5 controlling the spc200 via the profibus, Controlling the spc200 via the profibus – Festo Кабели и принадлежности User Manual

Page 26

1. System summary

1−8

Festo P.BE−SPC200−COM−PDP−E N en 0901c

1.5

Controlling the SPC200 via the PROFIBUS

The usual I/O signals (START, STOP, RESET, etc.) are available

via PROFIBUS, exactly as with direct control of the SPC200 via

an I/O module. If required, the field bus module can also enĆ

able the transmission of parameters and actual positions.

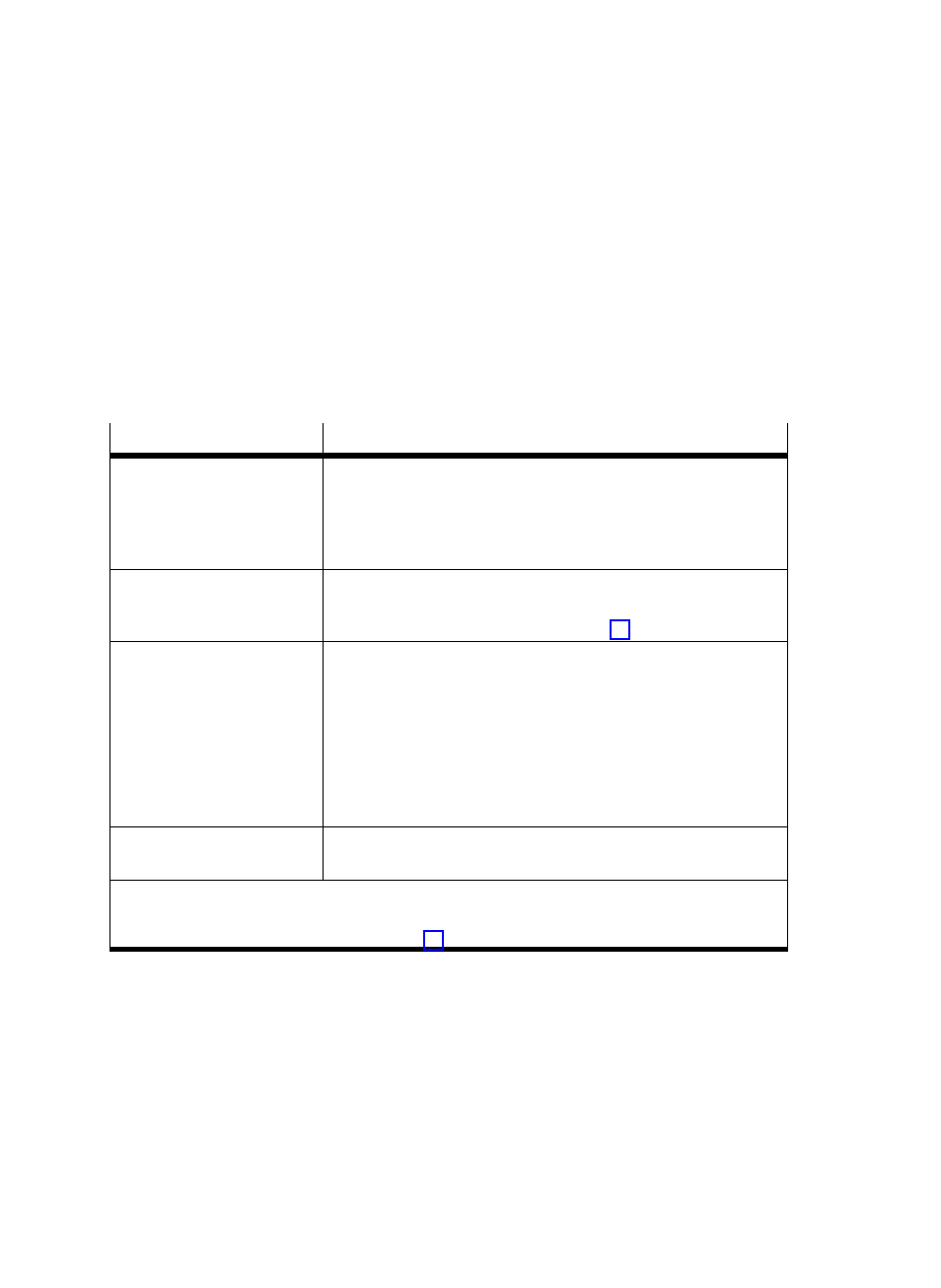

Function

Description

Ĉ I/O signals

For transmitting the I/O control signals and the freely programmable

I/Os (Start/Stop mode) or the record number (Record Select mode),

the field bus module offers the following inputs/outputs:

Ĉ Inputs: I10.0 ... I13.15

1)

Ĉ Outputs:Q10.0 ... Q13.15

1)

Ĉ Parameter channel

(optional)

By means of a parameter channel, operands such as flags, position

registers, digital outputs etc. as well as the desired positioning

behaviour can be parametrized (see section 5.2).

Ĉ Setpoint positions

(optional)

The nominal positions can be transmitted from the PROFIBUS−DP

master in the task telegram.

2)

With this is, using the NC command M10 (see system manual on the

SPC200), the digital nominal value specification possible.

Prerequesits:

Ĉ WinPISA as from Version 4.41

Ĉ fieldbus modules for PROFIBUS−DP with firmware version as from

V 2.1

Ĉ SPC200 with operating system version as from V 4.82.

Ĉ Actual positions

(optional)

The actual positions can be transmitted to the PROFIBUS−DP master

in the reply telegram.

2)

1)

Address assignment from the point of view of the SPC200

2)

The telegram which the master sends to the slave is called the task telegram. The reply from the

slave is called the reply telegram, see section 4.4.2.