Caution – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 71

<4. Pipomg>

4-11

IM 11M12A01-02E

8th Edition : Jan.13,2012-00

CAUTION

• As far as possible do not stop the instrument air flow, to prevent the sample gas from

entering the detector and damaging the zirconia cell.

• Connect the stop valve, which is at the calibration gas inlet, directly to the detector.

If there is piping between the detector and the valve, condensation may damage the sensor

by rapid cooling when calibration gas is introduced.

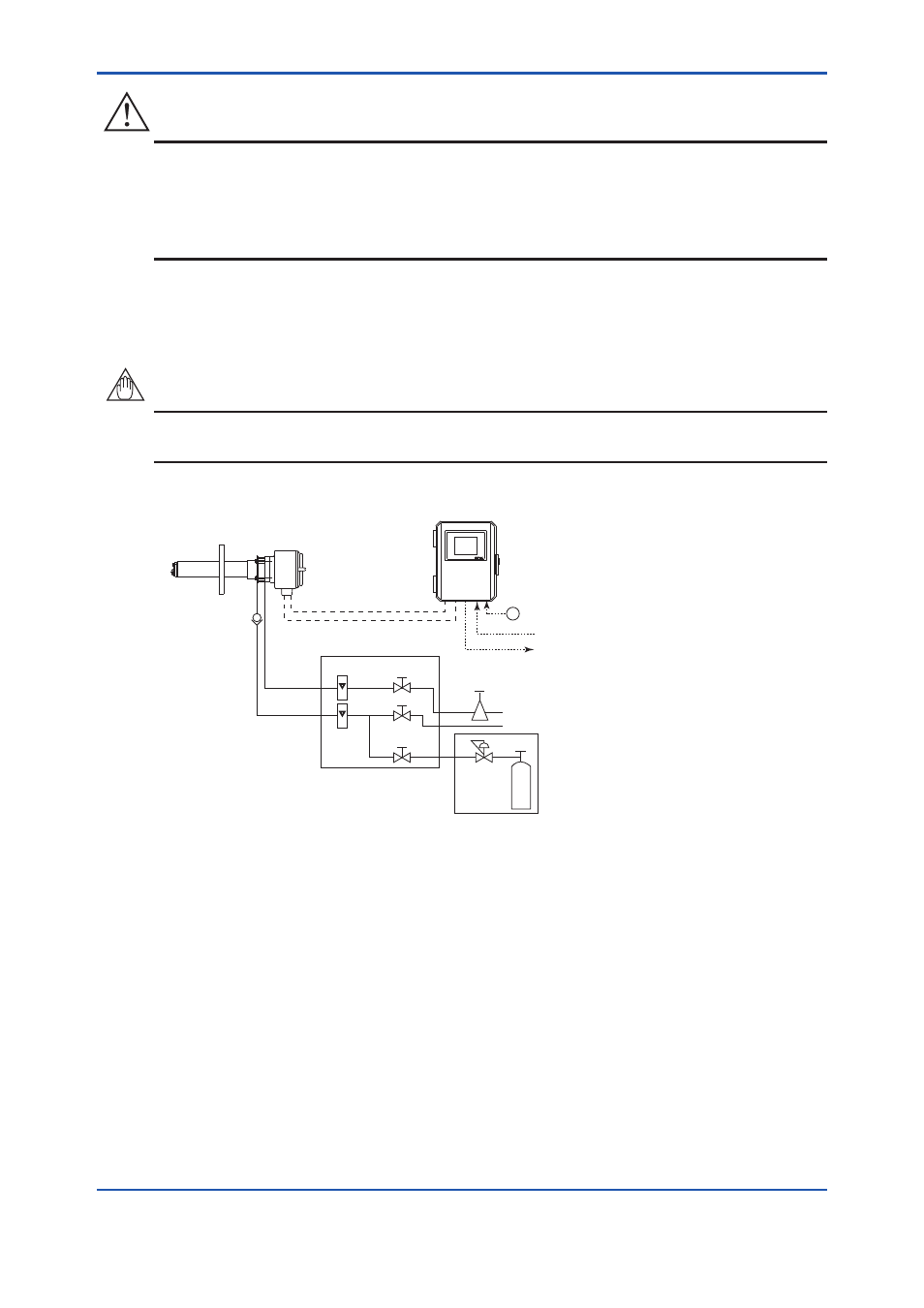

Figure 4.14 illustrates an example of System 2 using a detector with pressure compensation.

Supply air pressure (flow) may vary depending on the furnace pressure. It is recommended to

use a flowmeter and an air set that is suitable for the furnace pressure.

NOTE

• When using the ZA8F Flow Setting Unit and ZR40H Automatic Calibration Unit, please note

that the supplying airflow (pressure) will vary depending on the furnace pressure.

~

ZA8F Flow Setting Unit

EXA ZR402G

ZR22G Separate type

Zirconia Oxygen Analyzer, Detector

ZR402G Converter

Reference

gas

Calibration

gas

Stop valve

or

Check valve

Needle

valve

Flowmeter

Instrument air

Air Set

Pressure

reducing

valve

Zero gas cylinder

Calibration gas

unit case

F4-13E.ai

Span gas

(Same as Zero gas calibration unit)

100 to

240 V AC

Contact input

Analog output, Contact output

Digital output (HART)

Signal

(6-core shield cable)

Heater (2 core cable)

Figure 4.14 System 2 using a detector with pressure compensation