3 pressure equipment directive (ped) requirements, 2 ambient / process temperatures – KROHNE OPTIMASS with MFC 300 EN User Manual

Page 38

38

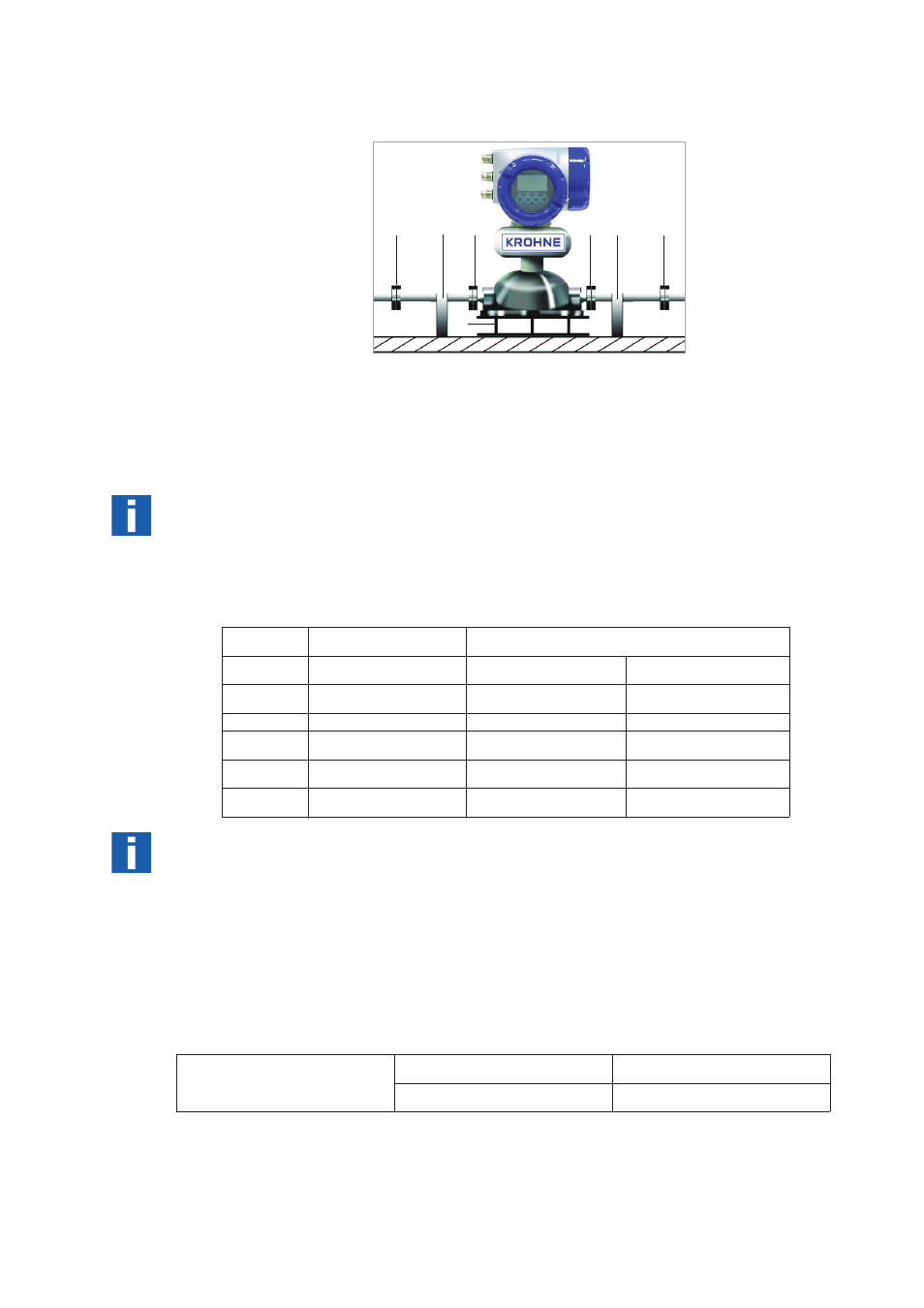

Flanged and Tri-clamp Meters

When installing these meters ensure that the pipework is supported behind the process , so

that no unnecessary stress is applied to the meter flanges.

Note:

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

Where meters are mounted in direct sunlight, it is recommended to install a sunshade. This is

particularly important in countries with high ambient temperatures.

6.3 Pressure Equipment Directive (PED) requirements.

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter.

Measuring tube:

S

Stainless SS 316 L

H

Hastelloy C22

The outer casing (Secondary Pressure containment) is 316L

Wiring feedthrough is made of epoxy with ‘0’ ring seals in FPM / FKM and hydrogenated nitrile.

Connections are all 316 / 316 L dual certified or Hastelloy C22

The optional heating jacket is 316 or 316L.

1

Fix meter to a firm support

2

Carefully align the process flanges and connect

3

Support the process pipe close to the flanges. Do not pull pipe with clamps!

4

Make the final process connections. If there are no connections in this area, try to have

some flexibility in the process pipe

Note:

Please note that gas bubbles can also accumulate between flange and measuring tube due to

the step change, mount vertically to avoid this.

6.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

SS316L or HC22

°C

°F

Process

-40 ... +150

-40 ... +300

Ambient

Compact Aluminium

-40 ... +60

-40 ... +140

Compact Stainless

-40 ... +55

-40 ... +130

Remote

-40 ... +60

-40 ... +140

4

4

3

1

3

2

2