2 the, Block, 3 the tension loop – Rockwell Automation WebPak 3000 DC Drive Application Workbook Version 1.1 User Manual

Page 71

Configuring the Tension Outer Control Loop

12-3

12.1.2 The

LEAD

/

LAG

Block

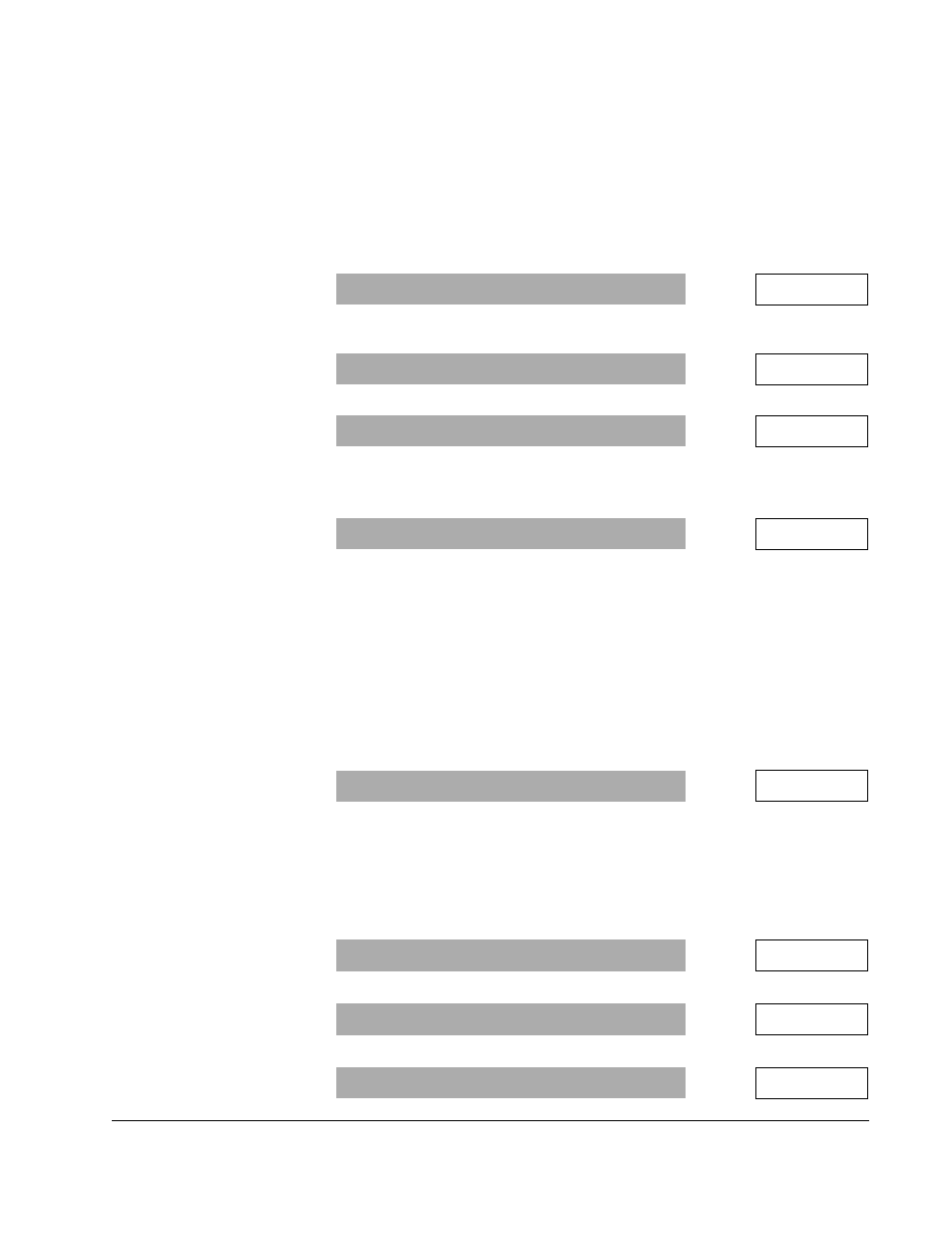

The tension feedback signal is also conditioned by a

LEAD

/

LAG

block, which is set to

approximately cancel the lag attributable to the speed loop bandwidth. Refer to figure

A.18 in Appendix A of the software manual (D2-3444).

þ

To set up the

LEAD

/

LAG

block:

▲

Set

TEN

FDBK

LL

BYPASS

(P.845) to

OFF

.

▲

Set

TEN

FDBK

LL

LOW

FREQ

(P.835) to the same value as

SPEED

CROSS

OVER

(P.133).

▲

Set

TEN

FDBK

LL

RATIO

(P.836) to 7.5.

þ

To bypass the

LEAD

/

LAG

block:

▲

Set

TEN

FDBK

LL

BYPASS

(P.845) to

ON

.

12.1.3 The Tension Loop

PI

Block

Refer to figure A.19 in Appendix A of the software manual (D2-3444) as you configure

the tension loop

PI

block.

The input to the tension loop

PI

block is

TEN

LOOP

ERROR

(P.834), which is a read-only

parameter.

þ

To set the

PI

block integral gain:

▲

Set

TEN

PI

LEAD

FREQ

(P.840) to 0.2 radians/second.

þ

If the drive is a variable diameter section:

▲

Tune the proportional gain at empty core diameter.

þ

To set the

PI

block proportional gain,

TEN

PI

PROP

GAIN

(P.841):

▲

Set

TEN

PROFILER

ENABLE

(P.878) to

DISABLE

.

▲

Set

OCL

TYPE

(P.818) to

CASCADE

.

▲

Set

OCL

SELECT

(P.817) to

TENSION

.

Range:

OFF

,

ON

P.845 =

2))

Range: 0.01 to 34.90

RAD

/

S

P.835 =

RAD

/

S

Range: 2 to 20

P.836 =

Range:

OFF

,

ON

P.845 =

21

Range: 0.00 to 141.37

RAD

/

S

P.840 =

5$'6

Range:

ENABLE

,

DISABLE

P.878 =

',6$%/(

Range:

CASCADE

,

PARALLEL

P.818 =

&$6&$'(

Range:

NONE

,

TENSION

,

CURRENT

,

POSITION

P.817 =

7(16,21