3 system 3, System 3 -3 – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 17

<1. Overview>

1-3

IM 11M12A01-02E

8th Edition : Jan.13,2012-00

1.1.3

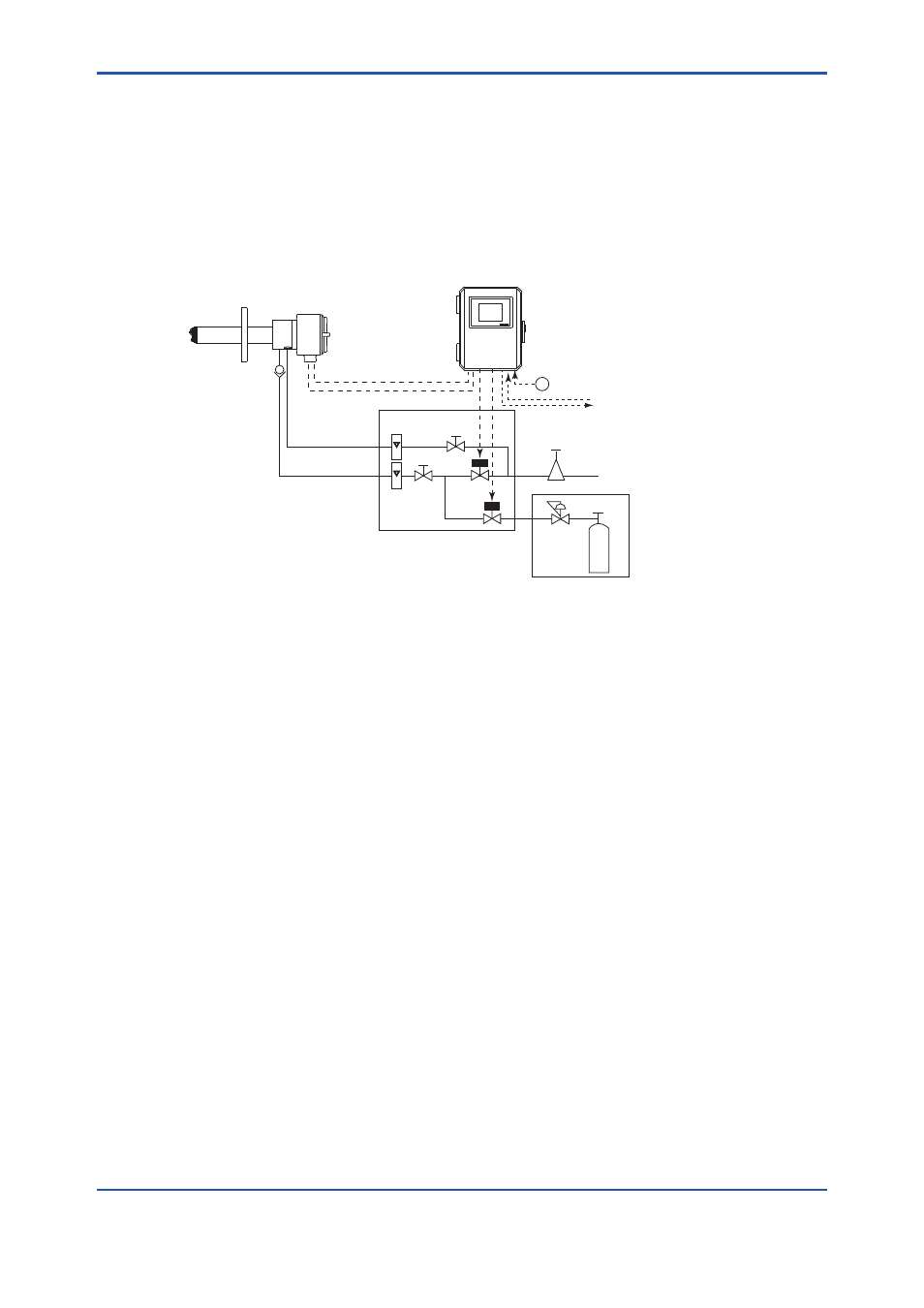

System 3

This example, System 3, represents typical applications in large boilers and heating furnaces,

where there is a need to monitor and control oxygen concentration. The reference gas and

calibration-time span gas are (clean, dry) instrument air. Zero gas is supplied from a gas cylinder.

System 3 uses the ZR40H automatic calibration unit, with auto-switching of the calibration gas.

A “combustible gas detected” contact input turns off power to the heater. There’s also contact

output from the converter that can be used to operate a purge gas valve to supply air to the

sensor.

F1-3E.ai

ZR22G Separate type

Zirconia Oxygen Analyzer, Detector

ZR402G Converter

Signal

(6-core shield cable)

Heater (2-core)

Reference gas

Calibration gas

Flowmeter Needle

valve

Zero gas cylinder

100 to 240 V AC

*3

Check valve

Contact input

Analog output, contact output

Digital output (HART)

Air Set

lnstrument air

Pressure

reducing

valve

EXA ZR402G

*1

*2

~

Calibration gas

unit case

ZR40H

Automatic Calibration Unit

*1

Shield cable ; Use shielded signal cables, and connect the shield to the FG terminal of the converter.

*2

Select the desired probe from the Probe Configuration table on page 1-4.

*3

When a zirconia oxygen analyzer is used, 100% N2 gas cannot be used as the zero gas. Use approximately 1% of O2 gas

(N2-based).

Figure1.3