Optimass 2000, 3 pressure equipment directive (ped) requirements, 1 specific installation guidelines – KROHNE OPTIMASS with MFC 300 EN User Manual

Page 25: 2 ambient / process temperatures

25

OPTIMASS

5

OPTIMASS 2000

Note:

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

Where meters are mounted in direct sunlight, it is recommended to install a sunshade that

covers the converter and front end. This is particularly important in countries with high ambi-

ent temperatures.

The maximum differential temperature between the process and ambient temperature without

insulation is 110°C or 200°F.

To avoid thermal shock, the meter MUST NOT be subject to rapid changes in process tempra-

tures and reference should be made to the following table

Operation outside these limits may result in shifts in density and mass flow calibration.

Repeated shocking may also lead to premature failure of the meter! However, higher thermal

shocks are possible at lower working presures. Please consult Krohne for more information.

5.3 Pressure Equipment Directive (PED) requirements

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter:

Measuring tube:

Spigots

Stainless Steel UNS 531803

Stainless Steel UNS J902205

The outer cylinder 304 / 304L is dual certified (Optional outer cylinder of 316 / 316L).

Wiring feedthrough is made of Epoxy (or PEEK) with 2 ‘O’ ring seals in Fpm / fkm &

Hydrogenated Nitrile.

5.1 Specific Installation Guidelines

•

Tighten flange bolts evenly.

•

Observe the pipe end loads as shown in S.5.6

•

It is permissible to support the weight of the meter on the body.

•

Use of standard pipework reducers at the flange is allowed. Avoid extreme changes in pipe

size (step changes).

•

The use of flexible hoses for connection to the process pipework is NOT recommended.

•

The meter can be installed so that the converter is on the side of the meter, resulting in the

measuring tubes on top of each other, unless gases or solids are being measured.

•

The 2000 series has exceptional immunity to cross-talk, therefore allowing meters to be

used in series or parallel

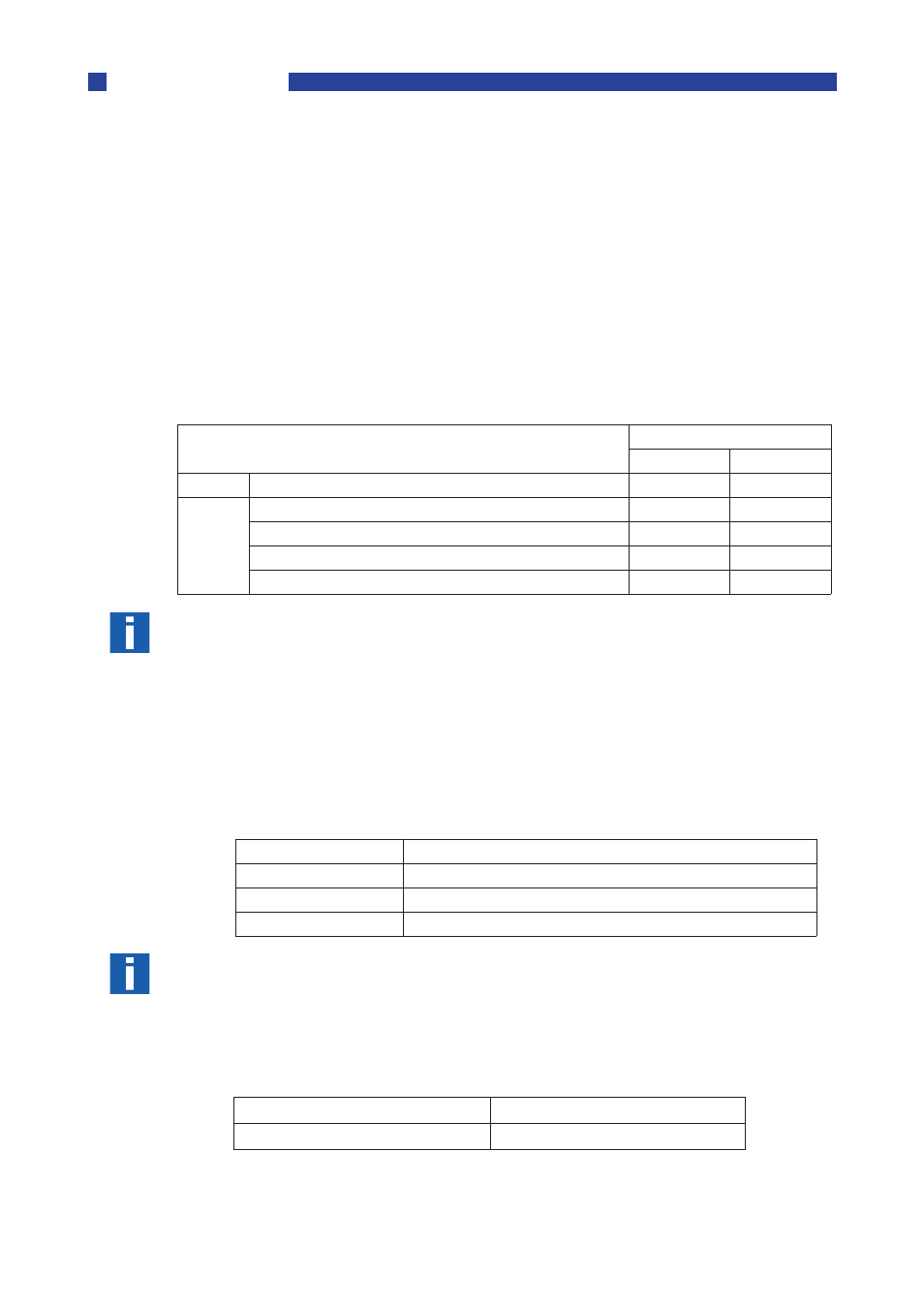

5.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

Meter

Max. Temperature Shift

S100

90°C (110°C with a max operating pressure of 40 barg)

S150

80°C

S250

50°C

SS318L

°C

°F

Process

All meters

-45...+130

-49...266

Ambient

Compact Al.

-40...+60

40...+140

Compact Al. with certain I/O options (consult Krohne)

-40...+65

-40...+149

Compact SS

-40...+55

-40...+131

Remote

-40...+65

-40...+149