The diameter calculator, 2 the diameter calculator – Rockwell Automation WebPak 3000 DC Drive Application Workbook Version 1.1 User Manual

Page 42

6-2

WebPak 3000 DC Drive Application Workbook, Version 1.1

▲

Set

DIAMETER

UPDATE

RATE

(P.867) to specify the number of roll revolutions

between diameter updates. This is based on web thickness. Typically, thinner

webs use a higher update number.

þ

For variable diameter applications (unwinds or winders),

GEAR

IN

SPEED

(P.011) is the motor speed at

TOP

LINE

SPEED

(P.020) and

EMPTY

CORE

DIAMETER

(P.830):

▲

Set

EMPTY

CORE

DIAMETER

(P.830).

6.2

The Diameter Calculator

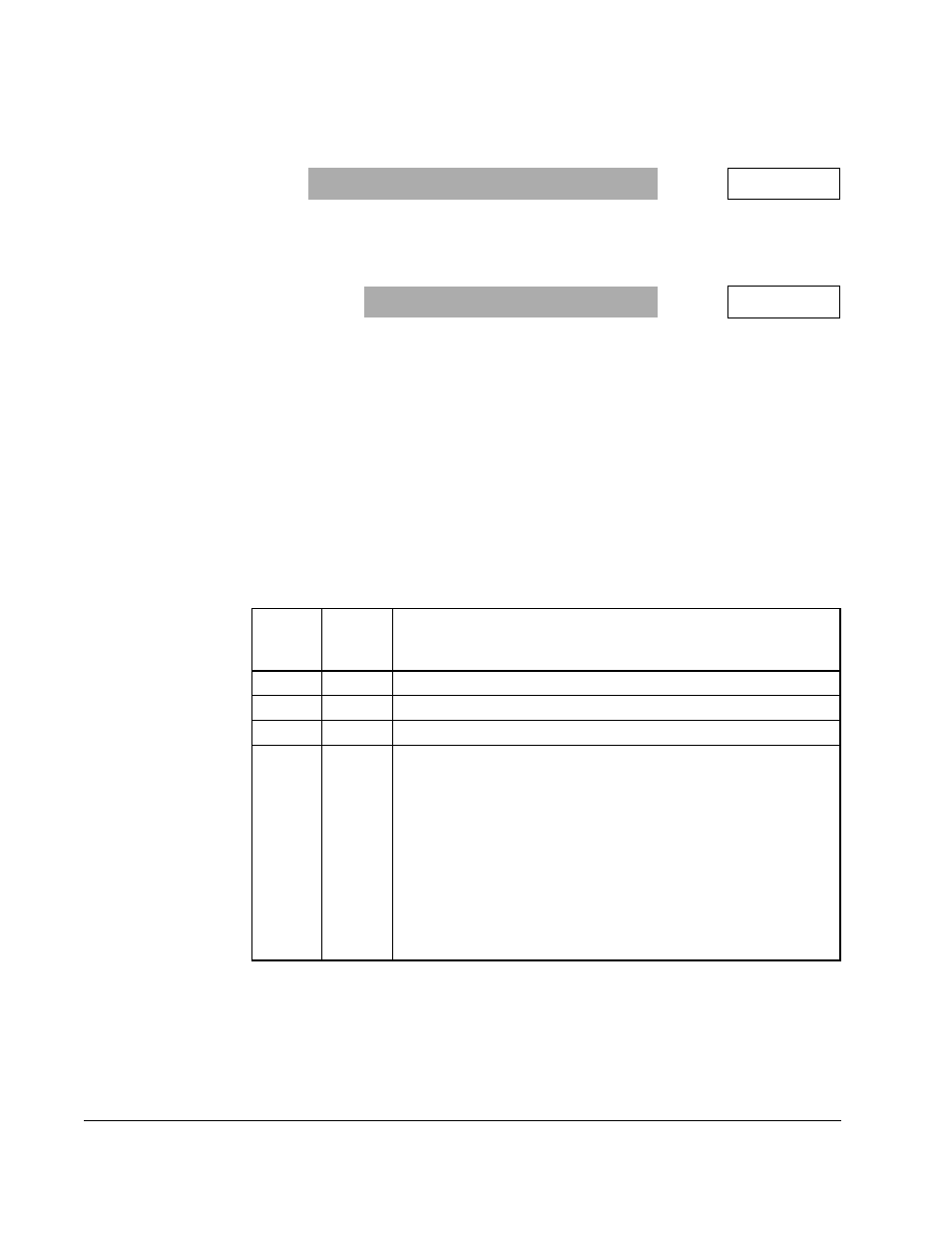

Six of the inputs to the diameter calculator function block are calculated by the system:

•

The absolute value of

SPEED

RAMP

OUTPUT

(P.199).

•

The absolute value of

SPD

LOOP

FEEDBACK

(P.296).

•

The output of the threshold function block.

•

A reset diameter value determined by the status of digital input

DIAMETER

SELECT

A

TP

(P.495) (terminal 59 on the I/O Expansion board) and digital input

DIAMETER

SELECT

B

TP

(P.496) (terminal 60 on the I/O Expansion board) as shown in the

following table. P.495 and P.496 can also be asserted over the network when a

network card is installed.

•

DIAMETER

/

TAPER

IN

TP

(P.192), which is the value in counts of the input after gain and

zero have been applied.

•

DIAMETER

RESET

TP

(P.829) will reset the diameter calculator to a diameter based on

the status of

DIAMETER

SELECT

A

TP

(P.495) and

DIAMETER

SELECT

B

TP

(P.496). P.829

is on when digital input 62 on the I/O Expansion board is on provided that

DIAMETER

RST

DIN

TP

(P.497) is asserted.

Range: 1 to 10

REVOLUTIONS

P.867 =

REV

Range: 1.00 to 30.00

INCHES

P.830 =

INCHES

Status

Input A

(P.495)

Status

Input B

(P.496)

Reset Diameter Value

ON

OFF

WINDER

CORE

DIA

1 (P.822)

OFF

ON

WINDER

CORE

DIA

2 (P.824)

ON

ON

WINDER

CORE

DIA

3 (P.825)

OFF

OFF

UNWIND

DIAMETER

IN

(P.828) which is the analog signal of the

analog input diameter/taper (terminals 16, 17, and 18 on the

Regulator board) when

DIAMETER

/

TAPER

SELECT

(P.870) is set to

DIAMETER

.

Important: Note that the analog signal will be maximum at

core diameter and minimum at full roll diameter.

This is consistent with the output characteristics of

a sonic roll diameter detector. When a

potentiometer is used to set diameter, the

connections should reflect maximum volts at core

and minimum volts at full roll.