Rigid coupling, Backlash – Rockwell Automation Motion Analyzer Software User Manual

Page 234

234

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 3

Understanding Your System Solution

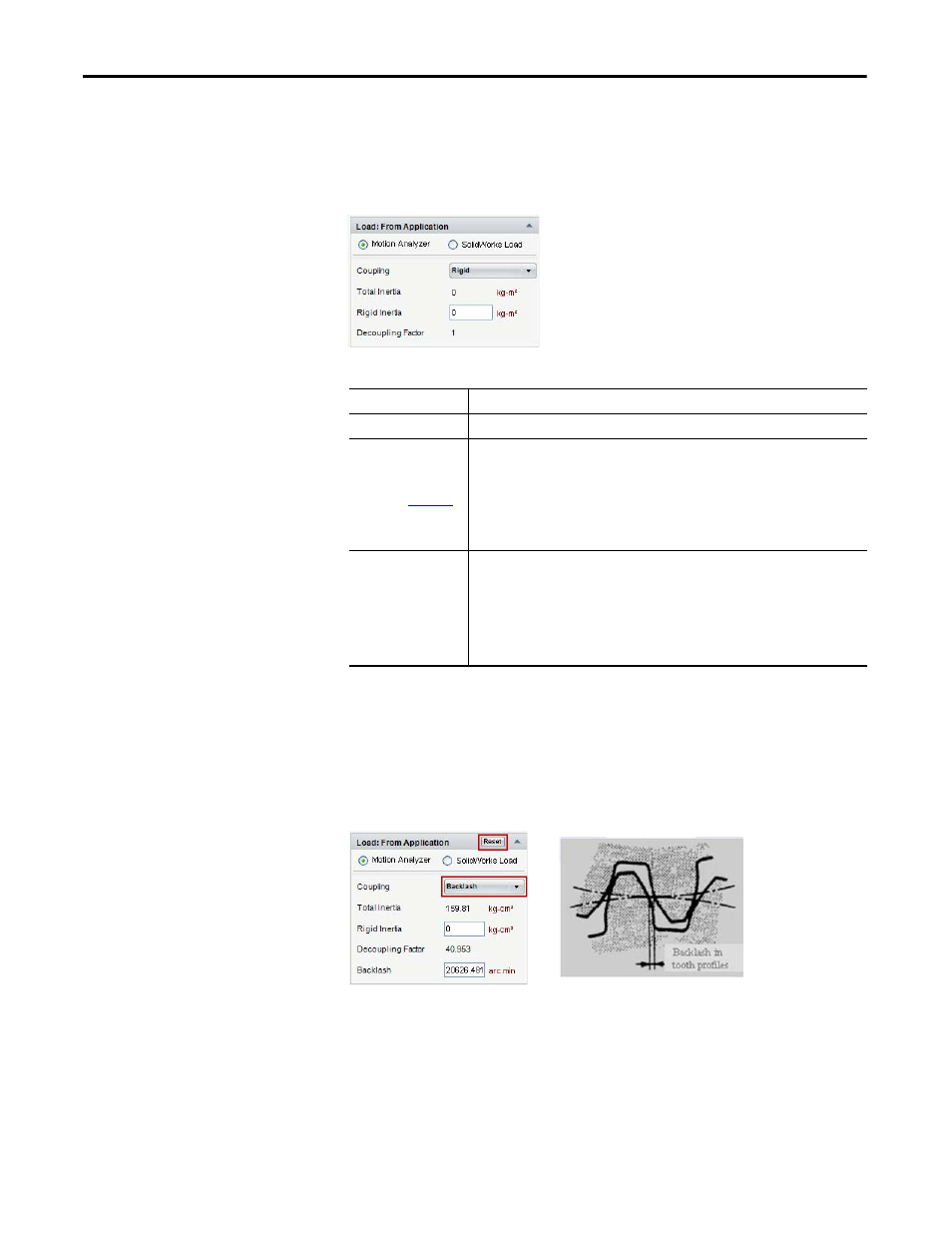

3.2.2.4.1.1.1. Rigid Coupling

Rigid coupling occurs when the load is rigidly coupled to the motor.

Figure 171 - Rigid Coupling

Table 136 - Rigid Coupling Options

3.2.2.4.1.1.2. Backlash

Backlash occurs (for example) when a gearbox is added to the motor. Choosing

Backlash enables an additional field, in addition to the Rigid coupling fields,

where you can enter a backlash value.

Figure 172 - Backlash Coupling

Options

Description

Total Inertia

Maximum load inertia reflected to the motor shaft.

)

Any part of the load inertia that is rigidly attached to the motor shaft. This becomes

significant only when resonance or backlash is present because it becomes effectively part

of the motor. Any inertia entered here is subtracted from the Load inertia leaving the total

(system) inertia unchanged.

For example, a gearbox always has backlash, but its input shaft/pinion is normally coupled

rigidly to the motor shaft. This effectively becomes part of the motor, creating a higher

inertia motor. This can significantly alter the performance of an axis.

Decoupling Factor

This factor is much more indicative of potential dynamic performance than the

conventional Inertia Ratio. Velocity Bandwidth is increased by this factor when the load is

decoupled. Instability typically results beyond 2 unless gains are reduced. Anything greater

than 1 starts to impact performance.

DF = Jdc / (Jm + Jrc) + 1

Where, DF = Decoupling Factor, Jdc = decoupled load inertia,

Jm = motor inertia, Jrc = rigidly coupled load inertia