Rockwell Automation WebPak 3000 DC Drive Application Workbook Version 1.1 User Manual

Page 21

Configuring the Speed Loop

3-11

þ

To select the outer control loop proportional trim operation:

The value of the outer control loop

PI

limits is set proportional to the absolute value

of

SPEED

RAMP

OUTPUT

(P.199). This keeps the gain of the outer control loop

constant at all line speed operating levels.

A

SCALE

block is used to establish the range of the outer control loop percent

control. The output of the

SCALE

block will be a number that will change linearly

from the value of

OCL

PROP

TRIM

GAIN

(P.812) to 1.0 as

SPEED

RAMP

OUTPUT

(P.199)

changes from its minimum value of zero to

TOP

LINE

SPEED

(P.020).

When P.812 is set at its default value of 1.0, the outer control loop

PI

limit will be a

fixed percentage of

TOP

LINE

SPEED

(P.020); but as line speed is decreased, the

limit will increase proportionately as shown in figure 3.1.

▲

Set

OCL

PROP

TRIM

GAIN

(P.812). The minimum value of P.812 should be set at

0.05 so that a minimum speed loop reference is available for stall tension

operation.

▲

Set

OCL

INVERT

ENABLE

(P.815) to specify the polarity of the outer control loop.

The location of a drive’s outer loop control zone in a process line may be

upstream or downstream of the lead section; therefore, the polarity of the

outer control loop needs to be set accordingly.

ENABLE

: The

OCL

signal is subtracted from the speed loop reference.

DISABLE

: The

OCL

signal is added to the speed loop reference.

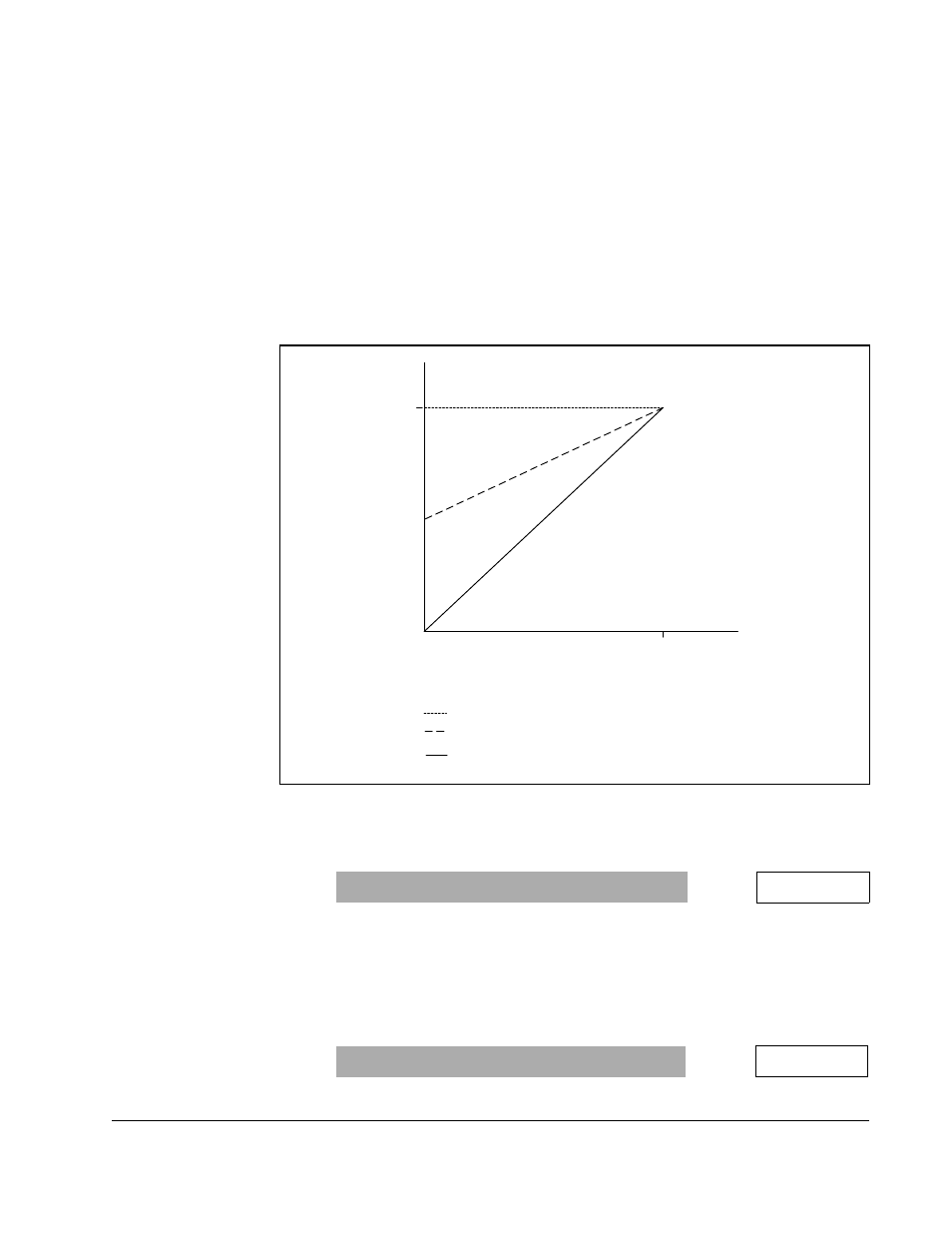

Figure 3.1 – Outer Control Loop Proportional Trim

Range: 0 to 1.000

P.812 =

Range:

ENABLE

,

DISABLE

P.815 =

O u t e r L o o p

PI Limit

S p e e d

O C L

P R O P

T R I M

G A I N

(P.812) = 1.0

O C L

P R O P

T R I M

G A I N

(P.812) >0.0<1.0

O C L

P R O P

T R I M

G A I N

(P.812) = 0.0

Curve 1

1

2

3

M a x i m u m P I

Limit

T o p L i n e S p e e d

Curve 2

Curve 3