Chain and sprocket – Rockwell Automation Motion Analyzer Software User Manual

Page 182

182

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 2

Sizing Your System

2.3.3. Chain and Sprocket

A chain and sprocket is a rotary motor coupled to a sprocket wheel that drives a

linked chain, with its coupled load, back and forth between idler sprocket guides.

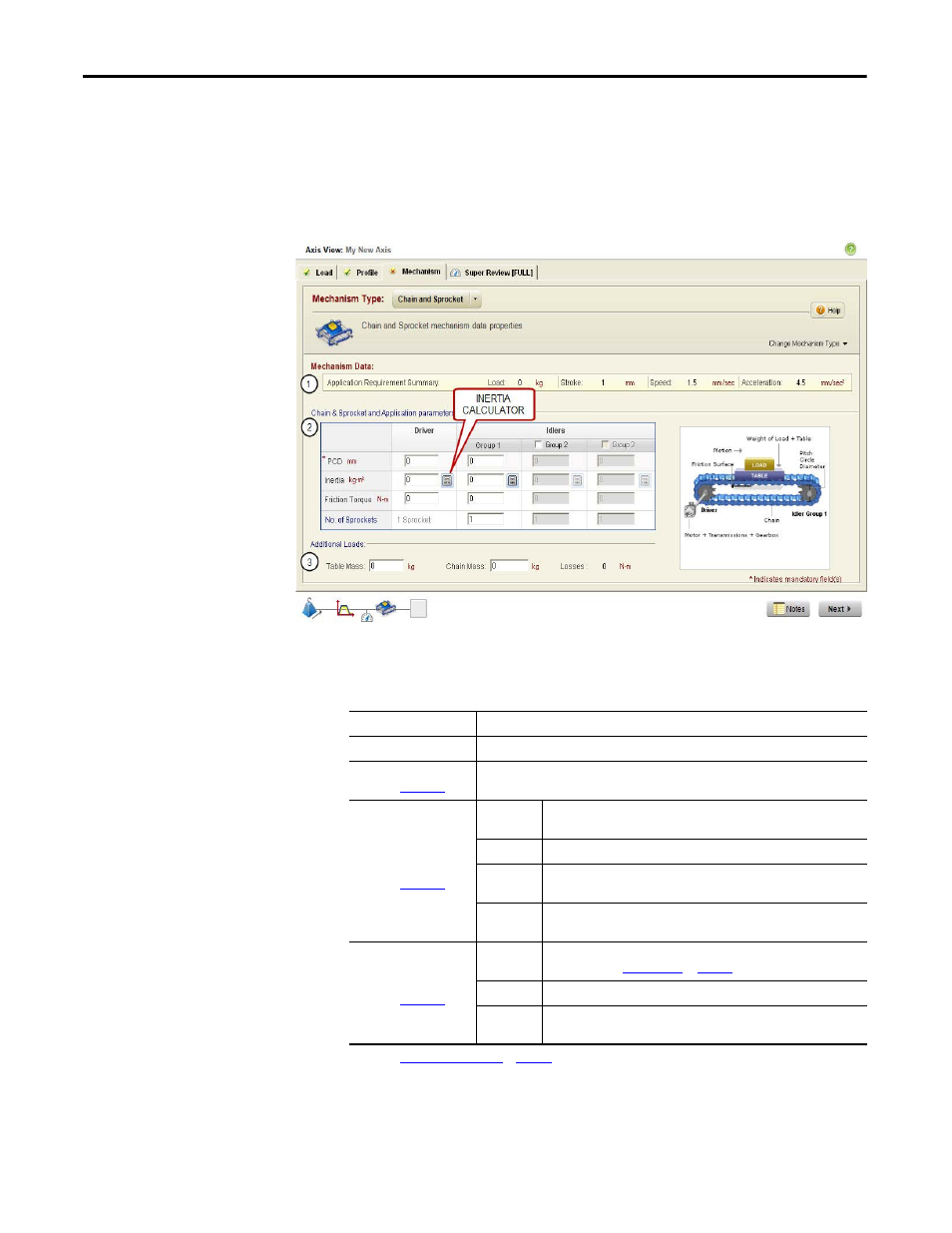

Figure 134 - Chain and Sprocket Dialog Box

Enter the following parameters for chain and sprocket mechanisms, if relevant.

Table 105 - Chain and Sprocket Properties

Parameters

Description

Mechanism Type

From the pull-down menu, choose the mechanism type.

Mechanism Data

(label 1 in

The Load, Stroke, Speed, and Acceleration values are calculated based on the parameters

entered in the previous Load and Profile tabs and displayed here for reference.

Chain and Sprocket

Application

(label 2 in

PCD

Pitch Circle Diameter. This can be calculated by multiplying the link pitch

by the number of teeth on the sprocket and dividing by pi.

Inertia

(1)

(1) Use the

to calculate the inertia value for your application, if the value is not readily

available.

The inertia of the driver and idler groups.

Friction

Torque

The torque loss due to friction at the driver or idler shaft. This value can be

obtained from the supplier or Engineering tables.

No. of

Sprockets

The number of sprockets for each idler group.

Additional Loads

(label 3 in

Table Mass

The mass of the linear load table. This mass is affected by gravity if the

inclination in the

is non-zero.

Chain Mass

The mass of the chain. This mass is not affected by gravity.

Losses

The total torque loss due to friction at the driver and the idler groups is

calculated and displayed here.