1 blow back piping, Blow back piping -9 – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 69

<4. Pipomg>

4-9

IM 11M12A01-02E

8th Edition : Jan.13,2012-00

4.3.1

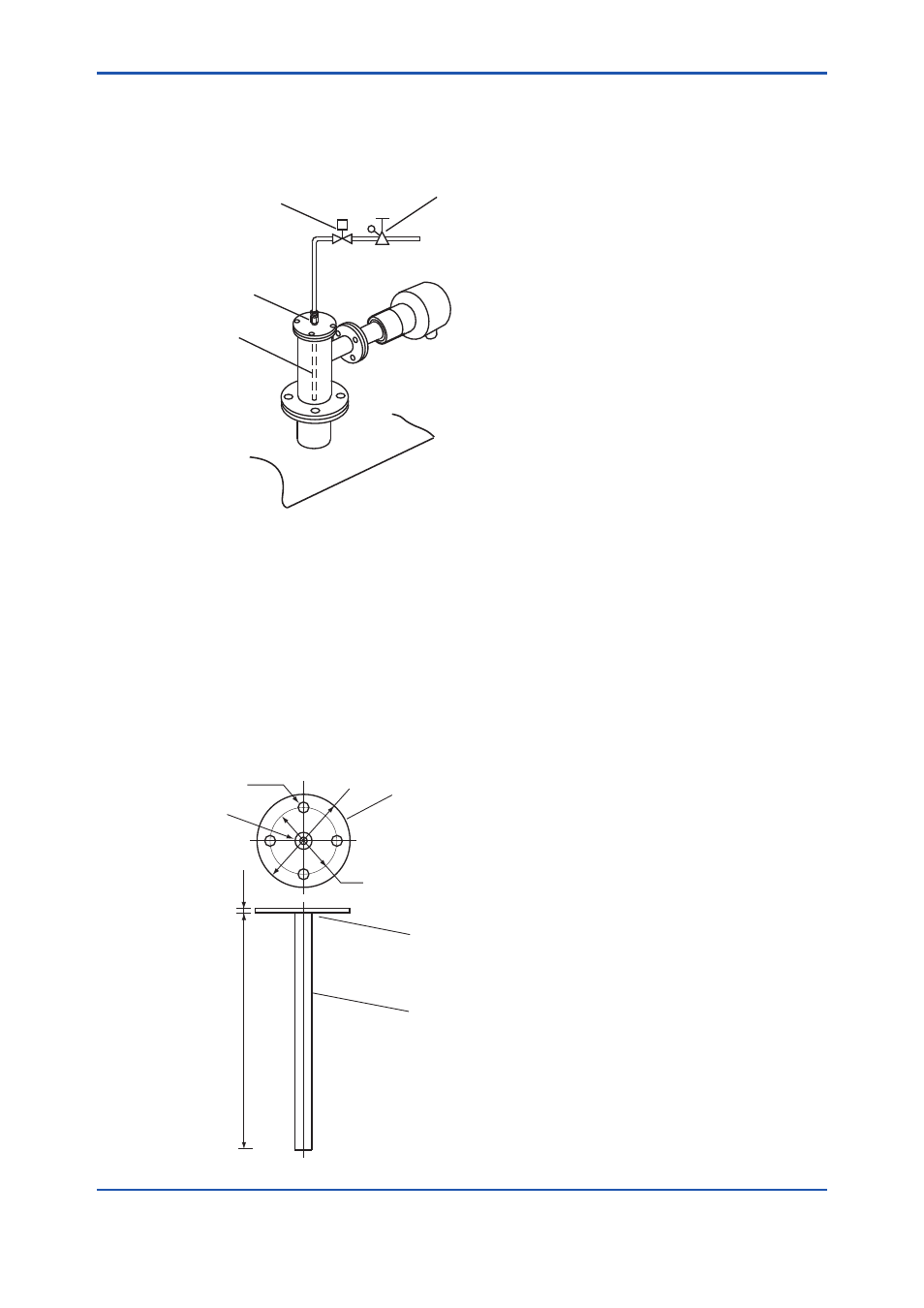

Blow Back Piping

This piping is required when the blow back function is carried out. The piping described below

provides automatic blow back operation when the “ Blow back start “ command is entered to the

converter.

Solenoid valve

Pipe junction

Blow pipe

F4-10E.ai

Pressure reducing valve

Figure 4.11 Blow back Piping

The following parts are required for blow back piping.

• Flange (to be prepared as illustrated in Figure 4.12.)

• Blow pipe (to be prepared as illustrated in Figure 4.12.)

• Two-way solenoid valve: “ Open “ when electric current is on. (Found on the local market) .

• Air set (recommended by YOKOGAWA, G7003XF / K9473XK or G7004XF / K9473XG)

probe adapter.

Approximately

200

Rc1/4

Stainless steel flange

Welded

8 (O.D.) by 6 (I.D.) Stainless steel pipe

F4-11E.ai

Unit : mm

8 ~ 10

Φ

90

Φ

73

4-

Φ

9

Figure 4.12 Manufacturing Blow pipe and Flange