Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 177

<12. Troubleshooting>

12-7

IM 11M12A01-02E

(4) Check whether the deterioration of or damage to the sensor assembly that caused the

alarm has occurred suddenly during the current calibration in the following procedure:

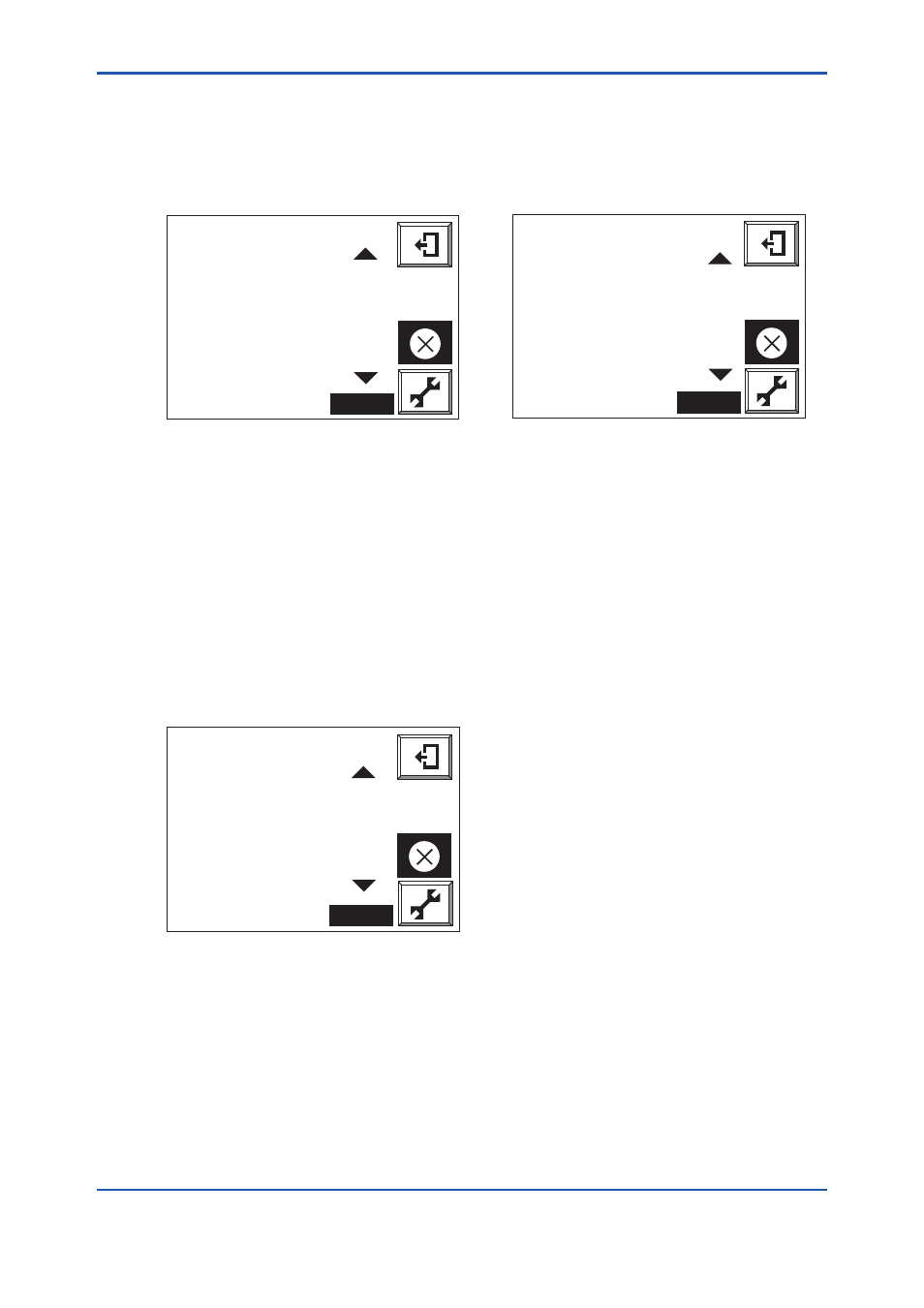

a. Call up the Detailed-data Display.

b. Use the [Page Scroll] key to check Calibration Data (Figure 12.6). The span and zero

correction ratios of the last ten calibration can be checked here. By checking these data,

whether the sensor deterioration has occurred suddenly or gradually can be determined.

Cell voltage:

0 . 6 mV

Thermo voltage:

4 2 . 1 mV

C.J.resistance: 1 1 8 1 . 4 Ω

Cell resistance:

- 4 Ω

Soft.rev.:

0 . 2 4

Tag:

F12.5E.ai

Hold

Calibration data:

1: 2 0 0 0 / 07 / 07 1 4 : 57

Span gas ratio: - 2 . 9 %

Zero gas ratio: 7 0 . 3 %

2: 2 0 0 0 / 07 / 07 1 4 : 5 4

Span gas ratio: - 2 . 9 %

Zero gas ratio: 8 9 . 7 %

Tag:

Hold

Figure 12.5 Detailed Data Display

Figure 12.6 Calibration History

(5) If the sensor assembly has deteriorated suddenly, the check valve that prevents moisture in

the furnace from entering into the calibration pipes may have malfunctioned. If the furnace

gas flows into calibration lines, the gas is cooled and thus condensation develops and

accumulates in the pipe. During calibration the condensate is carried with the calibration gas

and blow onto the sensor assembly, whereby the cell is cooled quickly. This results in the

failed sensor assembly.

(6) If the sensor assembly has deteriorated gradually, check the condition of the sensor

assembly following the procedure below.

a. Use the [Page Scroll] key to check Cell Resistance. It should be 200V or less if the cell

(sensor) is new. On the other hand, if the cell (sensor) is approaching the end of its service

life, it will be 3 to 10 kV.

b. Use the [Page Scroll] key to check Cell Robustness. It should say “Life > 1 year” if the cell

(sensor) is in good condition.

Span gas ratio: - 2 . 9 %

Zero gas ratio: 7 0 . 3 %

Response time: 0 s

Cell robustness: life< 1 month

Cell temperature: 1 0 6 7 °C

C.J.temperature: 4 7 °C

Tag:

Hold

F12.7E.ai

Figure 12.7

12.2.2.3 Alarm 7: Span-point Calibration Coefficient Alarm

In automatic or semi-automatic calibration, this alarm is generated when the span correction ratio

is out of the range of 0 ± 18% (refer to Section 9.1.3, Compensation).

The following are suspected as the cause:

(1) The oxygen concentration of the span gas does not agree with the value of the span gas set

in Calibration setup.

(2) The flow of the span gas is out of the specified flow value (600 ± 60 ml/min).

(3) The sensor assembly is damaged and the cell voltage is abnormal.

8th Edition : Jan.13,2012-00