A.2.6 diameter calculator, A.2.7 flying splice unwinds – Rockwell Automation WebPak 3000 DC Drive Application Workbook Version 1.1 User Manual

Page 85

Using the WebPak 3000 Drive for Web Applications: The Basics

A-7

A.2.6 Diameter Calculator

The need for a diameter calculator function was established under the Type 2 field

current regulator design. However, the unwind and winder variable diameter

applications require instantaneous diameter information for the additional functions of

inertia compensation, taper tension, and control loop gain profiling.

The diameter calculator requires two signal inputs to perform its task. Web speed,

which is typically approximated by line speed reference, and motor speed are used to

calculate the running diameter as a software value, which is applied to modify the

drive system functions that have been programmed to be diameter sensitive.

The diameter calculator is capable of covering a maximum diameter range of 20:1.

Full roll diameter can be a maximum of 20 x core diameter up to a maximum of

120 inches.

A.2.7 Flying Splice Unwinds

The entry zone of a web process line can be either a single-position unwind drive or,

when the process is continuous, a two-position unwind drive with flying splice

operation. A flying splice two-position unwind is more complex then a single-position

winder due to the performance issues related to the splice sequence.

The individual unwind spindle drives have to support the steady state operation of

unwinding the web into the process under the primary tension control mode in addition

to accurately maintaining tension during the dynamics of the splice.

In some unwind flying splice machines, the need for a control function called “current

memory” may exist. This function changes the drive on the outgoing roll from its

primary tension regulator to a current regulator whose current reference is the

memorized value of its armature current just prior to being switched out of tension

operation.

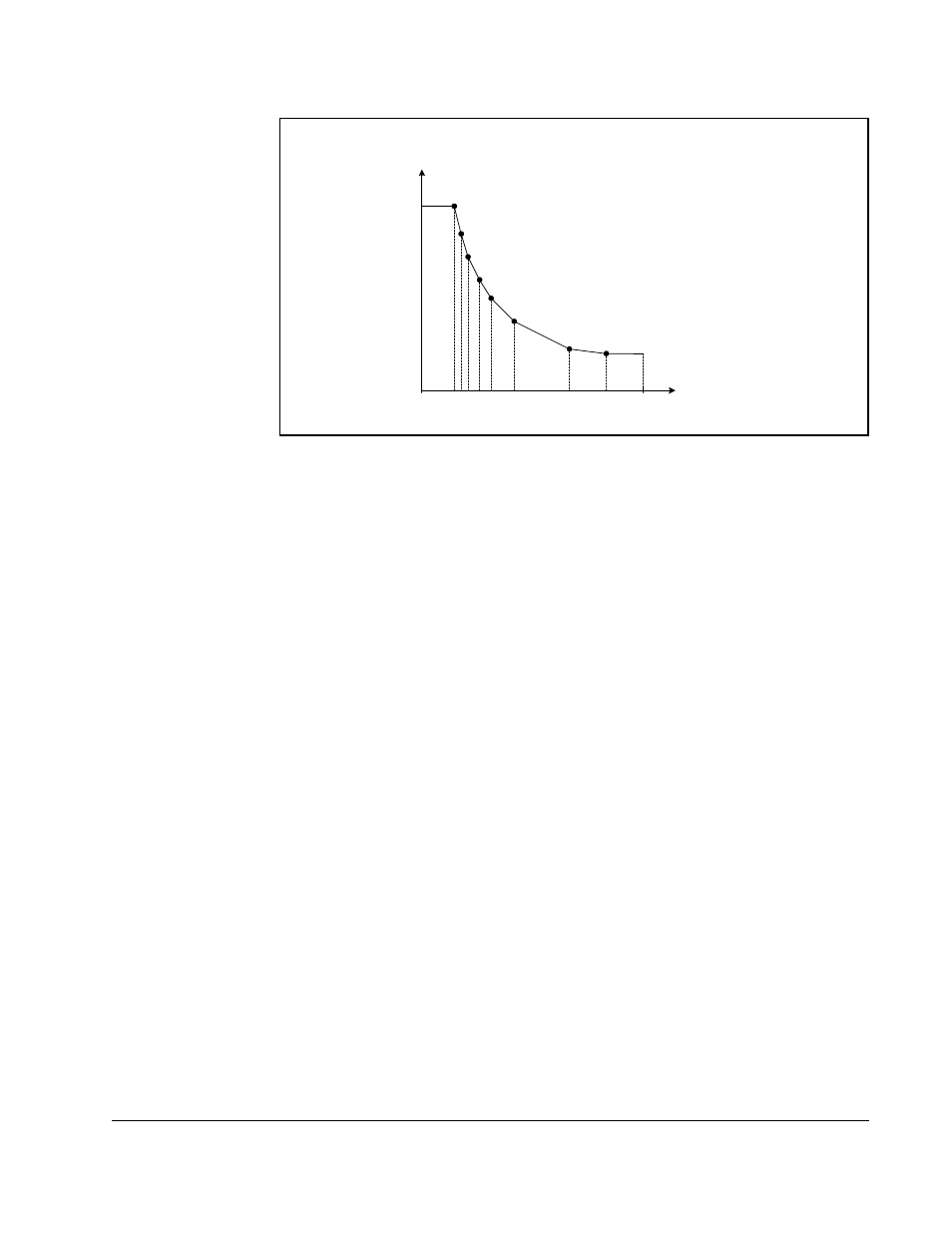

Figure A.1 – Typical Type 2 Field Reference Curve

F I E L D I N P U T n

Field

Current

1

2

3

4

5

6

7

8

Motor RPM or

Roll Diameter

FIELD CURRENT n

GEAR IN

SPEED

0