Lead screw, D in, Table 104 – Rockwell Automation Motion Analyzer Software User Manual

Page 181

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

181

Sizing Your System

Chapter 2

2.3.2. Lead Screw

A lead screw is coupled to a rotary motor and causes relative linear motion

between a rotating screw and its non-rotating nut.

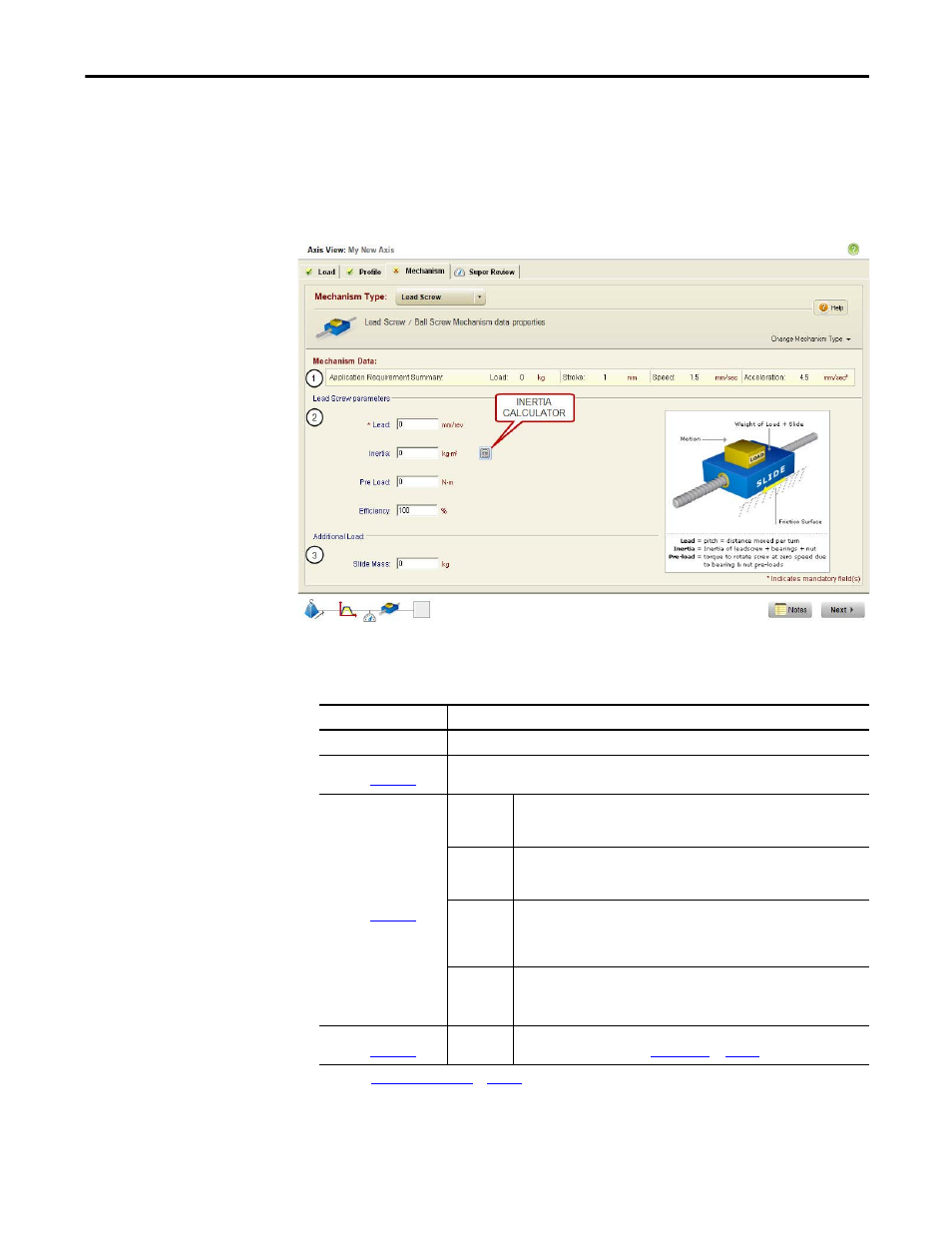

Figure 133 - Mechanism Type - Lead Screw

Enter the following parameters for lead screw mechanisms, if relevant.

Table 104 - Lead Screw Properties

Parameters

Description

Mechanism Type

From the pull-down menu, choose the mechanism type.

The Load, Stroke, Speed, and Acceleration values are calculated based on the parameters entered

in the previous Load and Profile tabs and displayed here for reference.

Lead Screw Parameters

(label 2 in

Lead

The distance that the slide moves per one full rotation of the screw shaft. Pitch is

sometimes used loosely to describe this parameter. Pitch is actually the distance

between adjacent threads and is equal to lead only for single start threads.

Inertia

(1)

The inertia of the lead screw in the event that the lead screw rotates and the nut

is stationary. Enter the inertia of the nut when the lead screw is stationary and

the nut rotates.

Pre Load

The friction torque produced by pre-loading the two nuts of a ball screw against

each other. This is done to reduce backlash and increase stiffness in the system.

Seal friction should be included in this value. This value can be obtained from the

manufacturer’s data and is normally quoted in data sheets.

Efficiency

The efficiency of the lead screw. This value is available from the manufacturer.

Plain Acme screw = typically 40…60%

Precision screw (with rolling elements) = typically 85… 90%

Slide Mass

The mass of the slide that travels along the lead screw. This mass is affected by

gravity if the inclination in the

on

is non-zero.

(1) Use the

to calculate the inertia value for your application, if the value is not readily available.