Axis stop, Controlled stop, Tab t – Rockwell Automation Motion Analyzer Software User Manual

Page 250

250

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

Chapter 3

Understanding Your System Solution

3.3. Axis Stop

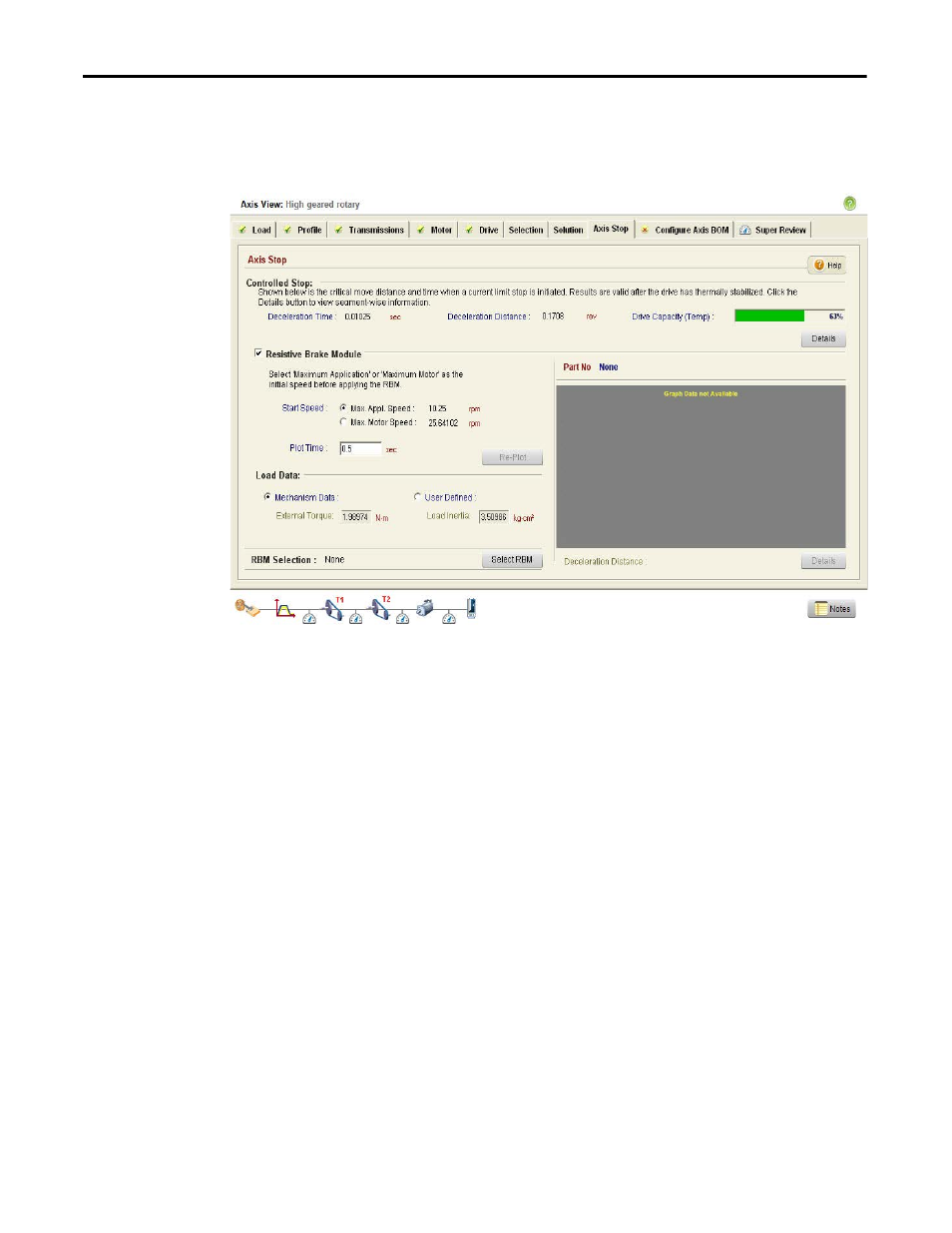

The Axis Stop tab is used to determine the time and distance that the system

takes to come to a stop.

Figure 195 - Axis Stop Dialog Box

For each profile segment, Motion Analyzer software finds the highest velocity

and evaluates the time and distance the axis takes to stop from that speed using

the maximum available axis current (for example, at maximum permissible

current limit for the axis). Motion Analyzer software displays the worst possible

scenario.

3.3.1. Controlled Stop

The critical time and distance for the motion profile for each axis are captured

and displayed in the Controlled Stop section of the tab. This gives the machine

designer a guide when determining over-travel limits. These figures are a guide

and do not necessarily show the worst possible case. In a runaway situation or if

the motion programming is faulty, the axis may hit an over travel limit at a higher

speed than those used in this calculation. Similarly, if the real load is greater than

that used in this calculation, the stopping time and distance will be greater. The

machine designer must perform a risk analysis of such situations. The Drive

Capacity (Temp) bar changes color depending on the capacity percentage; for

80%, the bar is yellow, and for 100% the bar is red.

Click Details to view the Controlled Stop Details dialog box. The Deceleration

Distance on both the motor and load sides, Deceleration Time, Amplifier

Utilization, and Energy Absorbed starting and ending values are displayed for

each profile segment.