KROHNE OPTIMASS with MFC 300 EN User Manual

Page 140

140

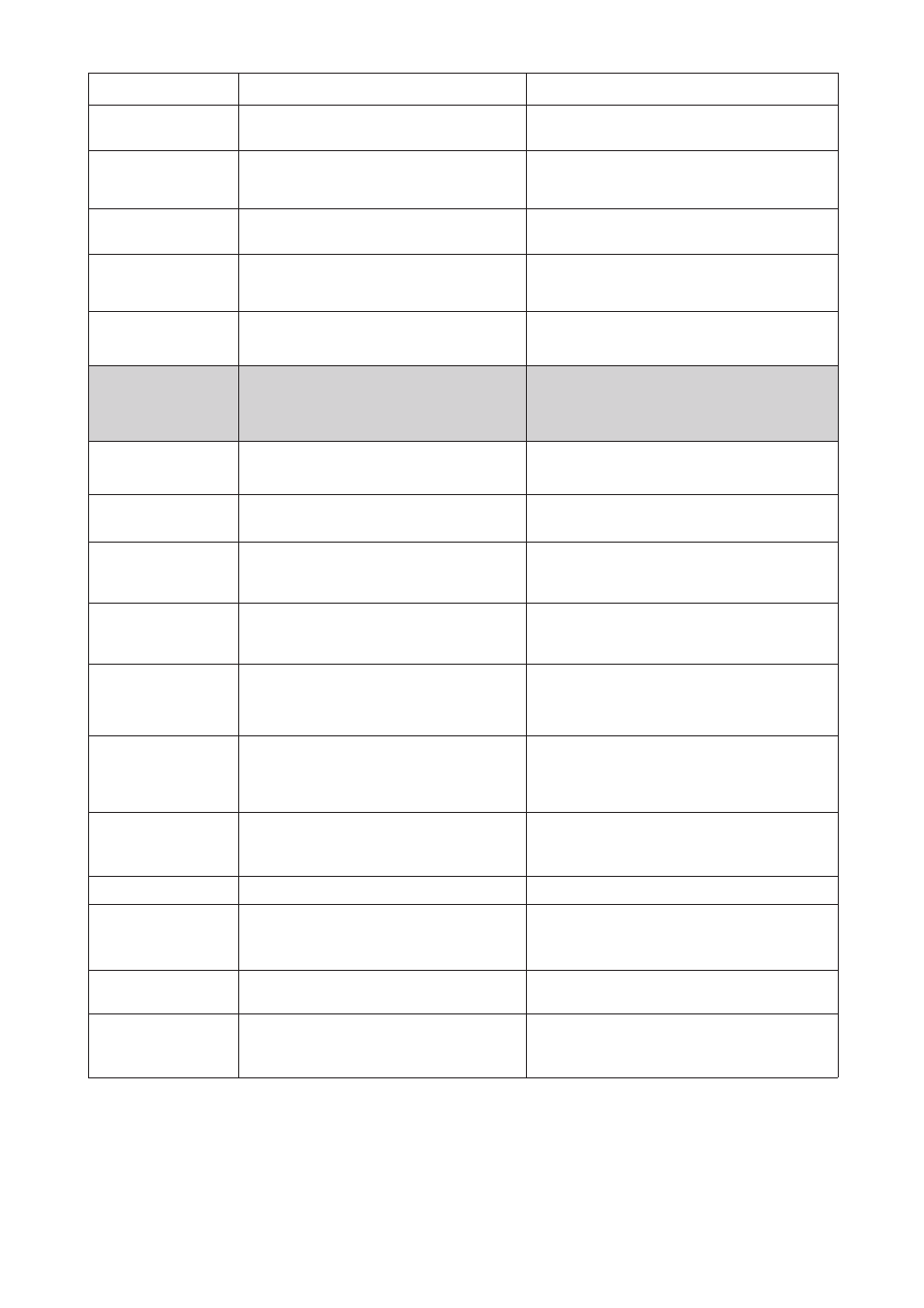

Display Messages

Description

Possible causes, remedial action

SE Data Different

Sensor electronics configuration does

not match MFC300

Sensor or converter has been changed. See

section 11.4.

COMM FAIL

Communications failure with the sensor

electronics. Measurement data not

available

Check wiring. Check grounding.

Replace electronics

Active settings

Fault detected during CRC check of

active settings

Upload Backup 1 or Backup 2 settings,

check and adjust if necessary.

Factory settings

Fault detected during CRC check of fac-

tory settings

Backup 1 / 2 set-

tings

Fault detected during CRC check of

Backup 1 / 2 settings

Store active settings in Backusp 1 / 2.

Status: S _ _ _ _

Out of specification,

Measurement continues but measured

values are uncertain

Maintenance necessary!

Out of specification

Out of specification: measurement con-

tinues with less accuracy

Group message, when faults as below or

other influences occur.

Overflow, counter

1/2/3

Counter has overrun and started again

at zero.

Check counter format

Backplane invalid

The data record on the backplane is

invalid. The CRC check has revealed a

fault.

Save data again to backplane (Service)

SE PCB

Temperature

Temperature on SE PCB is exceeding

maximum limit

Check process & ambient temperature.

Check wiring.

Replace sensor electronics

Start Up

Sensor is in start up phase

Check process conditions (air)

Check meter settings C1.7.1 to C1.7.3

Check sensor resistances

Power Fail

For custody transfer application.

Indicates a failure of power supply. No

measurement is possible during power

failure

Tube Temperature

Process temperature is outside limits of

sensor.Failure of sensor may occur if

prolonged.

Check settings C1.7.04 & C1.7.05

Reduce process temperature

Density

Process density over range

Check process conditions

Temperature Drift

Operating temperature has drifted by

>

30 deg C from temperature at zero

calibration.

Perform new zero calibration to maintain

accuracy.

Sensor Signal Error DC component of sensor signal too high

Check sensor resistances

Replace sensor

Resistance Sensor

Defective

PT500 sensor defective. Temperature

measurement & compensation unreli-

able

Check sensor resistances.

Replace sensor