4 secondary pressure containment, 5 hygienic applications – KROHNE OPTIMASS with MFC 300 EN User Manual

Page 13

13

Flanges all 316 / 316 L dual certified.

Hygienic Connections are 316L

Optional heating jacket 316 / 316L

Note: Outer cylinder is in contact with heating medium

4.4 Secondary Pressure containment

The OPTIMASS 1000 meters are supplied (as standard) without certified housings that have a

typical burst pressure

>

100 barg.

Options are available with PED certified housings, with the following pressure ratings:

304/304L and 316/316L: 63 bar @20°C 580 psi @ 68°F

316/316L: 100 bar @20°C 1450 psi @ 68°F

If the user suspects that the primary tube has failed, the unit must be depressurised and

removed from service as soon as it is safe to do so.

Note:

In the 1000 series there is a high pressure wire feed through with ‘O’ rings that might not be

compatible with the process fluid for an extended period if a primary tube fails.

It is the user’s responsibility to ensure that the materials used are compatible with this prod-

uct.

Other ‘O’ ring materials are available on request.

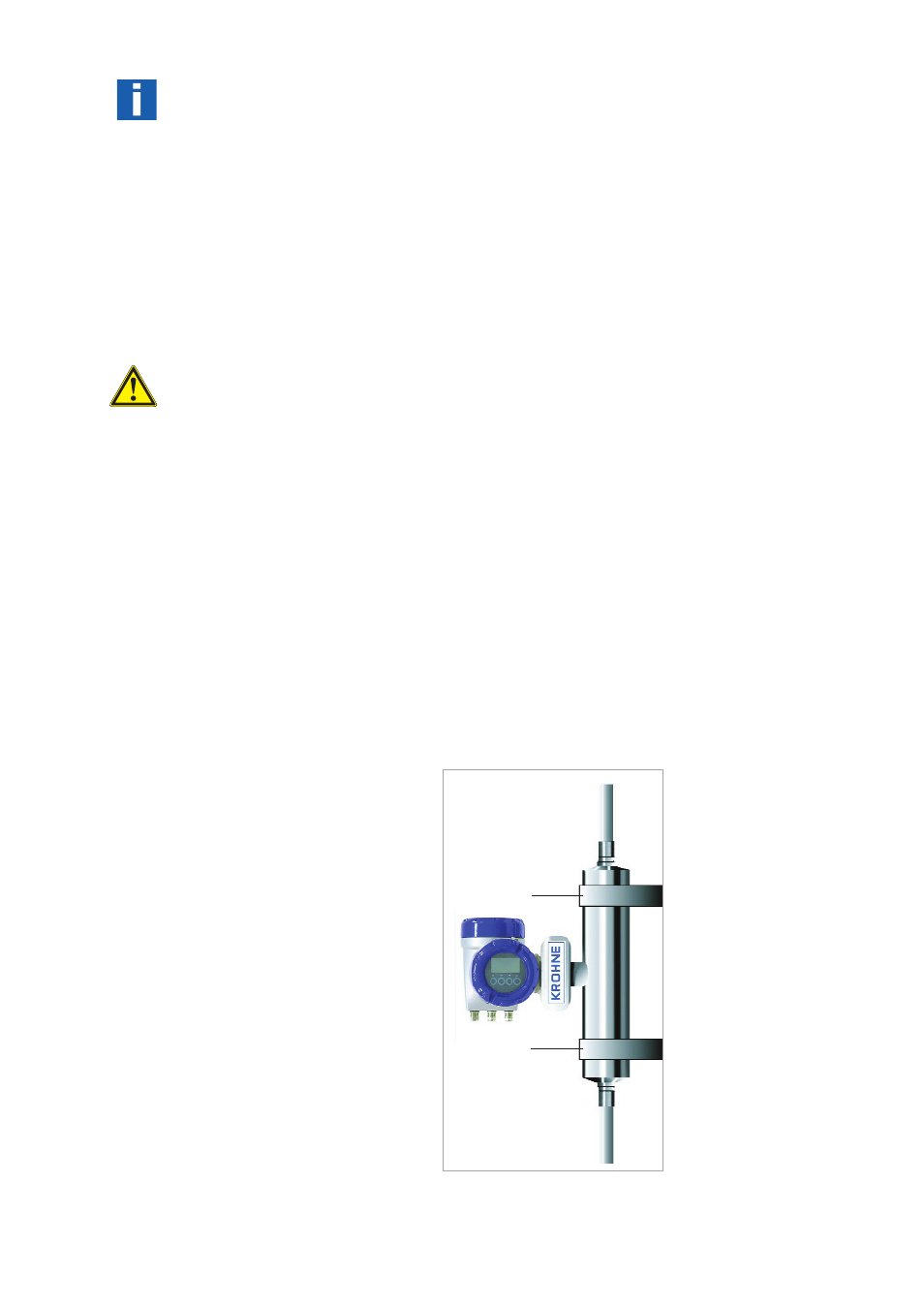

4.5 Hygienic Applications

The OPTIMASS 1000 series is available with a variety of hygienic process connectors.

When installing / using meters with hygienic process connectors, support /clamp the meter

properly. The meters are heavy and could injure when disconnected from the adjacent pipe

work.

The recommended method of installation is to mount the meter against a support / wall with

the body of the meter supported / clamped. The process pipe work can then be supported off

the meter. The meter is too heavy to be supported from the thin walled piping usually associ-

ated with the hygienic industry

1 2

Meter Supports

1

2