Resistive brake module, Load data – Rockwell Automation Motion Analyzer Software User Manual

Page 252

252

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 3

Understanding Your System Solution

3.3.2. Resistive Brake Module

Check Resistive Brake Module to enable selection and analysis of resistive brake

modules (RBM).

RBM modules provide controlled motor braking by connecting resistors across

the windings. An RBM module does not stop the motor if the axis has a thrust,

an external force, or a gravity force as a result of being inclined. The RBM

module only produces motor torque if the motor is moving and may act as a

speed limiter. When this happens, it is essential to use a fail-safe brake. The motor

brake may not be sufficient to stop the system and should not be applied when it

is in motion.

The stopping behavior depends on the initial velocity, inertia, contactor delay,

and the value of resistance in the RBM module. This tab enables you to select the

optimum resistive brake module.

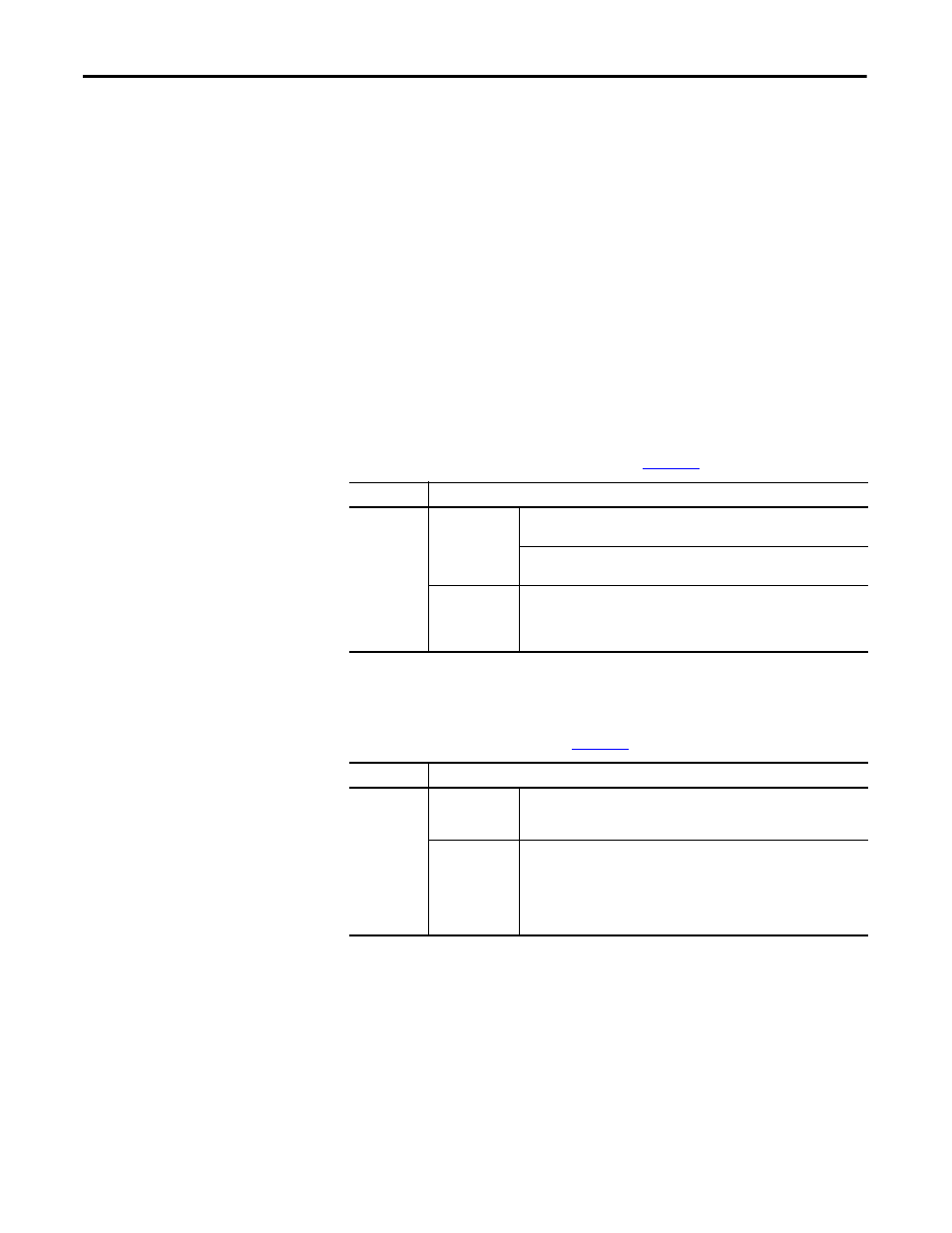

Table 148 - Resistive Brake Module Properties (refer to

3.3.3. Load Data

Table 149 - Load Data Properties (refer to

Parameters

Description

Resistive Brake

Modules

Start Speed

Select the Max. Appl. Speed option if you are sure this value cannot be

exceeded.

Select the Max. Motor Speed option for a high level of security. This is generally

the worst case scenario.

Plot Time

This sets the time scale for the distance calculation and graphical display. To

zoom in on the left-hand end of the graph, decrease the Plot Time. Increase the

Plot Time if the system has not stopped, to evaluate longer stopping times, and

to view the ultimate speed when not stopping.

Parameters

Description

Load Data

Mechanism Data

Select this option to use the External Torque and Load Inertia values from the

system data that has been entered in previous tabs. This is the torque on the

motor produced by any external torque or force.

User Defined

Select this option to manually enter External Torque and Load Inertia values. In

some cases, the maximum inertia/thrust may not coincide with the maximum

speed. When this happens, the default (maximum speed and inertia/thrust)

may produce an over-cautious solution. Advanced users may want to enter

their own value for the inertia and thrust torque (with reference to the motor)

for the maximum speed condition.