6 pressure ratings – KROHNE OPTIMASS with MFC 300 EN User Manual

Page 14

14

These loads are roughly equivalent to the max axial loading allowed in an un-radiographed butt

weld in a 316L schedule 40 pipe.

Loads given are maximum static loads. If loads are cycling, particularly between tension and

compression, these loads should be reduced.

Please consult KROHNE for more information.

The 3A approval for the 1000 series requires that it is “self draining”. Install the meter vertical-

ly with the flow running uphill.

Installation lengths

For installation lengths, please see section 4.9

Please check with KROHNE if you are unsure of the installation length. Many meters are built

to customer requirements / specifications especially where special hygienic process nectors

have been adapted to the meter. As these are normally non-standard, the installation length

will not be given in the technical data

It is also recommended that the seals be replaced regularly to maintain the hygienic integrity

of the connection.

Unless specifically requested, internal surfaces are not polished and no warranty is made as to

the surface finish.

If polishing option and /or EHEDG, ASME Bio-Processing or 3A approvals was selected at time

of order, all product contact surfaces are polished 0.5 micrometer Ra (20CLa) finish or better.

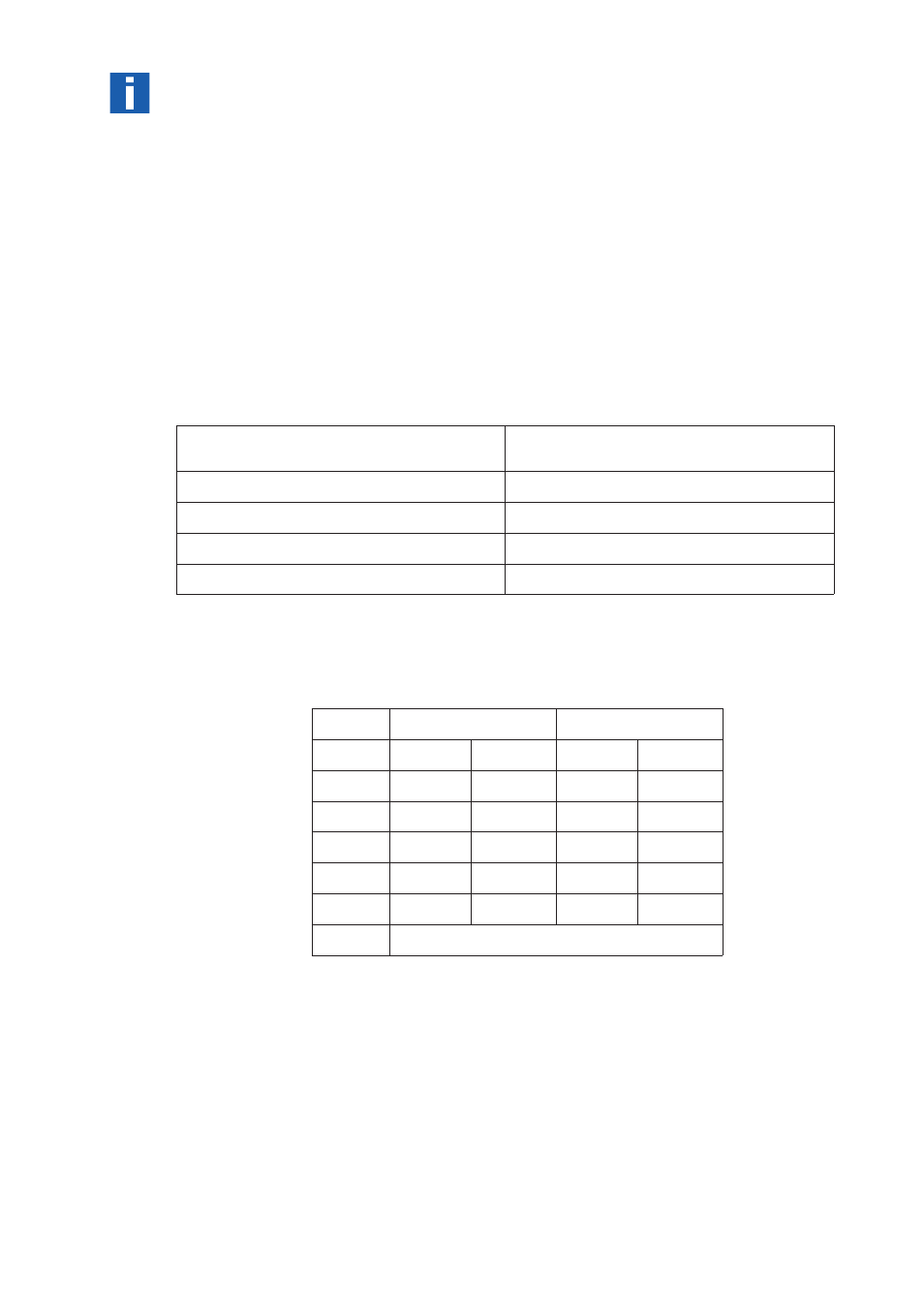

4.6 Pressure ratings

Meter data plates are stamped with maximum pressure rating at both 20°C (68°F) and max.

operating temperature of connection, primary tube or secondary pressure containment

whichever is the lower.

Maximum pipe work forces

Tubes and secondary

pressure containment 100 barg

100 bar at 20°C (1450 psi at 68°F)

De-rated to

80 bar at 130°C (1160 psi at 266°F)

Heating Jacket

10 bar at 130°C (145 psi at 266°F)

Secondary pressure containment 63 barg

63 bar at 20°C (914 psi at 68°F)

De-rated to

50 bar at 130°C (725 psi at 266°F)

20°C

130°C

40 bar

100 bar

32 bar

80 bar

Size

Max Load

Max Load

Max Load

Max Load

15

25 kN

17 kN

18 kN

12 kN

25

38 kN

19 kN

28 kN

12 kN

40

48 kN

15 kN

35 kN

7 kN

50

99 kN

20 kN

72 kN

8 kN

Flange Connections