3 storage, 4 lifting, 5 csa dual seal – KROHNE OPTIMASS with MFC 300 EN User Manual

Page 10

10

1

Horizontal intalation with flow from left to right

2

Vertcial installation with flow uphill

3

Angled installation with flow uphill

4

Horizontal installation with long vertical drops after the meter ARE NOT recommended

5 6

Vertical installations with isolation valves fitted for setting the zero calibration. It is rec-

ommended that a valve is fitted below the meter to prevent a reverse flow when the

pump is switched off.

Notes:

Avoid long vertical runs after the meter (

4

). They can cause siphoning and therefore measure-

ment errors. If long vertical runs are unavoidable, then you should use a valve or orifice plate

downstream of the mter in order to the restrict flow.

Avoid mounting the meter at the highest point in the pipeline. Air or gas can accumulate here

and cause faulty measurements.

3.3 Storage

If the meter is to be stored prior to installation, it is recomended that the meter is stored in its

original packaging and that the ambient temperature range does not exceed -50°C or 85°C

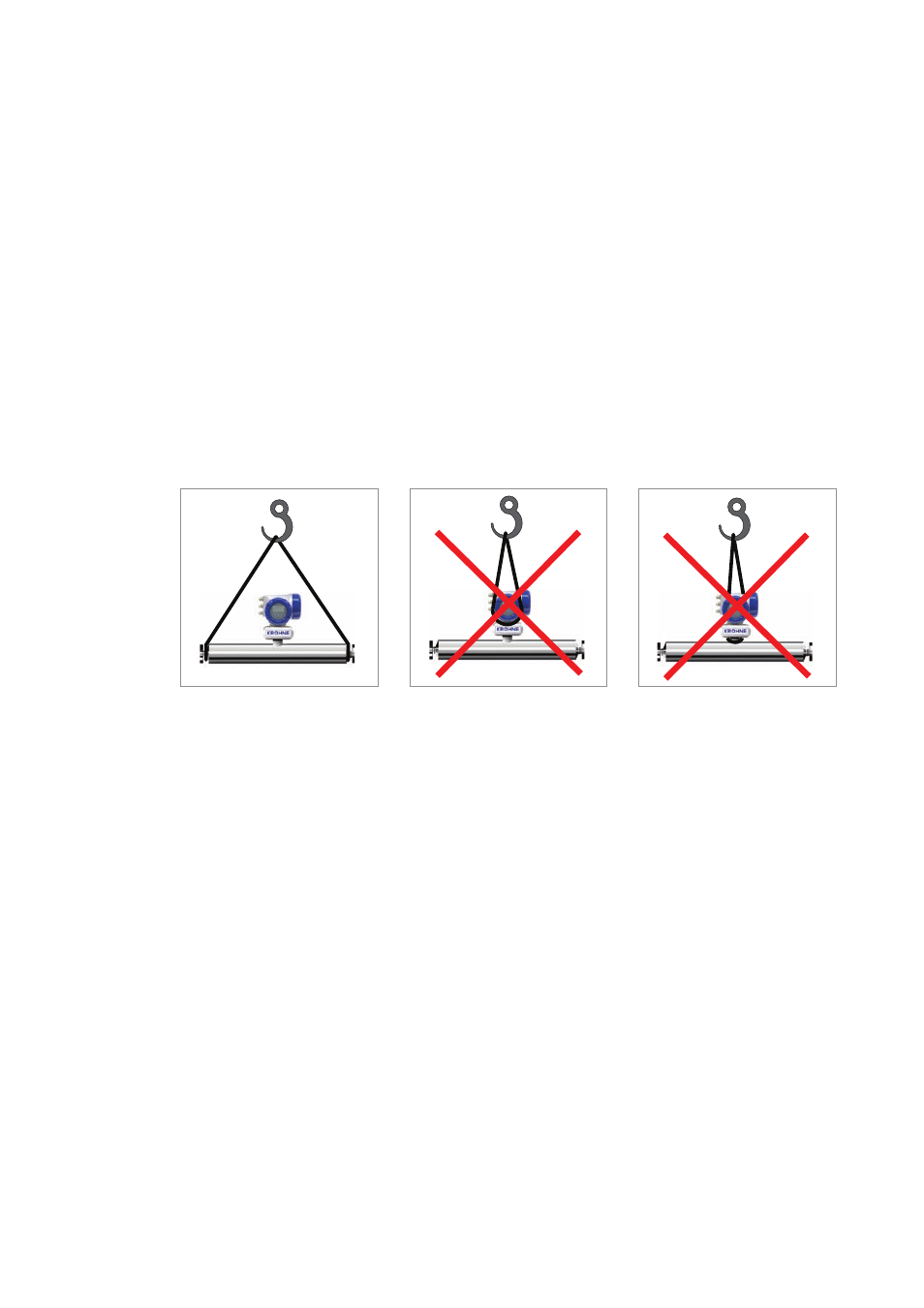

3.4 Lifting

1

Use a well maintained sling to lift the meter by the spigots

2

DO NOT lift the meter by the electronics housing.

3

DO NOT lift the meter by the electronics stem.

NOTE:

The 1000 and 2000 meters have 4 eye holes on the outer tube, 2 each end. These can be used

to lift the meter into place on vertical installations, where the meter is supplied with hygienic

connections. Please be aware, that they ARE NOT suitable for lifting the meter where is has

been supplied with [heavier] flange connections. It is the user’s responsibility to use suitable

lifting equipment.

3.5 CSA Dual Seal

To cover the requirements of ANSI/ISA -12.27.01-2003 “Requirements for Process Sealing

Between Electrical Systems and Flammable or Combustible Process Fluids” a secondary seal

is incorporated into all Optimass/gas products. If the primary seal fails, the secondary seal will

prevent escaping fluid reaching the electronic compartment.

OPTIMASS 1000, 2000, 3000, 7000, 8000, 9000

Liquids (Example model code: OPTIMASS 1000C S25 – LIQUID)

Pressure/Temperature data:

OPTIMASS 1000 / 1300 / 1010 -40°C...130°C and 100...10,000 kPa

OPTIMASS 2000 / 2300 / 2010 -45°C...130°C and 100...14,000 kPa

OPTIMASS 3000 / 3300 / 3010 -40°C...150°C and 100...15,000 kPa

OPTIMASS 7000 / 7300 / 7010 -40°C...150°C and 100...10,000 kPa

1

2

3