KROHNE OPTIMASS with MFC 300 EN User Manual

Page 53

53

Important:

Always heat the jacket to working temperature before flowing product through the measuring

tube.

Avoid the use of fluids that can cause crevice corrosion.

Although all the jacket materials are 316L, the outer cylinders are 304L (Optional 316L).

Connections should be made to ensure all air can be vented on liquid systems and all conden-

sate can be drained on steam systems.

Note :

The maximum heating medium pressure and temperature for heating jackets is 10 barg at

150°C (145 psig at 300°F) for titanium measuring tubes and 10 barg at 100°C (145 psig at 210

°F) for Hastelloy, Stainless Steel and Tantalum measuring tubes.

Heating Times:

The following graphs are provided as a guide only. Heating times were calculated and tested

using the following conditions:

•

Ambient temperature 25°C (80°F)

•

Meter insulated.

The Titanium meters were heated using a steam temperature of 150°C (302°F) and the

Hastelloy and Stainless Steel meters using a temperature of 100°C (212°F).

Heating times may vary depending on the quality of insulation (if any), ambient temperature

and temperature of the heating medium. Once the meter has been heated to a temperature

where the product will not solidify, the product may be introduced if required. This will bring

the meter to operating temperature sooner.

Note:

The maximum heating temperature for a Titanium meter is 150°C (300°F).

The maximum heating temperature for Hastelloy or SS meters is 100°C (212°F).

If these temperatures are exceeded, the meter will be damaged.

KROHNE accepts no responsibility if this happens.

For information regarding Tantalum heating temperature, please contact Krohne

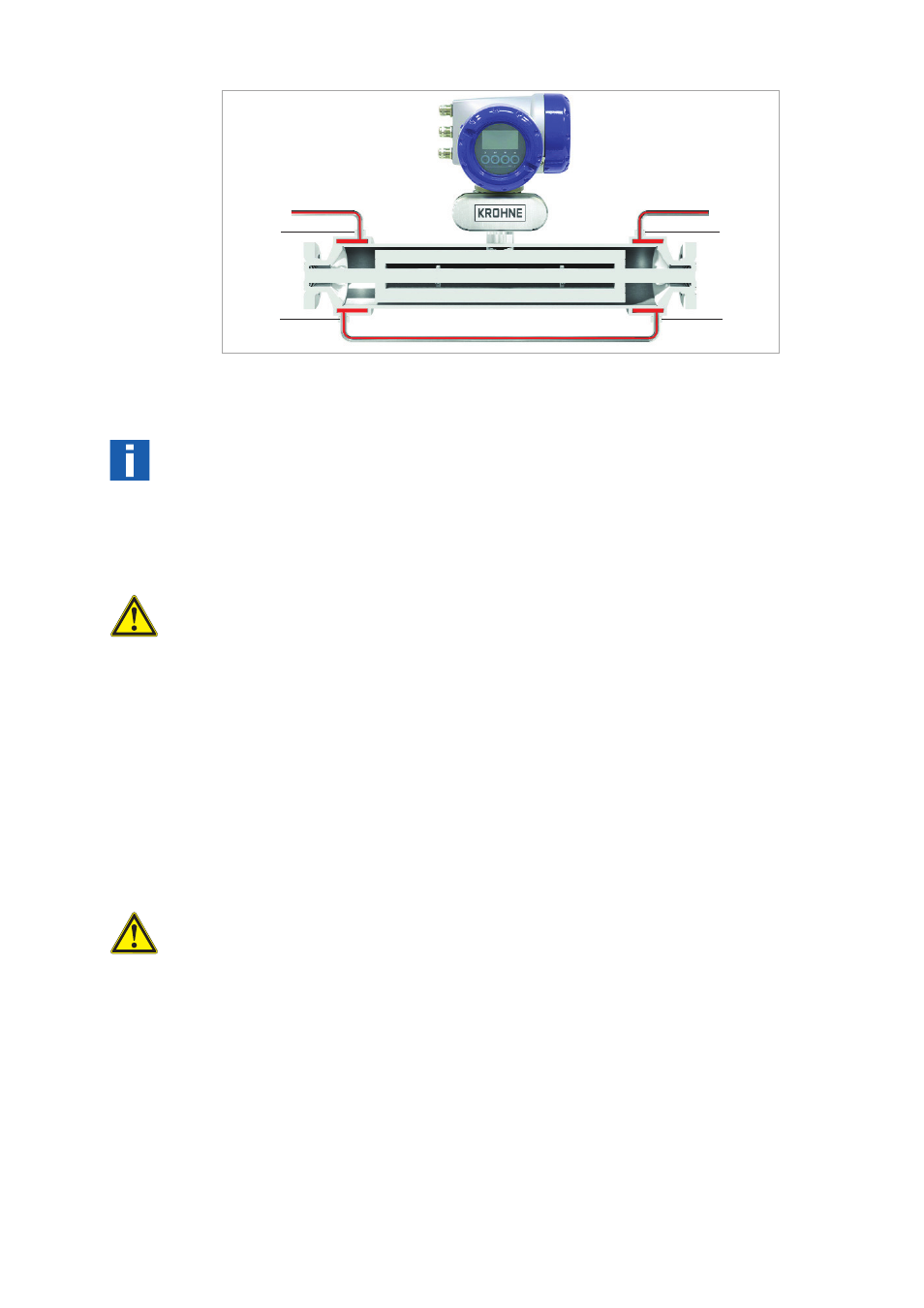

1 2 3 4

Connection Points

1

2

4

3