Advanced considerations - counterbalances – Rockwell Automation Motion Analyzer Software User Manual

Page 84

84

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 2

Sizing Your System

2.1.1.1. Advanced Considerations - Counterbalances

In a counterbalanced system, unbalanced mass should be entered as Table Mass

and balanced mass as Belt/Chain Mass. Values for Table Mass, Belt/Chain Mass,

and/or Slide Mass may be entered on the Mechanism tab (a future step in the

workflow) if a Belt Drive, Lead Screw, Chain and Sprocket, or Rack and Pinion

are selected.

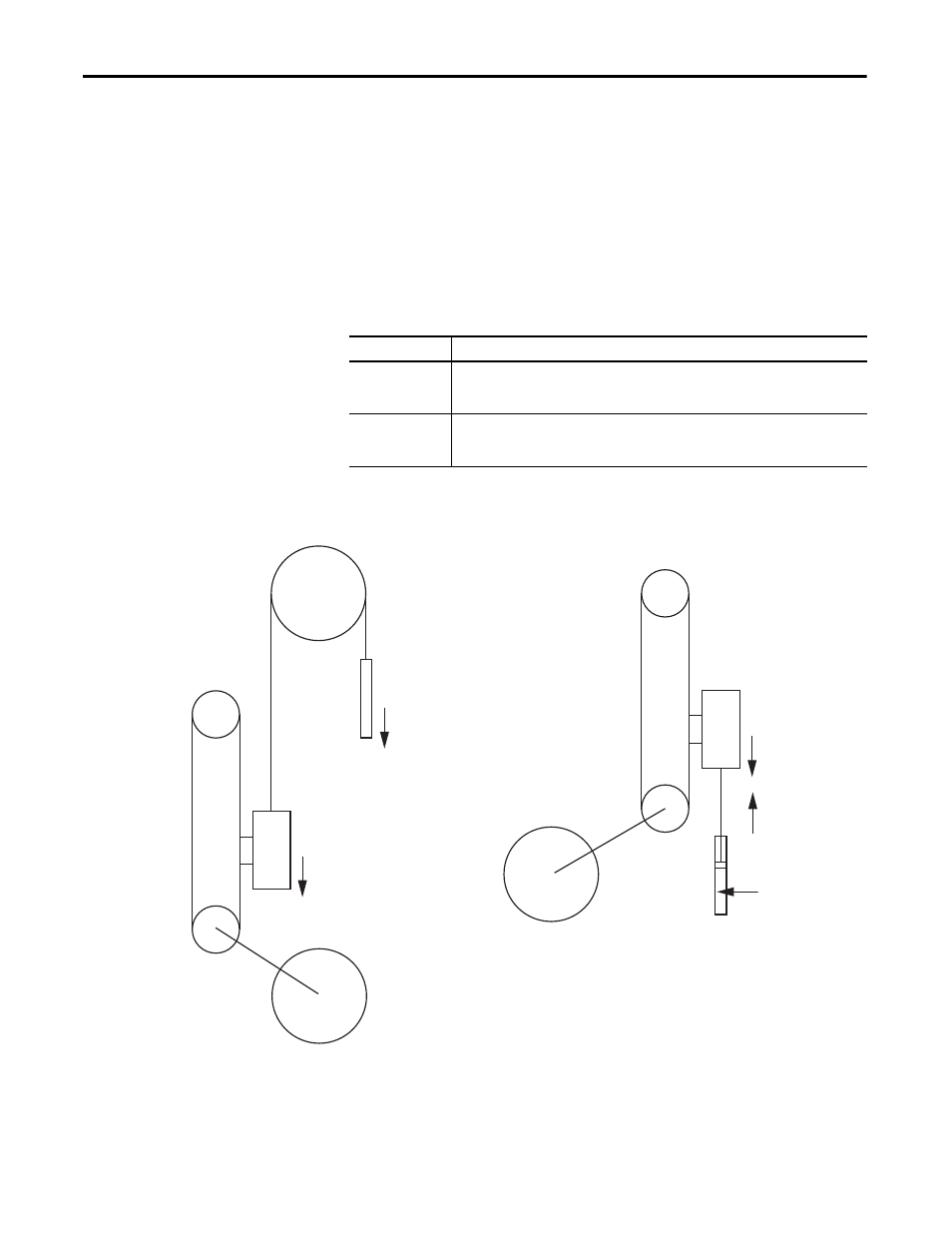

There are two main types of counterbalance.

Table 50 - Counterbalance Types

Figure 67 - Counterbalance Types

Type

Description

Mass

Counterbalance

A 100% counterbalance doubles the load mass entered on the Load tab. Friction is usually

negligible and the net force is zero. Accelerations are normally limited to less than gravity

(9.81 m/s

2

) to maintain the suspension tension.

Force

Counterbalance

A 100% counterbalance means there is zero net force, but usually adds significant friction,

especially hydraulic types. For example, pneumatic, hydraulic, or spring. The increase in load

mass is usually negligible.

Counterbalance Mass

Mass Counterbalance

Force Counterbalance

Counterbalance

Cylinder

Air Pressure

Force

Weight

Weight

Weight

Drive Belt

Drive Belt

Load Mass

Load Mass

Motor

Motor