KROHNE OPTIMASS with MFC 300 EN User Manual

Page 30

30

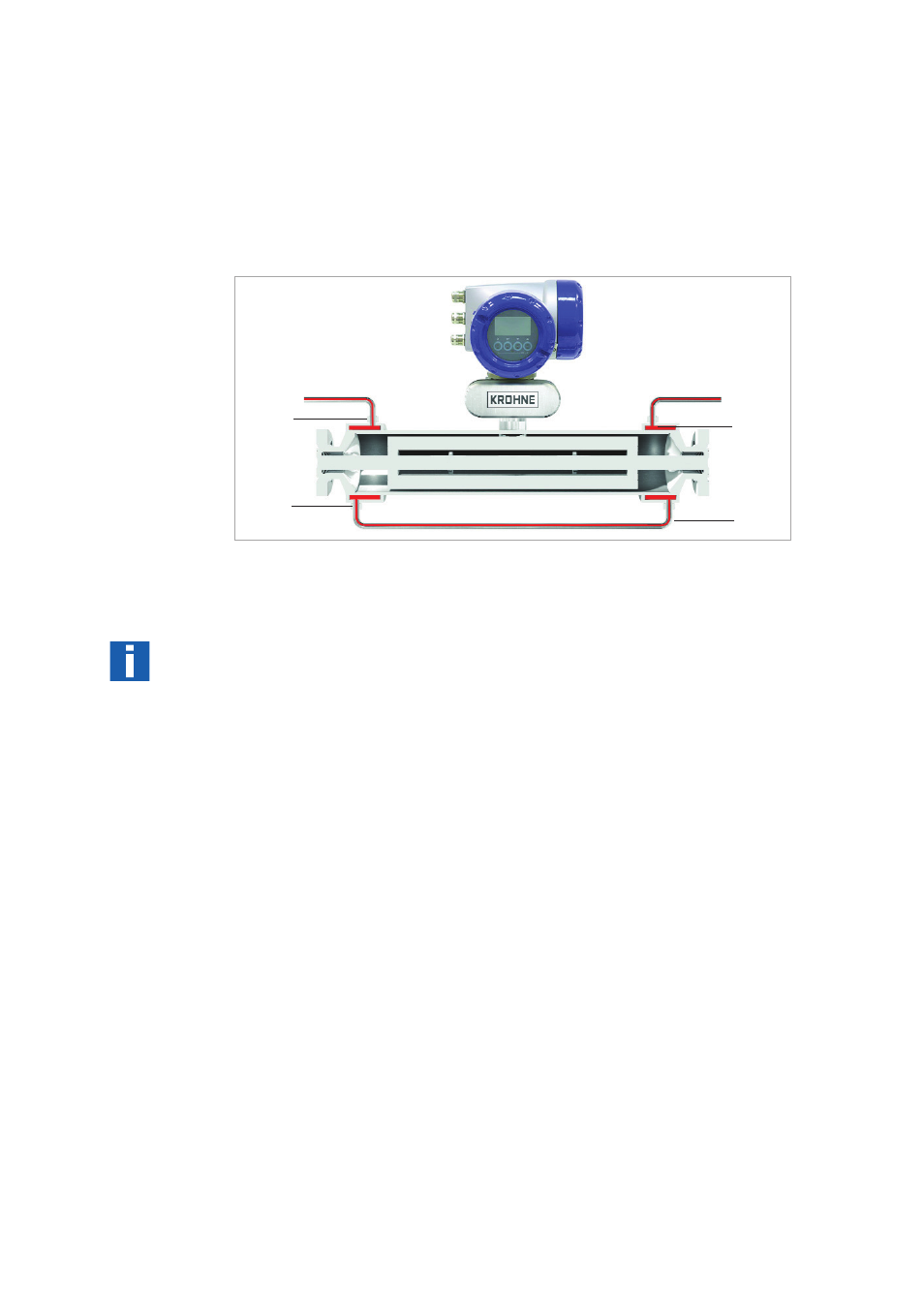

Liquid / Steam heating jacket

The meter can be supplied with a heating jacket. This jacket is designed to minimise the differ-

ential stress across the meter where differences in temperature between outer cylinder and

measuring tube exist.

The connections to the heating jacket are NPT or Ermeto sockets.

It is recommended that reinforced flexible hoses be used to connect the heating jacket to the

heat source.

1

2

4

3

1 2 3 4

Connection Points

Important:

Always heat the jacket to working temperature before flowing product in measuring tube.

Avoid the use of fluids that can cause crevice corrosion.

Although all the jacket materials are 316L, the outer cylinders are 304L (Optional 316L).

Connections should be made to ensure all air can be vented on liquid systems and all conden-

sate can be drained on steam systems.

Note :

Max heating medium pressure and temperature for heating jackets is 10 bar at 130°C or 145

psig at 266°F.

Heating Times

The heating times shown in the following illustrations are based on the heating jacket operat-

ing at maximum temperature and show the measured temperatures at the spigot end of the

measuring tubes. If a desired temperature is required in the centre of the measuring tubes,

then the heating times MUST be extended.