Specify your linear load mechanism, Mechanism type – Rockwell Automation Motion Analyzer Software User Manual

Page 178

178

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 2

Sizing Your System

2.3. Specify Your Linear Load

Mechanism

A linear load mechanism is used to convert rotary motor torque to linear motion

through a transmission (belt drive, lead screw, chain and sprocket, or rack and

pinion), where thrust from a linear motor, electric cylinder, or linear stage

produces linear motion directly.

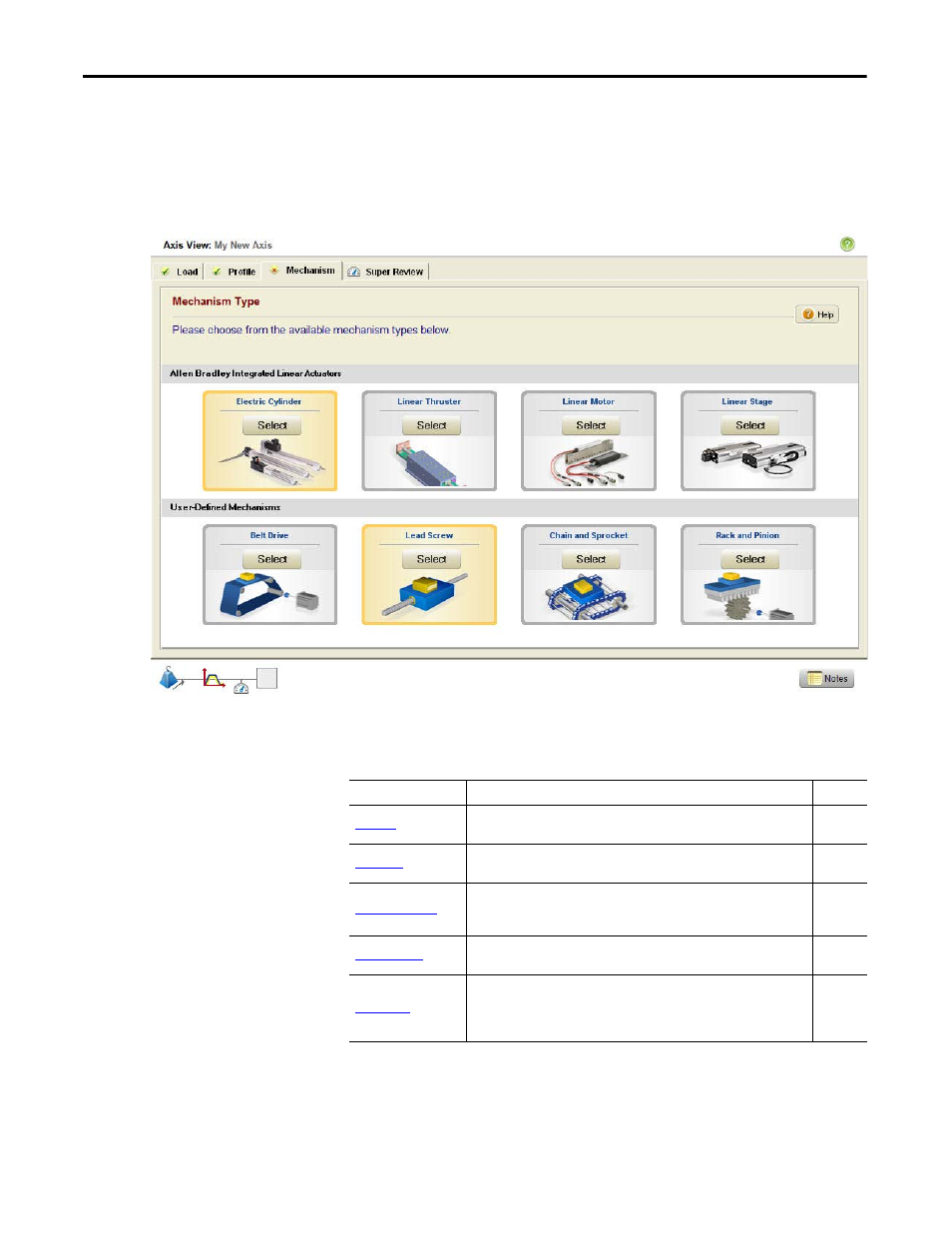

Figure 130 - Mechanism Type

The following mechanisms are available in Motion Analyzer software.

Table 101 - Mechanism Types

Type

Description

Page

A rotary motor coupled to a timing pulley that drives a flexible toothed belt,

with its coupled load, back and forth between two idler pulley guides.

A lead screw is coupled to a rotary motor and causes relative linear motion

between a rotating screw and its non-rotating nut.

A chain and sprocket is a rotary motor coupled to a sprocket wheel that drives a

linked chain, with its coupled load, back and forth between idler sprocket

guides.

A rack and pinion is a rotary motor coupled to a toothed pinion wheel that

engages a toothed rack to create relative motion between the two elements.

Linear motors are either iron-core and ironless motors that directly create

linear thrust. Their separate sections (coil and magnet channel) produce

relative motion between a carriage and its base along the user-supplied linear

bearing guides.