KROHNE OPTIMASS with MFC 300 EN User Manual

Page 119

119

Zero Calibration (Menu C1.1.1)

Following checks on the installation for soundness, it is necessary to set the zero point on the

meter prior to use.

All modifications/adjustments to the installation MUST be completed before the zero point is

set. Any modifications or changes (to piping or calibration factor) carried out after the zero

point has been set will render the performance of the meter unreliable and therefore will

require the zero point to be reset.

To achieve a successful zero calibration the following points MUST be noted:

•

The primary head should be completely full of process fluid at normal operating pressures

and temperatures.

•

All air MUST be exluded from the fluid, particularly for horizontal installations. It is recom-

mended that the primary head be flushed with the process fluid at a high flow rate (>50%),

for 2 minutes, prior to starting the adjustment.

•

After flushing, flow in the primary head MUST be brought back to zero by tightly closing

appropriate valves.

The zero off-set can either be measured automatically or entered manually using the display

keys. If an automatic adjustment is to be made then the operator should trigger this, with the

front cover still in place.

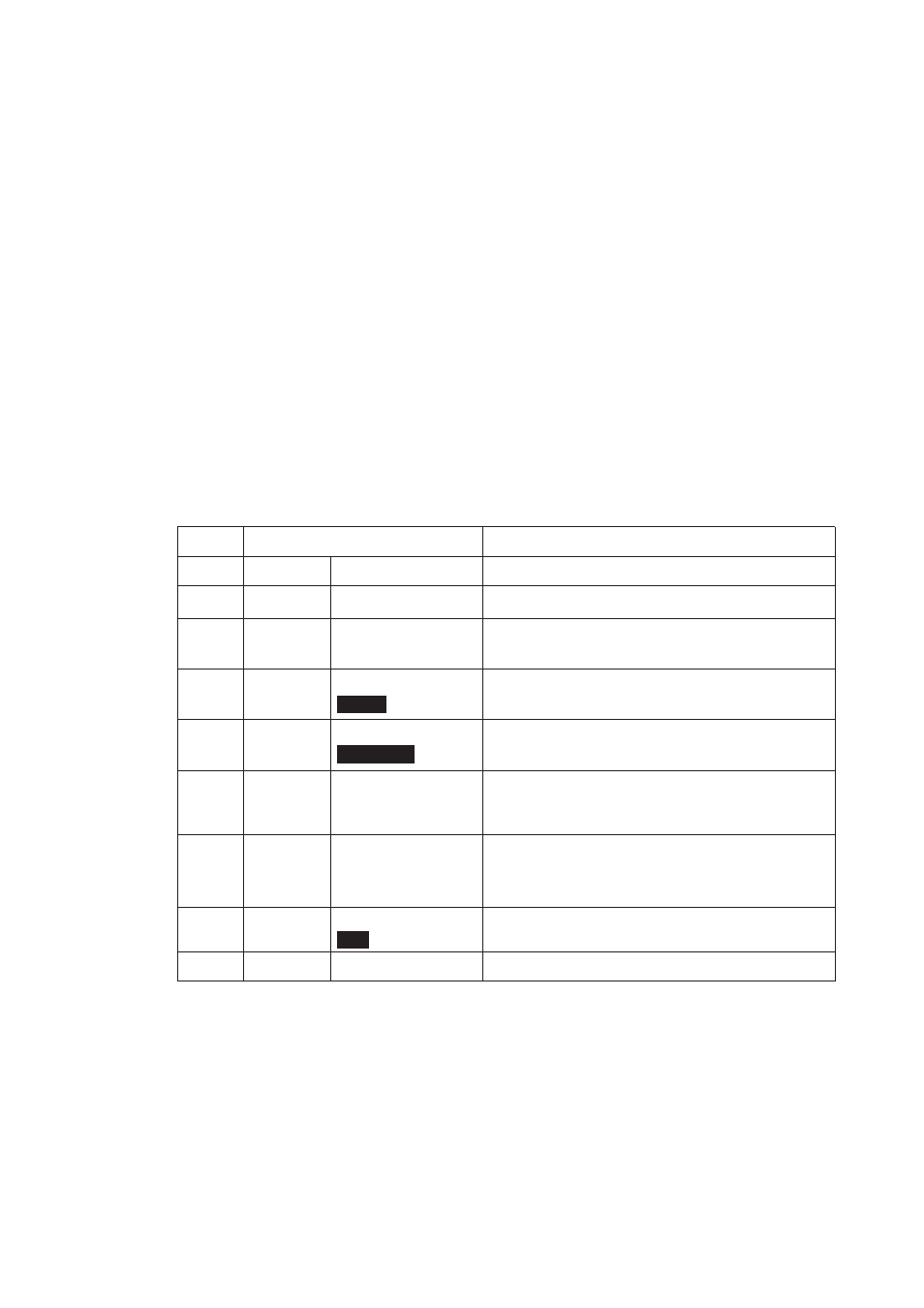

A) Automatic Adjustment:

Key

Text Displayed

Description

>

A

Quick Setup

Countdown from 2.5 s to 0.0 s, then release key

C

Setup

> > >

C1.1.1

Zero Calibration

>

Calibrate Zero?

Break

Calibrate Zero?

Automatic

g

Please Wait

Countdown from 32s

Zero Calibration

+XX.XXX%

Displays zero value in %

Note: Care MUST be taken as the value can be

edited!

g

x 5

Save Configuration?

Yes

Accept Zero

g

Measuring Page

Automatic

Yes

Break