Compute using inertia and ratio – Rockwell Automation Motion Analyzer Software User Manual

Page 193

Rockwell Automation Publication MOTION-UM004B-EN-P - October 2012

193

Sizing Your System

Chapter 2

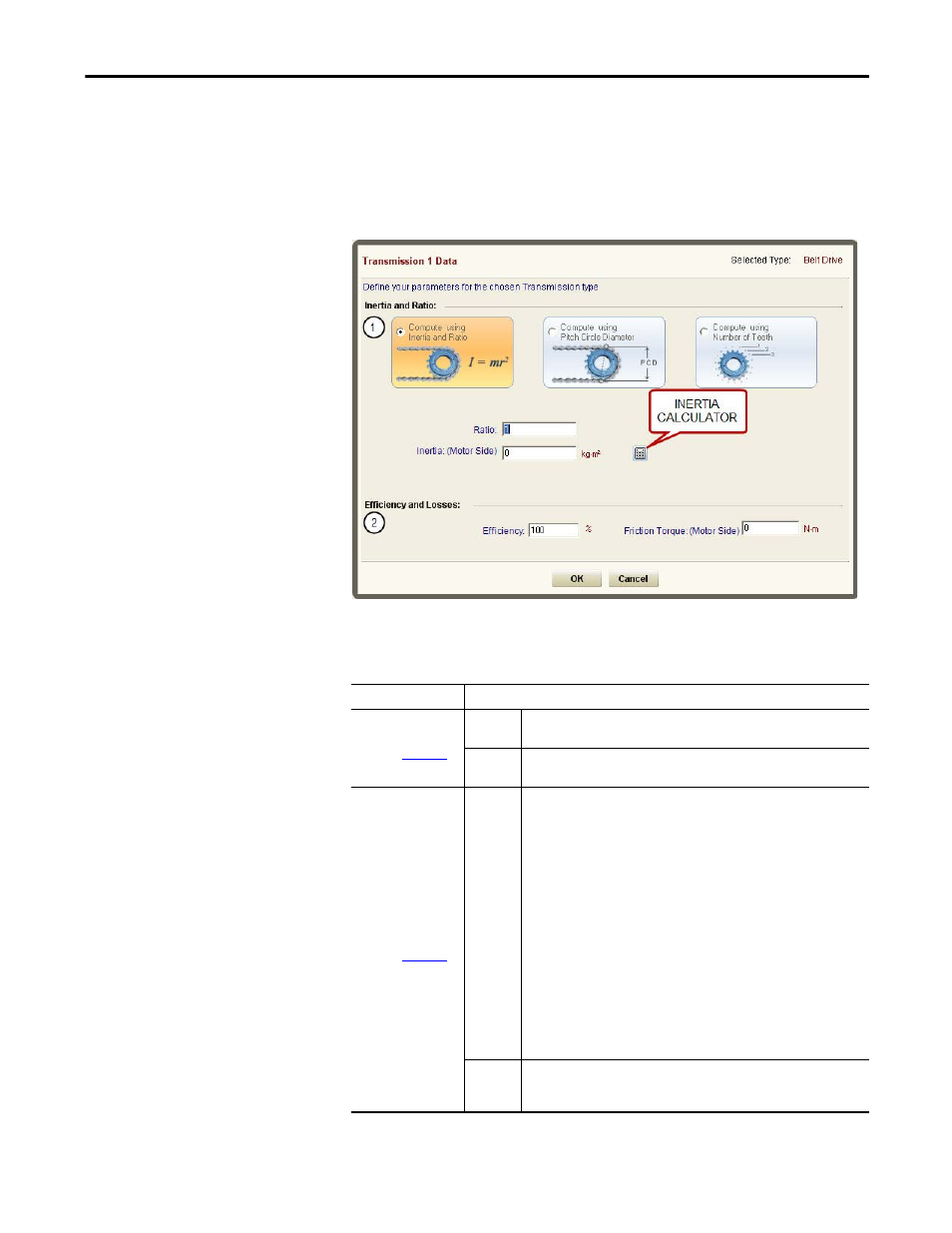

2.4.1. Compute Using Inertia and Ratio

Use this mode to directly enter the transmission component ratio and effective

inertia. This option is available for all transmission components.

Figure 142 - Compute Using Inertia and Ratio Dialog Box

Enter the following parameters for inertia and ratio, if relevant.

Table 113 - Compute Using Inertia and Ratio Properties

Parameters

Description

Inertia and Ratio

(label 1 in

)

Ratio

Transmission component ratio. If a straight-through coupling is being modeled,

set Ratio = 1.

Inertia

Inertia on the motor side (the rotor inertia and if a gearbox is present, the

inertia of the pinion attached to the rotor).

Efficiency and Losses

(label 2 in

)

Efficiency

Efficiency is widely misused. It refers to the ratio of output power to input

power for a single operating condition, but a servo system typically operates

over a wide range of operating conditions. A gearbox supplier normally

specifies the efficiency at an optimum point such as full load and full speed.

For example, a gearbox that has an output rating of 100 N•m (885 lb•in) and an

efficiency of 98%. This means that the losses at full load are 2 N•m (18 lb•in).

But because most of the losses in a gearbox are due to shaft seal friction and

churning of the lubricant, this would not reduce significantly at a lower load

torque.

In using this gearbox, a well-matched servo motor only has a continuous rating

around one third of the peak torque, and it is quite likely that the average

torque over the motion cycle would be even lower, for example about 20 N•m

(177 lb•in) at the gearbox output. The losses of 2 N•m (18 lb•in) amount to 10%

of the load on the motor, which can have a significant effect on the

temperature rise of the motor.

Motion Analyzer software overcomes this problem by dynamically computing

the real losses throughout the motion cycle, and thereby avoids

underestimating the effect of losses on the motor.

Friction

Torque

This is the torque caused by friction on the motor side between the rotor and

the transmission component. This value can be obtained from the supplier or

Engineering tables.