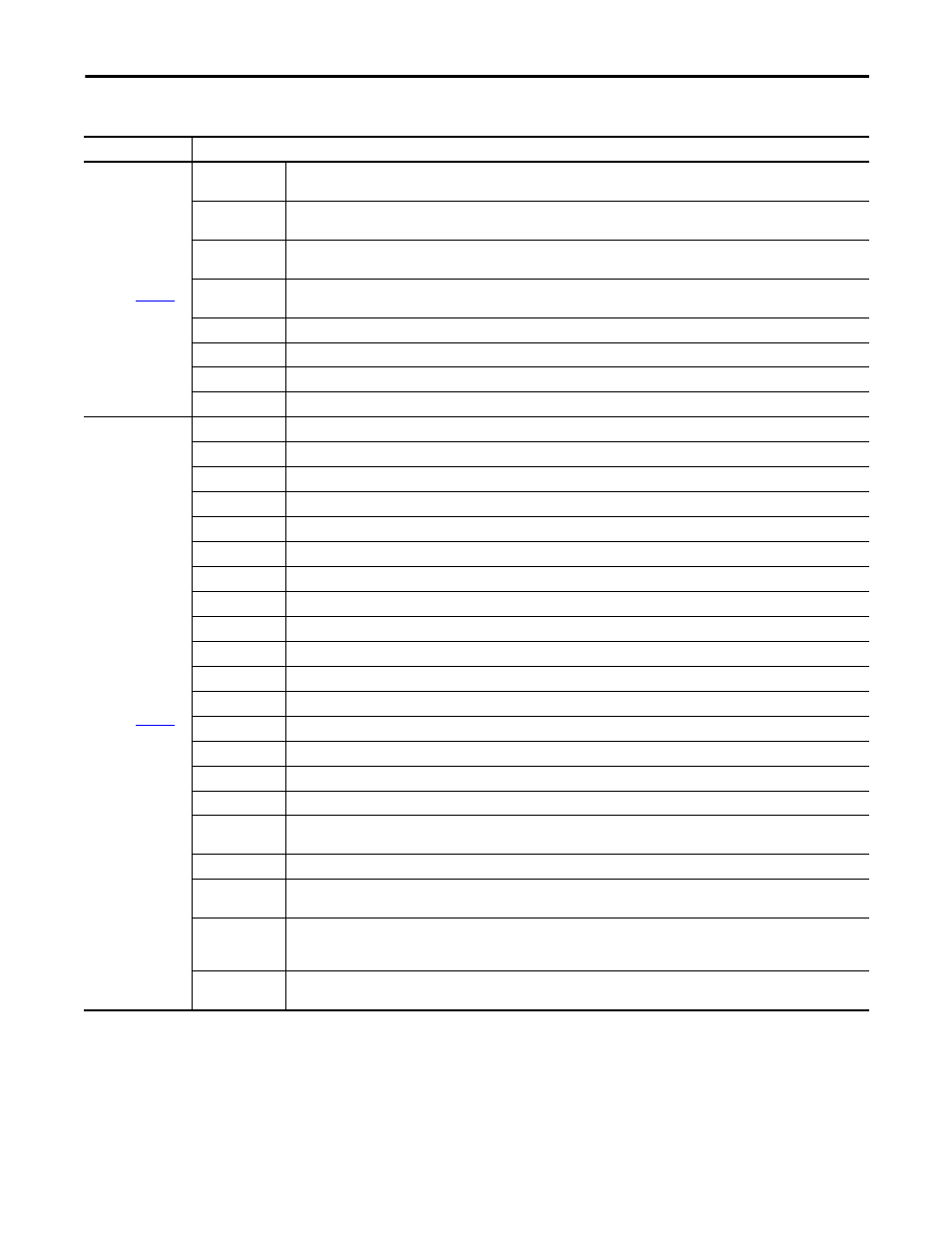

Table 68 - Four Bar Linkage Properties

Parameter

Description

Animated Display

(1)

(label 1 in

)

Vertical Slider

(left)

This slider sets the crankshaft inclination and should be set before starting the animation. Click 0y to set the angle to 90°. The current

angle is displayed in the Mechanical Data window.

Horizontal Slider

(top)

This slider sets the linear slide inclination. Click 0z to set the angle to 0°. The current angle is displayed in the Mechanical Data window.

The true angle to the horizontal is dependent on both slider positions because it is a compound angle.

Horizontal Slider

(scale)

This slider sets the display scale.

Horizontal Slider

(Speed)

This slider sets the animation speed. The black arrow in the plot represents the external force, and the arrow length is proportional to

the applied force.

Animate

Click to run the simulated crank image through the specified motion profile.

Stop

Click to stop the animation.

Analyze

Click to display the bar graphs that show the contribution of each mechanical component to the inertia and torque values.

Calculate

Click to calculate the external torque and reflected inertia values that will be applied.

Mechanical Data

(label 2 in

)

Link 1 Length

Distance between Pivot 1 and Pivot 2.

Link 1 Inertia

(2)

Inertia of Link 1.

Link 1 Start Angle

Initial angle between Link 1 and X Axis. Angular load profile only.

Link 2 Length

Distance between Pivot 2 and Pivot 3.

Link 2 Mass

Mass of Link 2.

Link 2 CG

Link 2 Center of Gravity with respect to Pivot 2.

Link 2 Inertia

Inertia of Link 2 about its own center of gravity.

Load Pivot X

X distance between Pivot 1 and Pivot 4.

Load Pivot Y

Y distance between Pivot 1 and Pivot 4.

Load Link Length

Distance between Pivot 3 and Pivot 4.

Load Inertia

Inertia of the load (Link 3) about its own center of gravity.

Load Mass

Mass of the load (Link 3.)

Load G of G Radius

Distance between Pivot 4 and center of gravity of the load (Link 3.)

Load G of G Angle

Angle between the lines that make up the center of gravity of the load (Link 3), Pivot 4, and Pivot 3.

Link 1 Start Angle

Link 1 angle when force is applied.

Force at Start

Magnitude of the force at the starting point.

Force at End

Magnitude of the force at the ending point. If the Force at Start is different from the Force at End, the force varies between these two

limits according to gudgeon pin position or crank angle. If the values are equal, a constant force is applied.

Force Orientation

Force orientation from the X axis.

Draw Start

Position

Click to show the geometry at the start angle/position.

Export Logix Cam

Click to transfer the geometrical data to the clipboard for pasting into the RSLogix 5000 Cam Editor. The master axis is a virtual axis

while the slave axis is the crank axis. A trapezoidal move of the virtual axis then produces a trapezoidal profile at the gudgeon pin. The

master data must increase positive so only that part of the cam that satisfies this requirement is exported.

Pivot 1 Axis

Inclination

Displayed value is the angle of the crank shaft with respect to the XY (horizontal) plane. 90° indicates vertical, and gravity has no

effect.